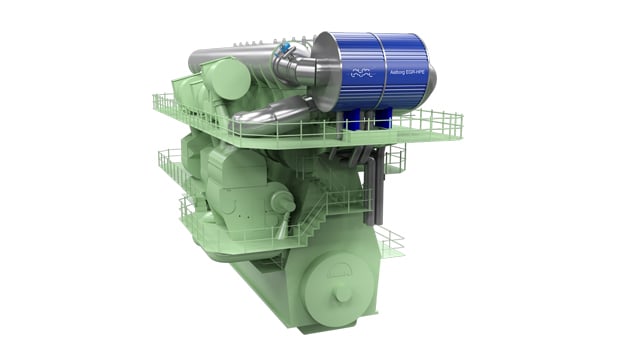

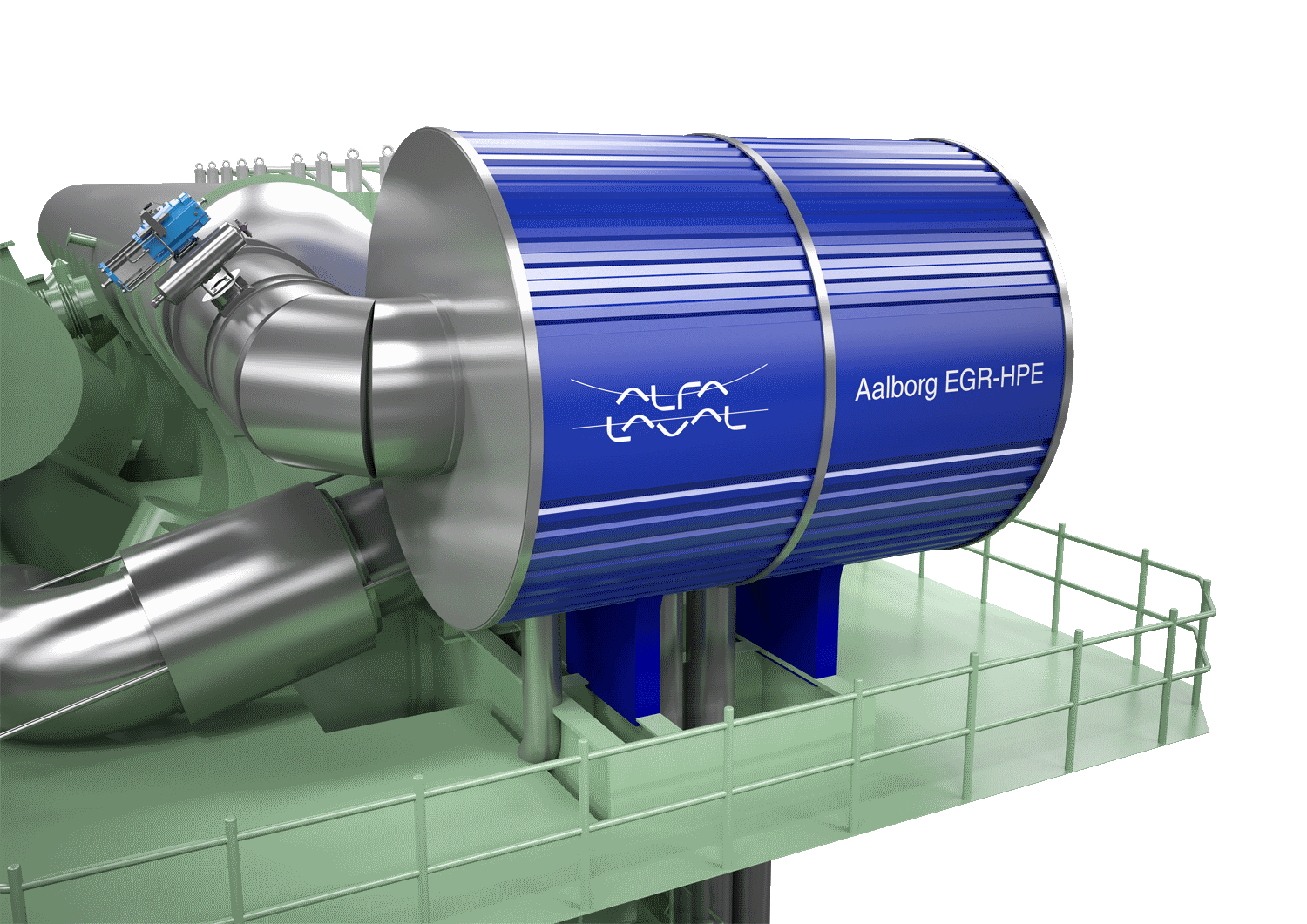

Added to EGR, the Alfa Laval Aalborg EGR-HPE economizer can turn compliance into profit

With Tier III NOx limits entering into force in North America and the US Caribbean in January 2016, the time has come for many ship owners to choose their method of compliance. Exhaust Gas Recirculation (EGR) on MAN B&W engines has strong advantages on its own. But combined with a new pressurized EGR economizer from Alfa Laval, it also offers the potential for massive fuel savings.

DATE 2023-11-28“EGR provides Tier III NOx compliance with a very compact footprint, but compliance itself is only part of the full potential,” says John Pedersen, Business Manager, Marine Systems at Alfa Laval. “Working closely with MAN Diesel & Turbo to optimize the EGR technology, we saw additional opportunities through our expertise in marine boilers. The result is the Alfa Laval Aalborg EGR-HPE economizer, which paves the way for extraordinary energy and fuel savings.”

“EGR provides Tier III NOx compliance with a very compact footprint, but compliance itself is only part of the full potential,” says John Pedersen, Business Manager, Marine Systems at Alfa Laval. “Working closely with MAN Diesel & Turbo to optimize the EGR technology, we saw additional opportunities through our expertise in marine boilers. The result is the Alfa Laval Aalborg EGR-HPE economizer, which paves the way for extraordinary energy and fuel savings.”

Developed by Alfa Laval in close cooperation with MAN Diesel & Turbo, the Aalborg EGR-HPE is a revolutionary new economizer enclosed in a pressure casing. Placed in-line ahead of the pre-scrubber sprayers in the EGR circuit, it can be used for a number of advantages. If connected to a conventional waste heat recovery system, for example, waste heat recovery becomes substantially more efficient – and is possible at significantly lower engine loads.

Developed by Alfa Laval in close cooperation with MAN Diesel & Turbo, the Aalborg EGR-HPE is a revolutionary new economizer enclosed in a pressure casing. Placed in-line ahead of the pre-scrubber sprayers in the EGR circuit, it can be used for a number of advantages. If connected to a conventional waste heat recovery system, for example, waste heat recovery becomes substantially more efficient – and is possible at significantly lower engine loads.

“By moving the break point for waste heat recovery from a medium engine load down to a low load, the Aalborg EGR-HPE enables even slower steaming,” says Pedersen. “That means fuel savings that quickly pay back the boiler, offset the EGR investment and lower CO2 emissions on top of the NOx reduction.”

Taking advantage of diverted heat

The source of all these benefits is the heat that would otherwise be lost during EGR. In the EGR process, around 30% of the exhaust gas is directed back into the engine, which reduces the combustion temperature and thereby the production of NOx. Since only the remaining 70% of the gas reaches the traditional exhaust gas boiler after the turbocharger, waste heat recovery is reduced by 30% as well.

By installing the Aalborg EGR-HPE, that loss is turned into a gain. Placed in-line before the EGR pre-scrubber spray jets that cool the exhaust gas, the boiler has access to much higher temperatures than traditional exhaust gas boilers. So while the installation is light, compact and self-cleaning due to the high speed of flow, its application potential is enormous. This can be seen in the way it increases the efficiency of a conventional waste heat recovery system.

More power from the steam turbine

The Aalborg EGR-HPE is integrated with conventional waste heat recovery after the turbocharger by means of its steam drum, which is shared by the traditional exhaust gas boiler. With the output of the traditional economizer feeding into the shared drum, the Aalborg EGR-HPE produces extremely high-quality steam with a temperature of just above 400°C, bringing the waste heat recovery system to a much higher level of efficiency.

“The difference in steam quality has a direct effect on the performance of the steam turbine,” says Pedersen. “Installation factors play a role, but a substantial increase in power generation can be expected.”

Fuel savings through even slower steaming

Even more importantly, using the Aalborg EGR-HPE in an integrated system allows waste heat recovery to occur at lower main engine loads than would be possible with a traditional waste heat recovery system in Tier III operation. In other words, it creates the possibility of even slower steaming.

“The EGR economizer makes waste heat recovery beneficial at far lower engine loads, down to around 30%” says Pedersen. “This means that vessels can steam even slower, with huge fuel savings as a result. A vessel performing EGR and using the Aalborg EGR-HPE will be not only compliant with Tier III, but also substantially more fuel efficient.”

Proven results at sea

The savings with the Aalborg EGR-HPE are anything but theoretical. In a project supported by the Danish Energy-Technological Development and Demonstration Programme (EUDP) and developed in cooperation with Aalborg University, the EGR boiler has been rigorously tested aboard the Maersk Cardiff, a container newbuild from A.P. Moller-Maersk.

“As a front-runner in the pursuit of green technologies, we were keen to see what the Aalborg EGR-HPE could do,” says Ole Christensen, Senior Machinery Specialist at A.P. Moller-Maersk. “But while we were enthusiastic about the boiler’s potential, we were also somewhat uncertain as how it would handle the physical realities of EGR. The temperatures are twice as high as those of traditional waste heat recovery, and the gas pressures are far greater.”

Those concerns were quickly dissipated when the boiler was brought online with the Maersk Cardiff’s two-stroke MAN B&W 6S80ME-C9 engine in November 2014. “Not only did the boiler survive,” says Christensen, “the results we have seen during testing are very promising.”

Completing the EGR offering

For those still debating their choice of Tier III NOx compliance, the Aalborg EGR-HPE may well influence the final decision.

“By introducing the EGR boiler into the NOx equation, we’ve truly changed the balance,” says Alfa Laval’s Pedersen. “Suddenly EGR is not only a means of Tier III compliance, but also a means of radically improving the vessel’s energy efficiency. And that makes it a very different sort of investment.”