FAME biodiesel pretreatment systems

As demand for sustainable fuels grows, producers must deliver consistent, high-quality Fatty Acid Methyl Ester (FAME) biodiesel from plant and animal fats and oils. Effective pretreatment removes impurities and ensures reliable feedstock quality for downstream processes. With experience in FAME biodiesel processing lines, Alfa Laval is a trusted partner for biofuel producers worldwide. Our pretreatment lines handle any raw material, enabling safe, clean and optimized FAME biodiesel production.

Optimizing FAME biodiesel production with effective pretreatment

- Maximize uptime and reliability with the comprehensive, premium biofuel pretreatment lines

- Boost process efficiency by leveraging expert guidance to tailored enzymatic processing

- Cut operating costs with energy-efficient pretreatment solutions

- Secure long-term performance through global service and lifecycle support for your systems

- Achieve superior biodiesel quality with optimal removal of phosphorus and free fatty acids while minimizing catalyst use

Alfa Laval biodiesel pretreatment systems condition feedstock for downstream FAME biodiesel production. In transesterification, methylate catalysts can form inactive soaps when exposed to free fatty acids. Reducing free fatty acids (typically 0.1-0.2% by weight) is therefore critical for maximizing efficiency and yield.

Engineered for FAME biodiesel production, Alfa Laval pretreatment processing lines include a neutralization stage, often combined with enzymatic degumming for soybean oil or, if needed for high FFA feedstocks a steam stripper to remove of free fatty acids and phosphorus. The result: cleaner feedstock, high yield, lower catalyst consumption, and more reliable FAME biodiesel production

Contact us to learn how Alfa Laval can support your operations.

How the pretreatment process supports biodiesel production

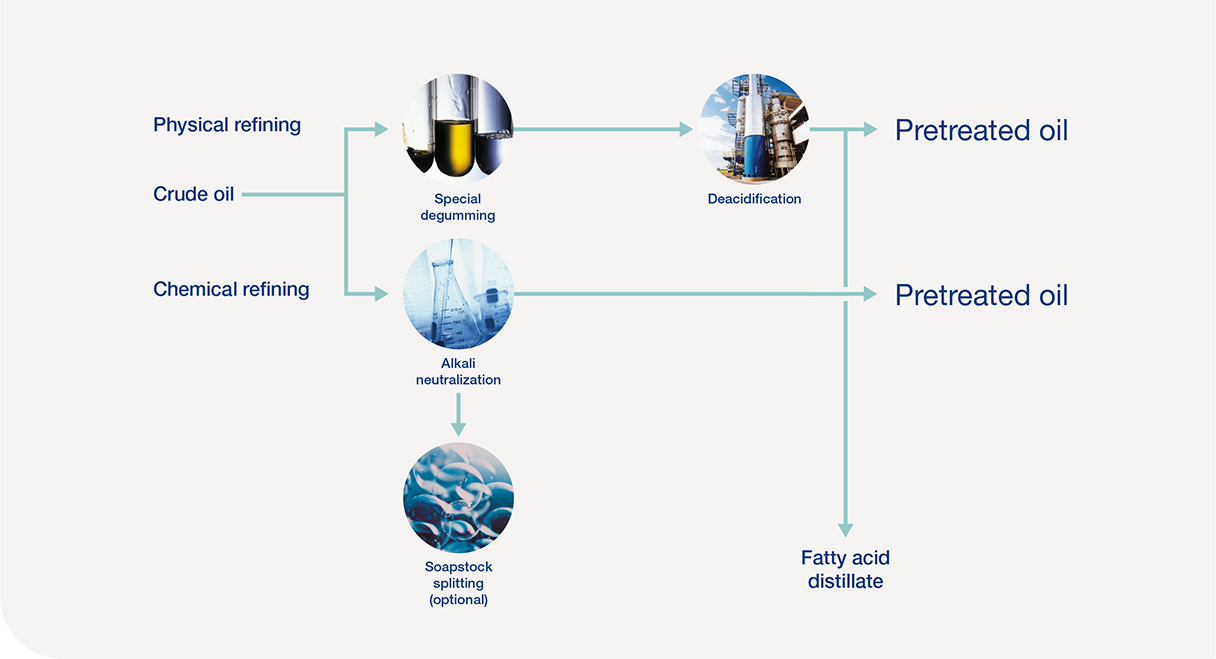

Pretreatment ensures your feedstock meets the quality requirements for efficient biodiesel production. The process often begins with pre-clarification, which removes fine solids from the oil before chemical or a physical refining.

Physical refining removes compounds containing phosphorous (gums) from the oil through degumming, followed by washing to remove phosphorous, soaps and other impurities.

Deacidification then reduces free fatty acids (FFAs) in the pretreated oil to target levels. These FFAs, by-products of physical refining, can be sold or converted into biodiesel through esterification, using sulphuric acid as a catalyst, for example.

Enzymes, especially in soybean oil processing, further reduce phosphorus, minimize oil losses, and increase overall oil quality and yield.

In chemical refining, caustic soda neutralizes FFAs, phosphorus, and other impurities, creating soapstock. The soapstock is then removed in two stages, with the final water wash ensuring lowest possible contaminant levels.

Beyond biodiesel: Unlocking new revenue streams

Alfa Laval offers solutions to extract high-value nutrients, such as vitamin E, from vegetable oils, generating new revenue streams from edible oil refining. The Alfa Laval TocoBoost, for instance, is an add-on to our deodorization systems, enabling refinery owners and operators to extract high-value nutrients from soy, palm and other plant-based oils. Turn by-products into profitable revenue streams.

Watch the video to learn more.

Key products

Key components for biofuel pre-treatment processing

Elevate the performance of your edible oil refining systems

Resource-smart production is essential as edible oils play a critical role in global food security. Optimize your processes over the entire lifecycle of your edible oil systems with the Alfa Laval service portfolio.

Leverage our full range our services - from system design, precision engineering, and effortless installation to commissioning, cost-effective operation, routine maintenance, and system upgrades.

With tailored service agreements, you can reduce waste, safeguard product quality, simplify operations, and maximize your return. Focus on the growth of your business while our global network and local providers take care of the rest.