BB and BM series

The Alfa Laval BB and BM Series offers the most advanced solutions for bactofuge milk processing, specializing in bacteria and spore removal in the dairy industry. These separators incorporate patented Alfa Laval technologies, delivering exceptional efficiency, reliability, and cost-saving performance, making them ideal for high-quality dairy production.

Advanced technology for bactofuge milk processing

- Alfa Laval’s unique bottom-fed Hermetic Design™ provides superior skimming efficiency and maintains premium product quality

- The bottom-fed design reduces shear forces for gentle product treatment that preserves the size of the fat globules

- Hermetic seals on inlet and outlet prevent oxidation and reduce the foaming of the milk

- Easy adaptation to process conditions provides increased production flexibility and efficient CIP

- Energy savings of up to 60% thanks to the Hermetic Design™

Alfa Laval sets the market standard with the Bactofuge® design

Saving energy, cutting costs

Alfa Laval separators with Hermetic Design are the most energy-efficient on the market. When our unique eMotion technology is added, minimized air friction brings additional power reduction. Combined, our unique design and technologies can deliver up to 70% energy reduction compared to non-hermetic alternatives on the market.

Sustainable is our standard

Alfa Laval wants to help dairy producers make optimal use of every resource in their process. That’s why we build high-efficiency dairy separators that prevent product waste while consuming less energy and water, thanks to unique innovations. Letting you deliver top-quality products that leave a smaller environmental footprint.

Features that make the difference

What sets Alfa Laval separators apart is what’s on the inside: a broad scope of unique and patented technologies that, taken together, help dairy customers achieve improved product quality along with superior hygienic confidence. They also make it possible to drastically decrease both water and energy consumption, reducing both operational costs and environmental footprint.

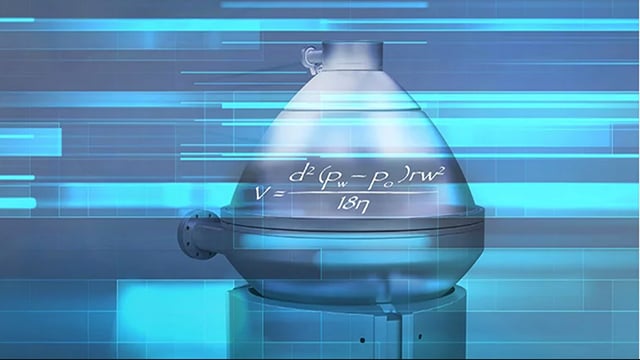

Hermetic Design™

Gentle acceleration, powerful efficiency

A unique air-tight bowl that enables improved product quality and drastically reduces power consumption.

eDrive™

Mechanical simplicity for higher efficiency and lower costs

A direct-drive system with fewer rotating parts that minimizes both maintenance and energy costs.

UniDisc™

New levels of capacity and hygiene

A radical new disc design that decreases cleaning needs while increasing flow rate by up to 20%.

eMotion™

Double the output per kWh

An innovation to minimize friction, which cuts the separator´s energy consumption and CO2 footprint by up to 70%.

Bactofuge®

Outstanding solids capacity

Continuous solid discharge ensures an intact and highly concentrated stream for onward processing or as a valuable by-product. This makes it possible to increase separation capacity.

Separators for every application

Alfa Laval was born from the invention of the modern milk separator. Today, we cover the full scope of dairy separation applications. With unique innovations to increase profitability and sustainability in your process, no matter your product. Check our full portfolio!

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

Contact us to find our dairy partners

Alfa Laval separation equipment plays a critical role in all types of dairies, in all parts of the world. To best serve this market, we work with Tetra Pak as our Global Alliance partner and other selected process integrators in selected regions. Please contact us to connect to an Alfa Laval partner in your region.

The Separator Innovator

Alfa Laval invented the first disc stack separator over a century ago. Since then, we have led the way by constantly improving and reinventing centrifuge technology. Making it safer, more efficient, and more sustainable. Visit our Separator Innovator knowledge base and discover how we continue to revolutionize separation processes across industries.