Cooling the flaming giant

Alfa Laval has installed 12 air coolers at Mittal Steel Ostrava (MSO)in the Czech Republic. The prime reasons for MSO purchasing Alfa Laval equipment were that the air coolers made a perfect fit, and that they save valuable cooling water.

DATE 2025-12-16

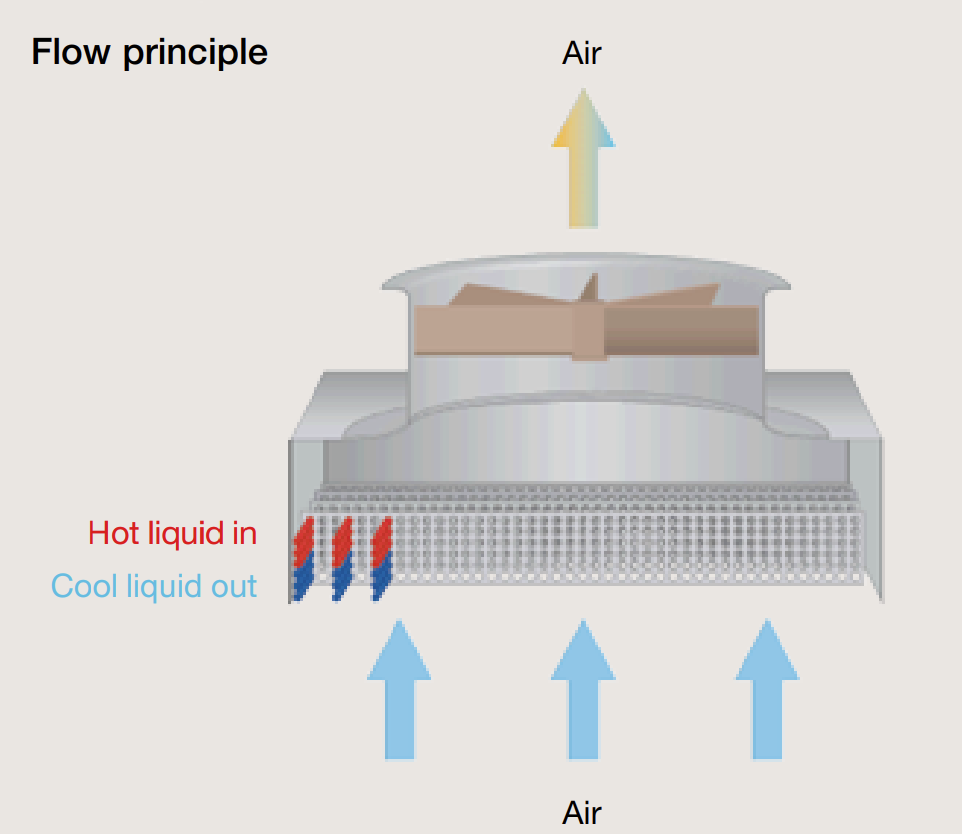

Alfa Laval air coolers have now replaced an open cooling tower water system at Mittal Steel Ostrava

Alfa Laval has installed 12 air coolers at Mittal Steel Ostrava (MSO) in the Czech Republic. The prime reasons for MSO purchasing Alfa Laval equipment were that the air coolers made a perfect fit, and that they save valuable cooling water. This can then be used more effectively in other parts of the process, resulting in greater effective capacity.

Other major benefits include the fact that the circulating water is clean and that the pressure used is optimized to match the specific process. This makes locating any leakages much quicker and easier, so that incidents that might result in unscheduled maintenance work and downtime can be avoided.

Mittal Steel Ostrava (MSO) is the largest integrated steel producer in the Czech Republic and belongs to the world’s largest steel-making company, Arcelor Mittal. In 2006, MSO produced 3.05 million tonnes of steel, featuring flat products, long products, tubes and pipes, and engineering products. The company was established in 1951. It became a state enterprise and was introduced on the Czech stock exchange in 1992. In 2003, it was privatized by the LNM Group and in 2005 renamed Mittal Steel Ostrava.

Vysoke pece Ostrava a.s., previously a subsidiary of MSO, became an MSO plant on 31 December 2006. Plant 12 – Blast Furnaces produces more than 10 000 tonnes of pig iron per day in three blast furnaces that represent the heart of the steel works. A project for reconfiguring the cooling system for two of the blast furnaces was launched in 2002.

Improving the furnace cooling system

Previously, the furnaces were all cooled using an open cooling tower water system. The new objectives were mainly to reduce:

- water consumption

- operating costs for make-up/fresh water and water treatment chemicals

- any risk of fouling, scaling and corrosion

- the repair costs expected for open cooling systems with towers

Plant 12’s choice therefore fell on a closed-loop cooling system. However, the traditional solution using plate heat exchangers was not feasible because there was insufficient fresh cooling water available from sources such as rivers, the sea or cooling tower waters. Plant 12 therefore decided to install a closed-loop cooling system featuring Alfa Laval air coolers for two of the furnaces. “We decided on Alfa Laval because this company had suggested a solution that was the best possible answer to our needs,” says Mr. Hincˇ ica, the Plant 12 facility manager.

The new cooling system was designed for two furnaces, each with a pig iron capacity 2800–3300 tonnes/day, depending on current production levels at the steel works. The system consists of 12 PFC 4H/J8/11/L power fan air coolers – 6 for each furnace. The flow rate for each air cooler is 400 m³/h and water temperature in/out is 54/51°C. Under normal conditions, the heat load is approx. 7000 kW, with up to 10000 kW under extreme conditions during the summer.

The new air coolers were a perfect fit. “The cooling system from Alfa Laval provides us with more advantages than other equipment; we can get good results and are able to keep our costs under tight control. The better the cooling system works, the better our furnaces run,” explains Facility Manager Hincˇ ica. He notes the following among the main benefits that Plant 12 has experienced as a result of installing the Alfa Laval air coolers:

- Improved efficiency

- Reduced water consumption. This water can be used for other furnaces instead, thus cutting down on Plant 12’s overall utilities costs

- The formation of deposits on cooling surfaces, as a result of water chemical treatment, has been done away with • Easy adjustment and control

- Detailed measurements of all the relevant parameters (flow rate, temperature, pressure) are available in each section of the furnaces

- Immediate diagnostics if water leakage or other emergency conditions associated with the furnaces’ cooling elements arise. This makes it much quicker and easier to locate any leakages and helps enable Plant 12 to prevent incidents that might lead to major unscheduled maintenance work, which is extremely costly

Technical features

- Tubes made of copper or stainless steel

- Variable speed control • Wide range of fin spacings

- Explosion-proof (ATEX-compliant) motors

- Combined version (with two liquid circuits) available

- Vertical or horizontal mounting (depending on type)

- Treated to ensure maximum protection and reliability in corrosive environments

Benefits

The new objectives were mainly to reduce:

- water consumption

- operating costs for make-up/fresh water and water treatment chemicals

- any risk of fouling, scaling and corrosion

- the repair costs expected for open cooling systems with towers.