District heating

District heating, also known as heat networks or campus heating, is a system that transports heat to residential and commercial buildings through insulated pipes. This heat can come from a variety of traditional and green sources like combined heat and power, energy for waste, geothermal, solar thermal, and waste heat recovery. Alfa Laval’s energy efficient plate heat exchangers can support all district heating processes, reducing carbon emissions and demand for primary energy at the same time.

Choose the right district energy partner

- With millions of heat exchangers in operation within the industry worldwide and service centers covering all markets, Alfa Laval has a proven record.

- We understand the importance to scale up the use of renewable energy, increase heat recovery and have a strong focus to aid customers and partners.

- Our product range covers everything from heat generation in production facilities, to heating the water in your shower.

- And, with AHRI third-party performance certification, you can rest assured that the thermal performance of our products is as good as we say it is.

- As one of our biggest markets, research and development in district heating is high on our agenda and we are creating with you in mind.

Trends in district heating industry

Today, the heating sector is influenced by multiple trends. These trends are mainly driven by increased expectations and targets in decarbonization, energy supply security and energy affordability, customer usability, and energy-efficient performance.

Some of the focused trends in the district heating sector are:

- Low grid temperature. Newly built grids for low temperature or existing grids where operating temperatures are being lowered

- Energy sources: changing fossil fuels to renewables and recycled energy

- Centralized production is complemented by decentralized/local production

- New flexible solutions in terms of supply and network size

- Trend in the sector to work more long-term with investments, digitalization and asset management

- Extended involvement and interaction with the end user to work with energy efficiency and reuse heat. Some customers can be viewed as “Prosumers” – both consumers and producers – not only using but also delivering energy to the grid at times.

Recovering industrial waste heat with heat exchangers and using it for district heating is one of the most effective ways to improve energy efficiency on a global scale. The Aurubis Group has taken this very approach to improve sustainability in one of their smelters.

District heating from first to fifth generation

Alfa Laval has a wide range of special heat exchangers developed for the HVAC market and we have been working actively with the district energy sector for more than 70 years.

Heat exchanger have played a vital role in district heating systems from the start of generation 1 technology and the importance of their functionality are increasing for the new generations of district heating, district heating generation 4 and generation 5.

Together with consultants, system builders, energy companies and our partners we are driving the transformation of the energy landscape. We are proud to be change agents in this energy transition. Do not hesitate to contact your local Alfa Laval office to hear more about the solutions of tomorrow.

District heating generations - From first generation steam grids to fifth generation low temperature grids with distributed heat pumps. Temperatures are decreasing and the efficiency of the systems are increasing.

Alfa Laval Solutions in District heating

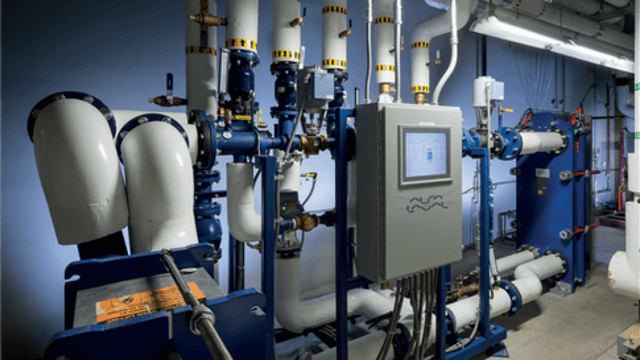

In the district heating industry Alfa Laval is supplying heat transfer solutions for energy generation and for substations connecting buildings to the distribution network. Low return temperature increases the efficiency of the total district heating system and should always be the main target for any grid operator.

Production

1. Energy Generation in transformation

Alfa Laval heat exchangers are used to extract heat from the source. The trend is going towards more renewable energy, recovery of excess heat from new energy sources like data centres. And some energy companies are exploring the possibilities of green hydrogen.

2. Heat pumps are used by district heating operators turning excess heat at low temperatures into an affordable and sustainable heat source

Alfa Laval heat exchangers are also used in heat pumps of all different sizes. Heat pumps can be used in connection with for example a wastewater treatment plant to generate energy for a district energy network. A heat pump can also be located in a commercial building reusing the heat from for example a restaurant or a smaller data center locally. In many installations in heat-efficient buildings, the heat pump is used to produce both heating and cooling depending on the needs.

Distribution

Grids

In some locations heat exchangers are used as pressure breakers in extensive networks with height-related issues and altitude differences. This can be when interconnecting city-scale networks or large distribution grids coming from a production facility located, sometimes far away, and at a higher altitude than the city using the district heating. The heat exchangers will work as pressure breakers in these applications.

Heat exchangers are mainly used as pressure breakers in substations. Either in substations between the main network and a secondary network or from the distribution network to each building.

A secondary heating network enables low-temperature systems, where the incoming water to the end users can be of a lower temperature than the primary grid. With low-temperature systems, an entire area can receive heat from a shared heat substation.

Demand

End User

Heat exchangers are one of the main components in district heating substations at the end user/building level.

Heat exchangers are needed for two main reasons. Firstly, they are used to isolate and protect the individual building's heating system and users from the potentially higher pressure and temperature available in the main distribution network. Secondly, it is a way to limit the amount of damage one could incur if there is a leak inside a building's heating system as the pressure breaker ensures that there is a limited amount of heating water in the isolated heating circuit.

Gasketed plate-and-frame heat exchangers

- Flexible solutions that can be adapted to the duty ensuring highest thermal efficiency

- Compact designs save space and are easy to service and maintain

- Solutions to reduce fouling, stress and corrosion for maximum uptime

Semi-welded plate heat exchangers

- Highly efficient, reliable technology for applications that can cause pressure or temperature fatigue

- Guaranteed long sealing lifetime thanks to unique Alfa Laval RefTight™ sealing system

- A dependable solution for preventing cross-contamination between media

Brazed plate heat exchangers

- Lightweight copper-brazed construction with compact footprint

- Greater thermal efficiency than comparable shell-and-tubes

- Flexible options to fit a variety of applications with all different types of media/fluids

- Ideal for natural and low-GWP refrigerants

Fusion bonded AlfaNova heat exchangers

- True 100% stainless steel construction

- Strong corrosion resistance with aggressive media

- Prevents metal contamination in drinking water and other hygienic applications

- High thermal efficiency and compact footprint

Consultant? System integrator?

Are you a consultant? Look here! With expertise from decades of experience in heat exchange, Alfa Laval offers knowledgeable resources for today’s heating and cooling challenges. Discover answers to complex questions on everything from energy efficiency to natural refrigerants, along with helpful tools that make it simpler to find the right technology for your application.

AHRI-performance-certified heat exchangers for confident thermal performance

Certification from the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) is the only global third-party verification of thermal performance, giving you independent assurance that your plate heat exchanger will perform in accordance with the manufacturer’s published ratings. Alfa Laval offers AHRI-certified gasketed plate heat exchangers, brazed plate heat exchangers, and fusion-bonded plate heat exchangers.

Making efficiency last for decades

A poorly functioning heat exchanger may affect safety, product quality and energy costs. Failure may lead to costly downtime and major losses in production. By regular and proactive maintenance of your gasketed plate heat exchanger performance is preserved and operations kept trouble-free and predictable.

We have the expertise to help you whether you experience a problem today, wish to prevent future issues or want to solve the problem yourself with our online troubleshooter.

Digitalization for energy efficiency

Smart cities and digital intelligence could help cities to make progress toward meeting 70 percent of their Sustainable Development Goals. Digital services can already have a significant impact on heating and cooling systems in cities, making them more sustainable.

Enabling remote monitoring and performing dedicated analytics allow more precise and efficient operation, more informed decision-making, and targeted interventions. The development of more sophisticated and efficient heating and cooling systems is only possible through this digital transformation, which can provide reliable and affordable heating and cooling services to urban areas while reducing greenhouse gas emissions.

HVAC and the Sustainable cities

Consuming more than two-thirds of the world’s energy, our cities play a crucial role in tackling the climate crisis. A considerable part of cities’ energy consumption is for heating and cooling, which means improving energy efficiency is paramount. Alfa Laval has almost a century of experience in heat transfer and recovery and aims to become carbon neutral by 2030. Let us be your partner in the transformation to a sustainable tomorrow.