Plant-based protein and vegetable processing systems

Rising global demand for alternative proteins is accelerating investment in advanced vegetable-processing systems to extract, isolate, and purify plant-based proteins. Modern systems enable efficient, plant-based protein extraction, reducing energy and water consumption while delivering high purity, quality, and yield. From oilseed to starch crops, Alfa Laval solutions ensure reliable throughput, enhanced texture, and superior nutritional value for large-scale, plant-based protein manufacturing.

Enhancing yield and quality in plant-based protein manufacturing

- Complete utilization of raw material

- High hygiene standards

- High purity, high quality and high yield

- Reduced energy and water consumption

- Minimized freshwater intake and environmental impact

Turning oilseed crops (soybean, rapeseed, sunflower) and starch crops (pea, chickpea, fava bean, mung bean) into high-quality food-grade proteins requires a robust, high-throughput protein-processing system. Optimized vegetable processing systems improve purity, texture, and nutritional value while ensuring efficient resource use.

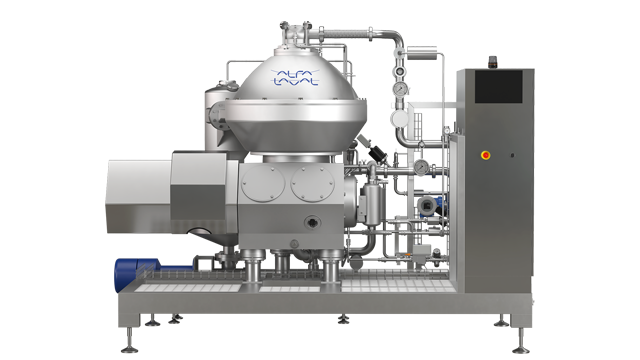

Alfa Laval provides complete, energy-efficient plant-based protein processing systems that cover extraction, isolation, purification, by-product recovery, process water reuse, and wastewater treatment – to meet global demand for protein-rich alternatives to meat.

Food and beverage manufacturers rely on Alfa Laval’s expertise to design, test, and scale vegetable-protein processing systems from pilot to commercial operation.

Broad vegetable processing systems portfolio for plant-based proteins

Alfa Laval offers a comprehensive range of vegetable processing systems for plant-based proteins, focusing on wet fractionation for extraction, isolation, purification and by-product recovery. Whether you need a reliable stand-alone protein system or a complete production line, we support oilseed and starch crop protein manufacturing with modular, customized solutions, including:

- Slurry preparation

- Protein extraction, separation, and purification

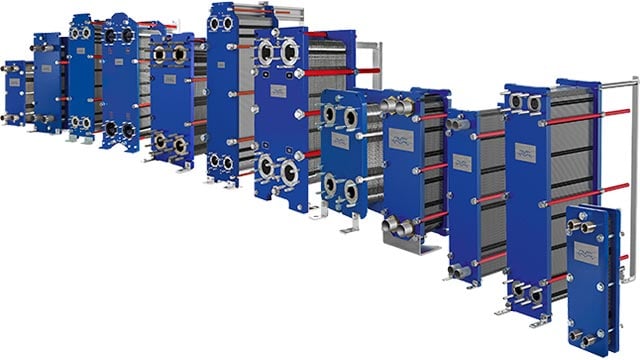

- Pasteurization systems

- Fibre and starch separation and purification

- By-product recovery

- Wastewater treatment and water recovery

Alfa Laval oilseed processing systems

-

Solubilization. The first step is mixing a lye solution with oilseed white flakes, increasing the resulting slurry’s pH value to make the protein soluble.

-

Protein extraction. Next, the slurry is processed in an extraction decanter to separate the solubilized protein from the solids (fibre).

-

Second extraction. The solid cake is then washed with water to release additional protein not extracted during the initial solubilization. A second extraction decanter then separates the resulting slurry into the solids (fibre) and liquid. The solids from this stage can be sent to a dryer or to a biogas plant.

-

Protein precipitation. The liquid collected from both extraction steps is processed to lower its pH value to the protein’s isoelectric point, causing the protein to precipitate. The precipitated protein slurry is then fed into a protein decanter, which separates the precipitate from the liquid.

-

Protein washing. In the last step, the protein is washed with water to increase purity. This results in a protein product with higher purity and better organoleptic properties. However, omit this step if a high-purity protein product is not required.

Alfa Laval starch crop processing systems

-

Solubilization. The first step is mixing a lye solution with flour to make the protein soluble by increasing the pH value of the resulting slurry.

-

Protein extraction. Next, the slurry is processed in an extraction decanter to separate the solubilized protein from the solids, consisting of starch and fibres.

-

Fibre removal. Rotational fibre screens filter the solids, removing fibres from the starch. Wet fibres can then be sent to another decanter for further dewatering before drying, or it may be directed for use in biogas or bioethanol production.

-

Concentration and starch washing. The diluted starch milk is concentrated and transferred to a hydrocyclone starch-washing system. Washing refines the starch milk, which can then be dried into starch powder or used for bioethanol production or syrup production.

-

Protein precipitation. The liquid collected from the extraction step (2) is processed to lower its pH to the protein's isoelectric point, causing the protein to precipitate from the liquid. The precipitated protein slurry then enters a protein decanter, which separates the protein precipitate from the liquid.

-

Protein washing. In the last step, the protein is washed with water to increase its purity. This results in a protein product with higher purity and better organoleptic properties. However, this step may be omitted if a high-purity protein product is not required.

Optimizing plant-based protein processing systems

Leverage Alfa Laval’s expertise in designing plants for the fractionation of agricultural products. Test your feedstocks under actual operating conditions at the Alfa Laval Food & Water Test Centre in Denmark, to determine the optimal system for your processing needs.