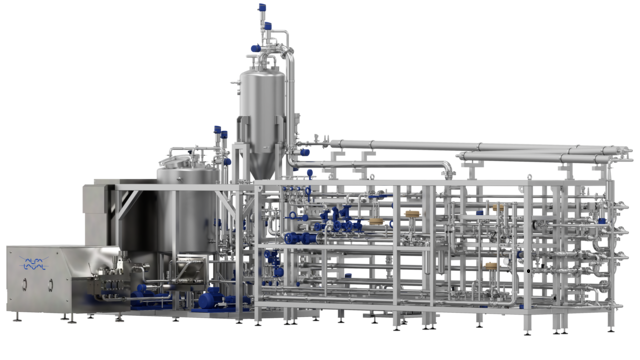

Steritherm DSI

Safeguard product taste, aroma, texture, appearance and nutrients with the Alfa Laval Steritherm DSI. This direct steam injection sterilizer protects the quality of dairy products, fresh beverages, and liquid foods. Continuous ultra-high-temperature (UHT) treatment rapidly heats products to sterilization temperatures for a short time, then quickly cools them before filling into aseptic packaging. It contributes to more production uptime, greater product integrity, and longer shelf life.

More uptime, enhanced product safety and longer shelf life with UHT treatment of dairy, food and beverage products

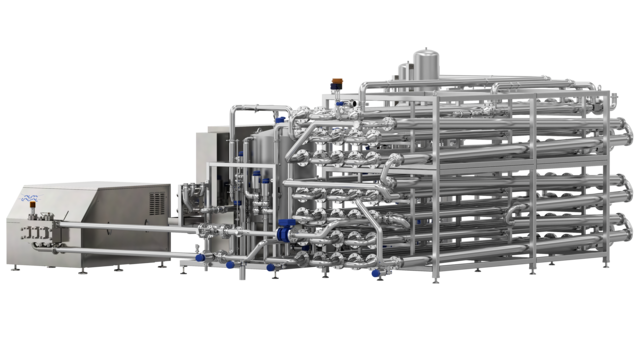

- Minimal thermal impact on heat-sensitive products due to rapid heating and cooling

- More uptime and lower maintenance costs due to direct steam injection and auto diagnostics supervision system

- Enhanced production safety due to verification of critical parameters by an automated FDA-approved recording device

- High energy efficiency and cost savings due to 100% use of the latent heat of steam

- Space-saving footprint that eliminates the need for condensate return systems

Increase product stability while retaining the natural, nutritional and organoleptic characteristics of dairy, food and beverage products. Sterilize heat-sensitive, low-acid or fouling-prone products with the Alfa Laval Steritherm DSI. This continuous UHT treatment module uses direct steam injection helps prevent product browning, overcooking, and protein denaturation.

As an integral component in a complete aseptic bag-in-box production line, the Steritherm DSI module ensures the integrity of products – from soups, sauces and baby food to coconut milk, dairy and non-dairy, or starch-based products. Backed by a global supplier with a local presence, the fully automated UHT sterilizer with an automatic diagnostics supervision system optimizes uptime and production.

How does the Alfa Laval Steritherm DSI work?

Direct steam injection flow chart

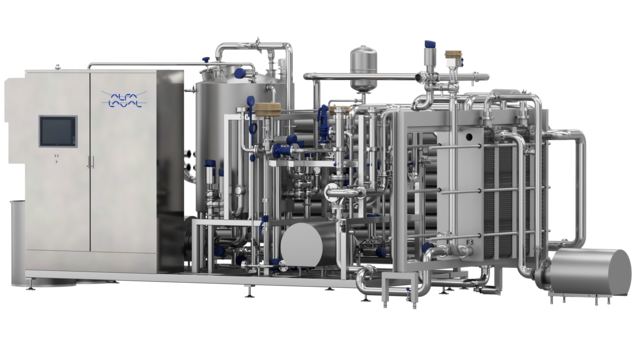

Before production starts, the module undergoes sterilization in place (SIP) by culinary steam. After sterilization is complete, it remains sterile under aseptic conditions. When the aseptic tank and/or filling machine are ready to receive the processed product, production can start.

The product enters the balance tank, the entry point of the Steritherm DSI module. The raw product is preheated by regeneration in an indirect heat exchanger up to approximately 80°C (176°F). Final heating to sterilization temperature takes place in the steam injector by continuous injection of high-pressure culinary steam into the product.

Fully automated, the module maintains product temperature and water content at a constant level. Variations in the differential temperature of more than ±1°C (± 1.8°F) set off an alarm.

Sterilization takes place in the holding tube, where the product remains for the time required at the desired temperature. The product then flows into the flash vessel, which is under vacuum. The pressure and temperature drop to 85°C (185°F) almost instantly. The excess water in the form of vapour flashes off.

The product can enter an optional aseptic homogenizer or be directly introduced into the cooling section of an indirect heater where it reaches the desired filling temperature.