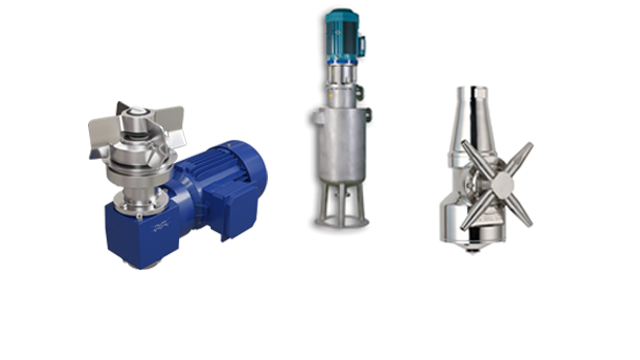

T/TZ

The Alfa Laval T/TZ is a rotary cleaning machine for hygienic environments. Built to clean tanks with various capacities, it combines pressure and flow to create high-impact cleaning jets that rotate in a repeatable and reliable 360-degree cleaning pattern. The TZ cleaner minimizes the consumption of water and cleaning media. Easy to customize to meet customer requirements, it allows companies to spend less time cleaning and more time producing.

Efficient, cost-saving, and safe tank cleaning with 360° coverage

- 60% faster cleaning = more time for production

- Saves up to 70% of your cleaning cost

- Eliminates the need for confined space entry for manual tank cleaning

- High-impact cleaning in a 360° repeatable cleaning pattern

- Cleaning process can be validated using Alfa Laval Rotacheck

The Alfa Laval TZ cleaner is a rotary cleaning machine designed for the removal of the toughest residues from hygienic tanks across a broad range of industries. The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. Due to its design, it is ideal to retrofit spray balls, thereby reducing Cleaning-in-Place (CIP) costs and cleaning time.

.

How does the T/TZ rotary jet heads work?

Dynamic tank cleaning machines

The high-impact jet stream from the four nozzle rotary jet head is preprogrammed to cover the inside of the tank in a successively denser pattern. This provides a powerful mechanical impact, using a low volume of water, acid or caustic. A faster tank cleaning cycle also cuts energy consumption.

The flow of the cleaning fluid makes the nozzles perform a geared rotation around the vertical and horizontal axes. In the first cycle, the nozzles lay out a coarse pattern on the tank surface. Subsequent cycles gradually make the pattern more dense, until a full pattern is reached after eight cycles. This all takes place automatically and provides users with an effective path to quality assurance guarantees in tank cleaning, complete with all the necessary documentation.

Toftejorg rotary jet heads are ideal for cleaning processing, storage and transportation tanks and other vessels used in process, sanitary, pharmaceutical and other industries.

Thorough cost-effective cleaning

To achieve the best possible cleaning results, the Alfa Laval rotary jet heads use an optimized high-impact jet pattern to provide the highest possible coverage. Cleaning patterns reach the inner tank surfaces to ensure the most effective cleaning in place (CIP) solution possible. The jet pressure, or force of impact, efficiently removes residue to provide the hygienic conditions required for batch production. Self-draining and self-cleaning, inside and out, all Toftejorg rotary jet heads devices comply with Good Manufacturing Practice. The Alfa Laval Rotacheck system verifies every cleaning cycle to ensure compliance with today’s strict hygiene standards.

An economic and environmentally correct choice

The Alfa Laval rotary jet heads effectively clean tanks using less water, less energy and less cleaning agents than Static spray ball´s. This not only helps reduce consumption of water and chemicals but boosts your company’s to environmental profile.

Performance reliability and long service life

Rotary jet head technology is proven technology that boosts cleaning efficiency by providing reliable and repeatable cleaning performance. Designed to provide minimal internal pressure loss, the Toftejord tank cleaning machines rotate at pressures around 2-7 bar; however, the recommended operating pressure is between 5 to 6.5 bar, where the optimal and reliable cleaning performance is achieved.

Cleans with concentrated jets and 360° coverage. Highest impact and lowest liquid consumption in shortest time.

High product integrity

To ensure product integrity, all Toftejorg rotary jet head devices are made of safe and non-reactive hygienic materials. All materials made of stainless steel are fully traceable in accordance EC No. 1935/2004. All non-metallic parts used comply with FDA requirements 21CFR § 174; non-metallic parts of rotary jet heads used for the Biopharm applications are certified in accordance with USP Class VI regulations. Upon request, 3.1 certificates can be supplied for those tank cleaning devices that meet the EN10204 standard.

Marine application

Used in the offshore industry and in petrochemicals and chemical processing industries, the T-82 is grease lubricated and designed to clean tanks in a rough environment, e.g. it is widely used in mud tanks on supply vessels and oil rigs where solid particles are in the cleaning media. It is also widely used on barges and product tankers.

The TZ-82 and TZ-75 machines are widely used as portable tank cleaning machines on oil-, product- and chemical tankers.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Part of a broad tank equipment range

Alfa Laval offers a comprehensive range of tank equipment intended for hygienic applications in the dairy, food, beverage, home care, personal care, biotechnology and pharmaceuticals.

For a broader tank equipment range, explore the different product categories: rotary jet heads, rotary spray heads, tank accessories and tank covers.

Rotacheck

Rotacheck is an intelligent sensor that during the CIP process validates the proper function of the Toftejorg rotary jet head.

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.