BTPX

Alfa Laval BTPX is an automatic centrifugal separator for precipitated proteins, microbial broths, hormones and other biopharma applications. It embodies more than 100 years of technical know-how and product development and delivers the performance of production machines in pilot or medium scale set-ups. Designed and manufactured to deliver excellence, this solid-liquid separator can be used as a clarifier or a purifier and concentrator.

BTPX is sterilizable and contained to ensure the integrity of your valuable products

- Low product loss and drier solids thanks to rapid and distinct discharge action

- Highest levels of hygiene – flushing nozzles spray the outside of the centrifuge bowl and the inside of frame hood

- No risk of product /environmental contamination – design of seal system ensures efficient containment

- Efficient operation – temperature control and low noise from cooling jackets around centrifuge bowl

The BTPX is delivered as a fully automatic, plug-in, separation system and can deliver the performance of production machines from pilot to medium scale production.

The BTPX separation system is steam sterilizable and has cleaning-in-place capability. A specially designed seal system provides efficient containment and eliminates the risk of product or environmental contamination.

Cooling jackets surrounding the BTPX centrifuge bowl give efficient temperature control and also contribute to a low noise level. The “dosing ring” solids-ejecting system with fast and distinct discharge action ensures low product losses and drier solids. Flushing nozzles spray the outside of the centrifuge bowl and the inside of the frame hood for maximum hygiene.

How it works

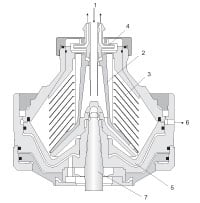

The feed is introduced to the rotating centrifuge bowl (fig 1) from the top via a stationary inlet pipe (1), and is accelerated in a distributor (2) before entering the disc stack (3). It is between the discs that the separation of the liquid phase and the solids phase takes place. The liquid phase moves towards the centre of the bowl from where it is pumped out under pressure by means of a built-in paring disc (4).

The feed is introduced to the rotating centrifuge bowl (fig 1) from the top via a stationary inlet pipe (1), and is accelerated in a distributor (2) before entering the disc stack (3). It is between the discs that the separation of the liquid phase and the solids phase takes place. The liquid phase moves towards the centre of the bowl from where it is pumped out under pressure by means of a built-in paring disc (4).

The heavier solids phase is collected at the bowl periphery, from where it is discharged intermittently via the centrifuge cyclone. The solids discharge is achieved by a hydraulic system below the separation space in the bowl, which at preset intervals forces the sliding bowl bottom (5) to drop down, thus opening the solids ports (6) at the bowl periphery. The bowl is mounted on a vertical spindle (7) driven by a horizontally mounted motor, via a worm gear.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.