Profiting on waste heat

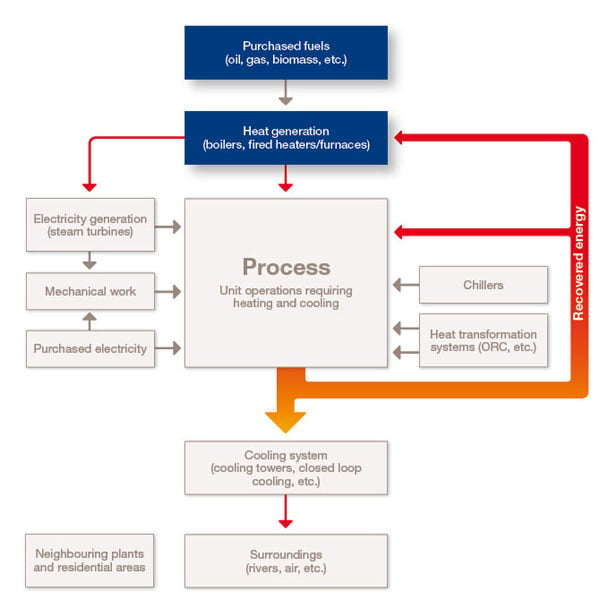

Recovering energy

Industries

Heat exchanger designs

Payback analysis

Contact Us

Saving fuel

Generating electricity and mechanical work

Selling heat and electricity

Reducing cooling needs

Reducing utility investments

Increasing production

Reducing greenhouse gas emissions

Transforming energy

Preheating in interchangers

Direct process heat integration

Indirect process heat integration

Increased number of effects in evaporation systems

Reduced fouling and maintenance

Reduced steam temperature

Generating steam from flue gases

Boosting compressor capacity

Reduced need for chilled water

Improved turbine performance