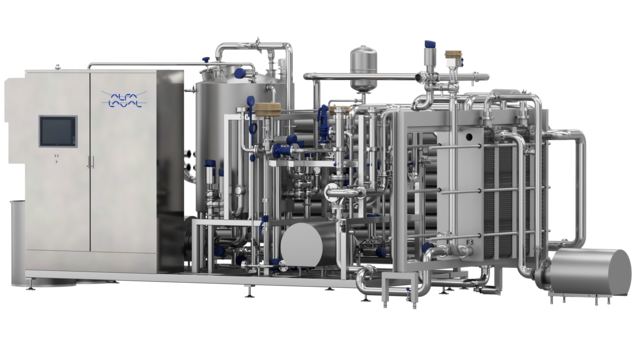

Steritherm PHE

Enhance product microbiological stability by inactivating unwanted microorganisms in process fluids that can causes spoilage. The Alfa Laval Steritherm PHE sterilizes process fluids through a combination of efficient, high temperature heat transfer and holding time. Pre-assembled and skid-mounted, this aseptic thermal module ensures product quality and safety.

Premium plate sterilizer for heat-sensitive products and high heat recovery

- Maximize energy recovery and reuse

- Gentle sterilization of food products

- Space-saving installation for highly efficient sterilization of dairy, food and beverage products

- Global expertise with local support and service

Sterilize your food products – safely, reliably and consistently using the Alfa Laval Steritherm PHE. Pre-tested and validated, this premium plate sterilizer boosts product stability by killing or inactivating microorganisms that cause spoilage. The result? Product uniformity, consistency and integrity.

Flexible and modular, the Steritherm PHE adapts to process requirements and provides accurate 24/7 control of all sterilization parameters. An integral component of any aseptic food packaging line, it easily connects to aseptic tanks and aseptic filling machines, adjusting to variations of the aseptic process.

Optimize food safety and add flexibility to your production processes with the Alfa Laval Steritherm PHE.

How does the Alfa Laval Steritherm PHE sterilizer work?

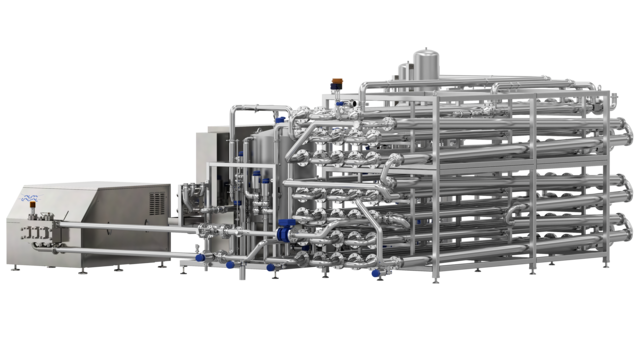

The plate heat exchanger comprises a pack of stainless steel plates compressed in a frame. The frame contains several separate sections in which different stages of treatment, such as pre-heating, final heating and cooling, occur. The heating medium is hot water, and the cooling medium is cold water, ice water or propyl glycol, depending on the requirements.

Corrugated plates with unique plate patterns optimize heat transfer. Supporting points on the plate hold the plates apart and form narrow channels between them. The liquids enter and leave the channels through ports in the plate corners. Varying patterns of open and blind holes route the fluids from one channel to the alternate channel. Gaskets around the plate edges and the ports form the channel boundaries and prevent external leakage and internal mixing.

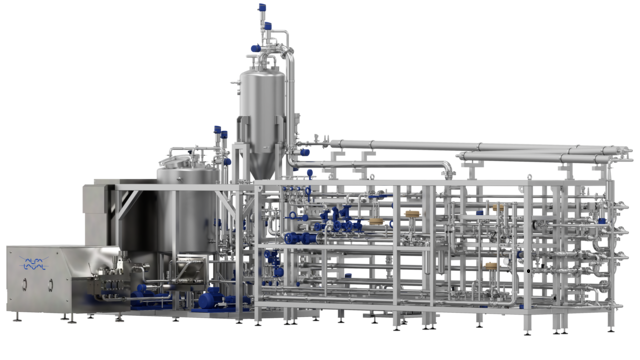

Balance tank

Before production starts, the Steritherm PHE module undergoes sterilization in place (SIP) by culinary steam at 125°C (257°F). Thirty minutes after sterilization, the product flows through the balance tank into the module. A programmable logic controller regulates the speed of the pump forwarding the product to ensure a constant feed rate to the heat exchanger based on signals from a flow meter. A temperature transmitter and a pressure transmitter monitor the product inlet's temperature and the installation’s pressure.

Pre-heating by direct regeneration

Direct energy recovery pre-heats the incoming untreated product, minimizing the demand for heating and cooling media. The hot sterilized product raises the temperature of the cold incoming product in the regenerative heat exchanger section. The treated product is subject to overpressure compared to the untreated product.

Final heating to the sterilization temperature

This is achieved through hot water recirculation. The hot water is produced in a dedicated hot water set through steam. A temperature transmitter measures the product temperature at the heat exchanger outlet and subsequently regulates the steam quantity with a modulating valve. The temperature difference between hot water and product is very low to prevent product burning and plate fouling. The product remains at the sterilization temperature in an insulated holding cell.

Cooling

The product cools to the final temperature in two stages. First, the regeneration section mentioned above cools the product. The second and last stage uses chilled water to cool the product to the desired outlet temperature. The customer supplies the cooling media. A temperature transmitter controls the chilled media, measures the product's outlet temperature, and sends commands to the modulating valve on the cooling media pipeline.

Cleaning-in-place

The module is designed for cleaning in place. Under normal operating conditions, all surfaces in contact with the product are cleanable without requiring dismantling any module parts. The necessary cleaning intervals depend on the products treated and the temperatures applied.

Control system

Automated operation regulates start and stop functions, set point, and piping and instrumentation diagram (P&ID). Control parameters can be reviewed and adjusted. The system displays relevant process data, such as plant status, actual temperatures and flow rate, and alarm status.