FAME biodiesel pretreatment systems

Driven by sustainability concerns, the demand for biofuels from plant and animal fats and oils increases every year. Effective pre-treatment systems are critical for ensuring reliable production of biofuels. Alfa Laval is a leading partner to biofuel producers all around the world, and has decades of experience supporting pre-treatment processes for any type of raw material. We can provide complete lines that include everything necessary for pre-treatment for biodiesel production.

Reliable pre-treatment systems for reliable downstream FAME production

- The market’s most complete supplier of biofuel pre-treatment lines, based on quality, reliable equipment

- Consultation from leading experts, including enzymatic processing, to help you design and optimize your biodiesel pre-treatment process line

- Low energy consumption

- A truly global service network with a comprehensive offering that covers the entire lifecycle of your biodiesel production equipment

- Deep removal of phosphorous and free fatty acids, for the highest biodiesel quality and minimum catalyst consumption

Biodiesel pre-treatment provides the feedstock for a downstream fatty acid methyl ester (FAME) biodiesel unit. FAME catalysts for this transesterification reaction are of the methylate type, which form a catalytically inactive soap in contact with free fatty acids. Minimizing free fatty acids, typically in the range of 0.1-0.2% by weight, is therefore necessary. The pre-treatment process for biodiesel production most often consists of a neutralization section, which for soybean oil can be supplemented by enzymatic degumming, or alternatively, a steam stripper for the physical removal of free fatty acids. Contact us today to learn how we can support your operation.

How it works

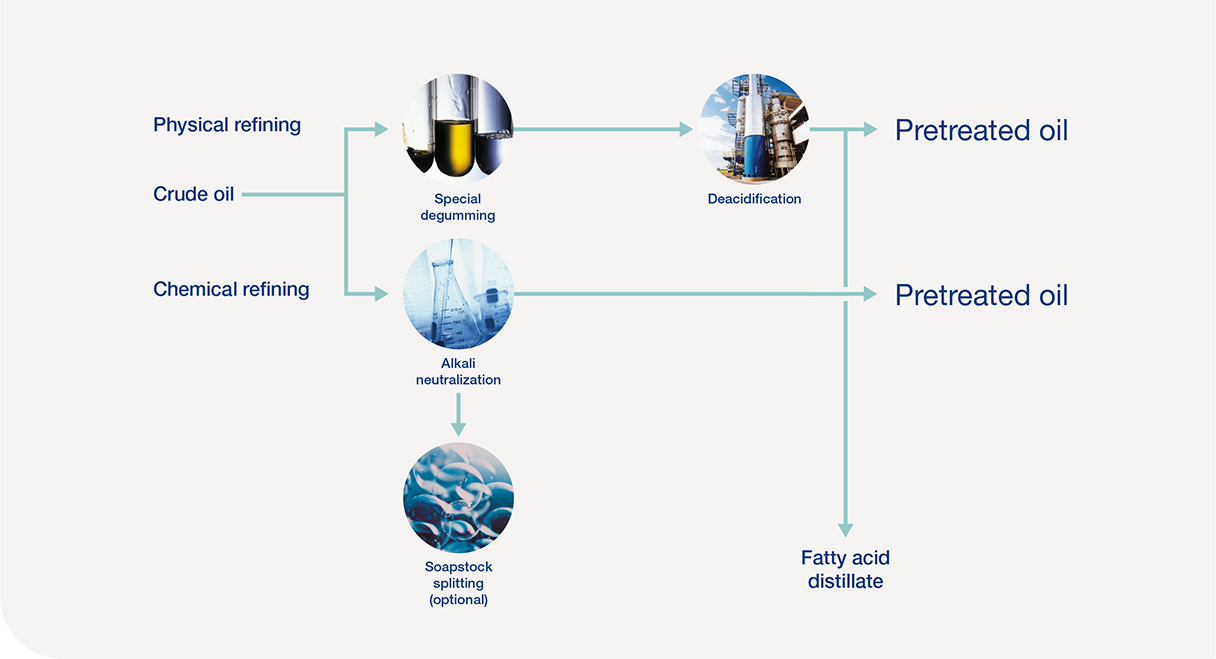

An initial pre-clarification stage may be required to remove fine solids in the oil before it undergoes either a chemical or a physical refining process. In physical refining, compounds containing phosphorous (gums) are removed from the oil in a degumming system, and the feed is thereafter washed to remove phosphorous, soaps and other impurities.

The next step in the pre-treatment process is to remove fatty acids through deacidification, to reach the target content of free fatty acids in the pre-treated oil. Fatty acids are by-products from physical refining, which can either be sold or converted to biodiesel with acid-catalysed esterification (e.g. with sulphuric acid as catalyst).

The use of enzymes, especially when processing soybean oil, has a positive effect on the reduction of the phosphorous content, and also reduces oil losses in pre-treatment, leading to better-quality pre-treated oil and higher yield.

In chemical refining, free fatty acids, phosphorous and other impurities are removed by adding caustic soda which causes soapstock to form. The soapstock is thereafter removed in two high-speed separation steps, the last being a water wash.

Cars don’t need vitamins, people do

Did you know that Alfa Laval offers a solution for extraction of high-value vitamin E and other nutrients from vegetable oils? Alfa Laval TocoBoost is an add-on to our deodorization systems that allows refinery operators to efficiently extract nutrients from soy, palm and other vegetable oils. Don’t let these valuable compounds go to waste and miss out on the opportunity to create new, profitable income streams for your plant. Play the video to learn more.