Foodec Oil Plus

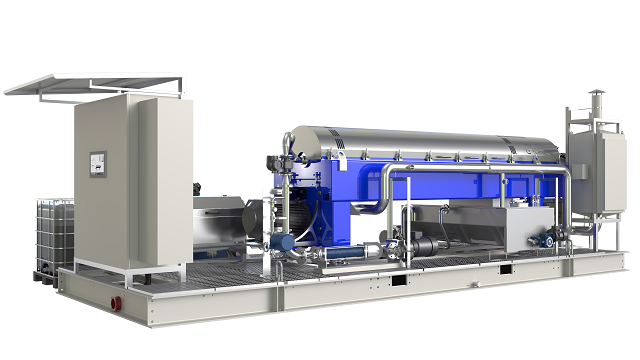

Alfa Laval Foodec Oil Plus decanters are ideal for extracting oil in processes such as fish rendering, meat, and poultry processes. With its innovative design, Oil Plus decanters efficiently achieves maximum extraction of valuable oil, ensuring maximal utilization of raw material. It is easy to operate and maintain, giving you minimal payback time and total cost of ownership. Available a standalone component or a plug-and-play skid, that can easily integrate into your current plant and process.

Recover every drop of value

- Long retention time, maximizing oil extraction

- The extracted oil has oil purity close to 100% that it requires minimal further processing

- Low total cost thanks to low energy consumption and maintenance costs, resulting in short pay-off time – often less than 1 year

- Available as a plug-and-play skid

- Minimal change in your process, you only add a new component

How it works

The incoming feed is effectively separated into oil and wet solids. To do this, the product is sent into a rotating bowl through a tube and accelerated by a rotor. Inside the bowl, a special screw conveyor helps efficiently separate the oil. This is done by using centrifugal force, which makes the lighter oil rise to the top while the heavier solids sink to the bowl's inner wall. Throughout the cylindrical part of the bowl, the oil is continuously extracted.

Foodec Oil Plus decanter centrifuges are very robust with regard to varying flow conditions and are able to deal with high levels of solids in the feed as well as high fluctuations in oil content – with no need for operator’s intervention. They are very easy to operate, and clean using flushing/CIP programs. The oil obtained is exceptionally clean, with very little further processing required.

Fish processing

In wet rendering processes for fish, the addition of a Foodec Oil Plus decanter can boost the oil extraction rate by as much as 3%. This not only increases the revenue from the oil fraction, but also raises the market value of the protein due to the lower fat content. As an added benefit, the extracted oil is so clear that further processing in a high-speed separator can be kept to a minimum.

Service

Maintenance of Foodec decanters is key for ensuring optimum process performance and best possible hygienic conditions.

Depending on process conditions (running time, type of raw, process temperature, number of CIP cycles etc.), Alfa Laval recommends having:

- a decanter inspection at least every 4-6 months

- a major service at least every year.

Qualified Alfa Laval field service engineers can perform inspection and service either on site or in an Alfa Laval service center.

Maintaining bowl and conveyor in good condition is essential for hygienic process conditions and process performance. Bowl and/or conveyor repair is done at an Alfa Laval service center.

With connected services such as remote support and monitoring maintenance intervals can be extended. Maintenance, repairs, condition and remote monitoring can be bundled in a Service Agreement, tailor to your particular needs.

Alfa Laval also offers trainings for on-site maintenance staff.

Contact our dedicated service expert for a Service Agreement offer that is specially tailored to your needs.