Fish meal processing

Enhance your fish meal production with Alfa Laval as your partner. Our components and processing systems empower you to increase yield, minimize environmental impact, and raise product quality.

We provide centrifugal-based separation solutions that enable the production of low-fat, high-protein fish meals with exceptional quality and high market price. Our compact evaporation systems ensure low energy consumption and operating costs.

Our solution is designed for water start-up, securing pasteurization and easy flush-through cleaning to ensure minimum residue product after shut-down. This will improve hygiene and reduce bacteriological issues, as well as plant odour issues.

Upgrade your fish meal plant with Alfa Laval technology

Alfa Laval offers a wide range of components and solutions for fish meal plants, enabling easy upgrades of existing systems. Replacing key components in an existing fish meal processing plant with Alfa Laval equipment can significantly improve yield, quality, OPEX, and production capacity.

We can be your partner for the conventional fish meal process

Alfa Laval provides upgrade opportunities for all the key stages in a typical fish meal process line: heating, separation, and stick water concentration before drying.

Process description

1. Heating

In the conventional meal plant, the raw material is heated to coagulate the protein and release the oil while reducing the viscosity. The design of the heating equipment and the ability to maintain the temperature significantly impact product quality and the subsequent separation stage, as better coagulation and precise temperature control lead to improved protein separation.

Traditional fish cookers often provide inefficient, slow heating, resulting in inferior coagulation and a subsequent poor separation – this is especially noticeable for small fish species and offcuts and viscera. The stick water will then contain unnecessarily high levels of fine suspended solids, which, in turn, causes the evaporator to be less efficient. As a result, more water will have to be removed from the dryer, leading to higher energy costs. Fast and efficient heating is also vital for product quality since extended retention at intermediate temperatures causes product degradation.

By upgrading a traditional cooker to an Alfa Laval heating system, you get fast and precise heating and efficient protein coagulation, ensuring the highest possible separation performance and product quality. In addition, the low retention time and processing temperature in an Alfa Laval heating system minimize the release of volatiles, substantially lowering BOD levels in the wastewater. Furthermore, the system's capability for water start-up ensures complete pasteurization from start to finish while facilitating thorough cleaning through flush-through processes.

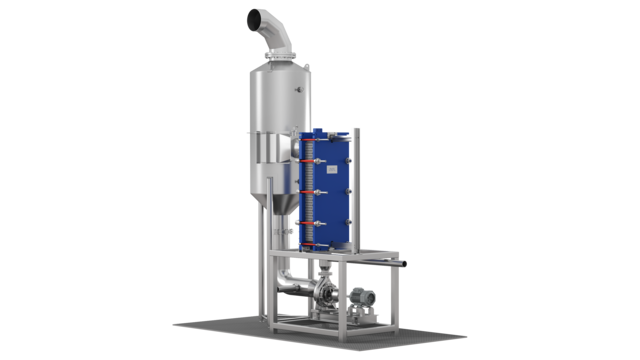

3. Stick water concentration

The water fraction from the separation stage, the stick water, contains some of the raw materials’ most valuable proteins. These proteins are characterized by high digestibility and are increasingly used as palatants in pet food and fish feeds. The stick water is sent through a concentration stage comprising an evaporation and/or membrane system to extract the protein.

Alfa Laval’s AlfaVap and AlfaFlash evaporators are based on plate technology, making them more efficient than traditional falling-film evaporators for fish press water processing. Replacing an existing falling film evaporation system with an Alfa Laval solution enables you to use waste heat as a cost-efficient heat source and achieve major OPEX savings.

The forced circulation system in an AlfaFlash evaporation system enables higher concentration levels and viscosities than in falling film evaporators, meaning more water can be removed from the evaporator instead of the dryer, resulting in substantial energy savings. It also minimizes CIP downtime and increases overall plant capacity when drying is a bottleneck.

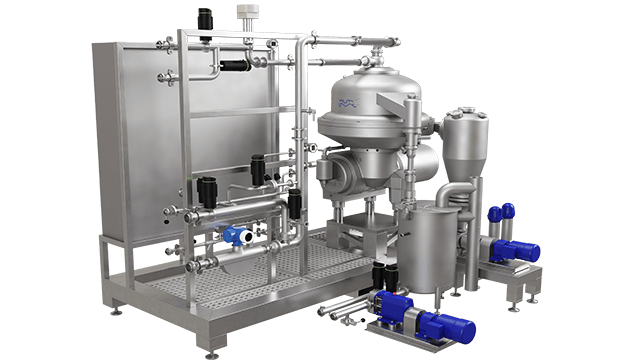

2. Separation

In the separation stage, the suspended solid material is separated from the oil and the water containing the water-soluble solid material. The choice of separation technology has a substantial effect on overall process efficiency. Upgrading a traditional strainer or screw press solution to an Alfa Laval solution based on high-performance decanter and separator technologies brings numerous advantages in terms of yield, throughput, and cleanability.

To increase the oil yield and minimize oil content in the fish meal, boosting protein content, we recommend you upgrade your existing system to a double-stage decanting solution. Here, the first decanter, an Alfa Laval Oil Plus, extracts the oil, and the second separates water from solids. This setup allows for higher oil yield, premium quality, and up to 50% lower oil content in the final fish meal.

In addition, the move from press to centrifuge-based separation moves your process from a size separation to a density-based separation. This eliminates the need for press compressibility and allows your plant to operate effortlessly with wetter and softer raw material.

4. Drying

In the final stage of the process, the protein fraction is dried to the desired moisture level. Drying is the single most energy-consuming and costly part of the process. With smart upgrades in the upstream stages, most of the water can be removed from the stick water before the dryer, with considerable reductions in energy cost as a result.

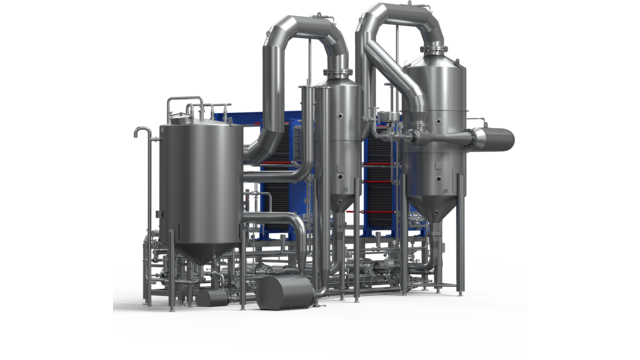

Alfa Laval Centriflow – The optimum wet rendering systems for fish meal and fish oil production

Alfa Laval Centriflow is a complete processing solution for the production of high-quality fish meal and fish oil. It comprises Alfa Laval’s industry-leading solutions in all the key process stages: heating, separation, fish oil purification, and energy-efficient stick water concentration.

A Centriflow system is optimized on a system level for maximum performance and offers several benefits over traditional fish meal/oil production systems:

- Exceptional cleanability, enabling food- grade processing of both oil and protein.

- Fast heating to secure oil and protein quality

- Outstanding yield

- High throughput

- Unparalleled fish meal and fish oil quality

- Short turnaround times

- Proven technology with high operational reliability

The Centriflow system supplied by Alfa Laval includes the following process steps:

1. Size reduction to maximum 12 mm (½")

2. Pump through the heating system:

- Contherm Scraped Surface Heat exchanger for high-end airless heating with indirect steam

- DSI heater for efficient fouling-free fast heating system

- Either as a combination system or individual, depending on the customer's preference

3. Intermediate heating tank to secure demands to holding time

4. Centrifuge-based separation:

- 3-phase decanter followed by a HSS purifier for compact, efficient and cost-effective separation

- A low-fat, high-protein processing concept will include an Oil Plus decanter before the 3-phase decanter and an AFPX high-speed skimmer centrifuge.

5. A vacuum dryer is used to remove residue moisture and dissolved oxygen from the fish oil.

6. Optimized evaporation solution based on Alfa Laval's superior AlfaVap and AlfaFlash plate technology.

7. Option for drying:

- Disc dryer for drying of concentrate and solids, delivering waste heat for energy-optimized evaporation.

- Contact drum dryer for separate drying of stick water concentrate

- Options for special hot air flash drying solutions are available per request.

8. Options for efficient meal cooling and milling.

Options for optimized utilization of blood water from unloading and storage

Raw materials

- Whole fish

- By-products from filleting operations

- Shrimp

- Krill

Centrifuges for fish oil and fish meal processing

Alfa Laval offers a complete portfolio of decanters and separators for fish meal and fish oil production.

Characterized by high separation performance, low energy consumption, and excellent hygiene, they are perfect for all types of fish meal processing.

With Alfa Laval centrifuge equipment, you can eliminate the dependence on raw material structure, which will enable you to reduce the oil content in your fish meal by around 50 %, all thanks to our unique separation solutions, such as our Oil Plus decanters and highly efficient AFPX centrifuge range.

Profit from the growing market for high-quality pet food

An increasing number of pet owners are switching their pets’ diets to premium options, causing a rapid growth in the market for high-quality protein meals.

Thanks to excellent hygiene and cleanability, Alfa Laval systems are ideal for producing food-grade protein meals suitable for use in high-quality pet food.

Get in touch with our experts to explore how you can capitalize on this thriving market.

Increase protein yield with blood water handling

Up to 5% of the protein from the landed fish is lost in the water used for raw material handling (also known as blood water). Alfa Laval provides solutions for recovering this valuable protein, allowing you to increase protein yield and significantly reduce the strain on your wastewater treatment system.

Alaskan fishing company recovers fish oil from stick water

Westward Seafoods, an Alaskan fishing company, increased fish oil production by 1.5% after installing an Alfa Laval AFPX separator that extracts fish oil from stick water.

Thanks to the Alfa Laval separator, the company can cut energy costs, meet strict environmental legislation, and create value from waste.

Higher product quality and lower energy consumption

Marine Functional Vietnam (MFC) is a leading manufacturer of protein hydrolysates for food and animal feed applications. A close cooperation with Alfa Laval has allowed the company to reduce its energy consumption by 40% while raising product quality.

Quick and qualified service

With Alfa Laval as your trusted service partner, you can rely on prompt and qualified assistance whenever and wherever you need it, even in the most remote locations. Our global network of service offices provides professional support throughout all phases of your operations, including troubleshooting, regular maintenance, advanced performance audits, and predictive maintenance.

Utilizing our remote services, we provide instant assistance via digital channels. Our field technicians can be swiftly dispatched to any site or harbour worldwide if you need on-site support.

Our strong local network makes us the ideal service provider for companies with global operations, fostering closer cooperation and reducing administrative burdens. Put your trust in Alfa Laval for comprehensive service solutions, guaranteeing uninterrupted operations regardless of location.