CHNX decanter improves tar recovery in Belgium

ArcelorMittal Gent, Belgium

DATE 2025-12-17In 2004, Belgium’s ArcelorMittal Gent steel plant decided to replace a two-phase decanter for separation of coal tar in the tar recovery plant. For this difficult duty, involving erosive fluids, the company chose an Alfa Laval CHNX 418. Kenneth Vermaut, Production Manager, explains that the sealing on the casing was a critical factor since the aim was to minimise leakage.

By reducing leakage, we have decreased the need for cleaning and reduced downtime. The decanter has also made the process cleaner and safer.”

ArcelorMittal Gent (previously known as Sidmar) is a maritime and integrated steel producer with an annual output of nearly five million tons of crude steel. The plant also has a hot strip and cold rolling mill, with annual outputs of about 4,4 and 2,9 million tonnes, respectively. Located on the Ghent-Terneuzen channel, some 20 km from Ghent, ArcelorMittal Gent is the largest private employer in the Belgian province of East Flanders, employing about 5,600 people.

Belgium’s ArcelorMittal Gent steel plant has installed a CHNX 418 decanter from Alfa Laval for separation of coal tar in the tar recovery plant.

New investment in coal tar recovery

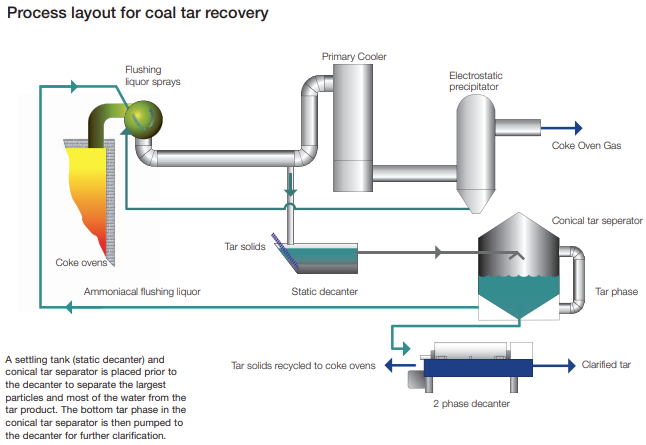

In September 2004 Sidmar replaced an old tar decanter with an Alfa Laval CHNX 418 two-phase decanter for coal tar recovery. Prior to the decanter there are 3 static decanters to remove larger solid particles. After the static decanter there is a conical tar separator to separate the water and the tar. The bottom tar phase of the tar separator is then pumped to the decanter for further clarification.

Kenneth Vermaut, Production Manager at the coking plant, relates that the main criteria in his choice of supplier were price, quality, and the type of sealing on the casing of the decanter.

‘We chose quality from the start’

Coal tar separation is a difficult duty due to the erosive fluids involved, and decanters normally require a few days of installation and fine tuning to the process before working according to the specification. The problem was that we could not run without a tar decanter for more than 8 hours, so the startup needed to be fast. Therefore, we decided at an early stage to go for a high-quality product from a reputable supplier. Alfa Laval is known for its high performance and service to customers.”

Kenneth Vermaut already has experience of Alfa Laval as a supplier with Alfa Laval equipment in service in various areas of the coke plant. There are 20 spiral heat exchangers installed in the desulphurisation plant, for example.

Reduced downtime, increased safety

In this project, our aim was to minimise leakage from the machine and increase overall safety in the plant. Therefore the type of sealing was critical. By reducing leakage we have also reduced the need for cleaning and, in turn, downtime. In addition, after installing the decanter the amount of QI:s in the tar product has been reduced from 2 to less than 1.5%, producing an end product with fewer solids and better processability.”

- Kenneth Vermaut

Mr Vermaut adds that the project was entirely successful:

In the beginning there were some problems with vibration and the lifetime of the sealing elements. However, Alfa Laval worked closely with us to solve these and today the coal tar decanter is giving us problem-free running. All-in-all, we are very satisfied."

Alfa Laval CHNX 418 two-phase decanter installed at ArcelorMittal Gent for coal tar recovery.

Products

The STNX range of high-performance decanter centrifuges provides the starch industry with the most cost-effective separation solution available, with the lowest power consumption and life cycle costs as well as the most advanced technology.

Customer's voice

By reducing leakage we have decreased the need for cleaning and reduced downtime. The decanter has also made the process cleaner and safer.

Kenneth Vermaut