LKC UltraPure

The Alfa Laval LKC UltraPure Non-return Valve is a hygienic one-way check valve for use in various processes throughout the high-purity industry to prevent reverse flow. It is easy to install, ensuring safety and high product quality.

Non-return valve preventing the reverse flow of fluids

- Highly reliable, self-acting valve

- Easy to install

- Protects process equipment

- Prevents reverse flow

- Full transparency and traceability of the entire supply chain due to the Alfa Laval Q-doc documentation package

The LKC UltraPure Non-return Valve is designed for single directional product flow, meeting the demands of high-purity applications across the biotechnology, pharmaceutical and personal care industries.

UltraPure quality

LKC UltraPure is developed to facilitate safe and easy installation that ensures optimum integrity. This valve offer high and consistent quality and thorough documentation which meet the strict standards of the biotech, pharmaceutical and personal care industries.

High and consistent quality

LKC UltraPure valves are subject to rigorous quality control. Alfa Laval performs all incoming and outgoing quality control and inspections and closely monitors every aspect of the manufacturing process – from raw material sourcing to tolerance and surface finish inspection to packaging and labelling. Tolerances and all surface finishes, for instance, are inspected with calibrated equipment. This helps ensure the highest quality possible.

Completely documented

All equipment and components in the Tri-Clover UltraPure portfolio are supplied with Alfa Laval Q-doc, a comprehensive documentation package that provides full transparency of the entire supply chain, from raw material to final equipment delivery. This smoothes purchasing and installation procedures as well as facilitates qualification, validation and change control procedures. Based on GDP (Good Documentation Practice), Alfa Laval Q-doc covers every aspect of UltraPure equipment supply and provides customers with transparent and well-documented quality assurance of the sourced equipment.

The Q-doc package for LKC UltraPure comprises quality and manufacturing procedures, material certificates and full traceability. This attention to detail maximizes uptime and minimizes risk.

For more information about standards and certificates, please visit our BioPharm Portal.

Product Benefits

- Safe and easy installation

- High and consistent quality

- Completely documented

Find the products you are looking for

The digital Alfa Laval Product Catalogue makes it easy to find and select the products you need. When you request a quote, the catalogue will list Alfa Laval’s partners in your region – and you can send your request directly.

How it works

Application

Tri-Clover® LKC UltraPure is a non-return valve preventing reverse flow in a system. The UltraPure execution is designed and documented to meet the demand in industries like BioPharm and Personal Care.

Working principle

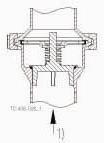

The spring acts on the valve plug and keep the valve closed until the force from the pressure in the inlet exceeds the force of the spring. If a reverse flow should occur the spring force and the pressure from the outlet will keep the valve closed.

Standard Design

The valve body is made in two parts that are assembled with a clamp ring. A guide disc and four legs guide the spring loaded valve plug in the valve body.

1 = Flow direction.

Shows the optimal built-in situation to make sure the valve is drainable. The four guide legs of the valve cone ensures good alignment.

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

- Alfa Laval LKC Non-return Valve

- Alfa Laval LKC UltraPure

- Alfa Laval LKUV-2 Air-relief Valve

- Alfa Laval SB Self-cleaning CO2 Valve

For a broader valve range, explorer the different product categories: ball valves, butterfly valves, diaphragm valves, double seal valves, double seat valves, regulating valves, safety valves, sample valves, shutter valves and single seat valves.

Ten top tips - Valves

Here are some tips and service videos to show how you keep your hygienic valves in tip top condition

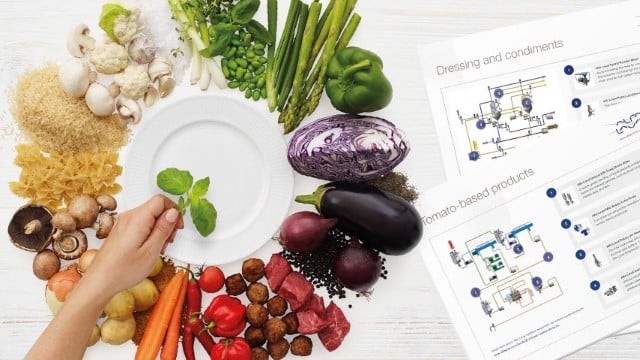

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Close at Hand Catalogue

Alfa Laval's hygienic equipment product catalogue "Close at hand" includes product leaflets, performance curves, links to animations, brochures and lists for ordering purposes.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.