Maximizing cooling and heat reuse: How AlfaQ heat exchangers are revolutionizing the way we connect data centers to district heating

HeatChain is an energy-tech company that specializes in the recovery and utilization of excess heat from data centers and other industrial processes. Their core idea is simple but powerful: data centers generate a constant stream of excess heat, and the right technology can capture this energy for district heating.

DATE 2026-02-06To turn this vision into a reality, HeatChain designs, builds, and operates modular, premanufactured data heating plants or ‘data boilers’ where IT companies own and manage the servers themselves, while HeatChain provides the full supporting infra - structure for seamless high-performance computing (HPC) and waste-heat recovery. Today, HeatChain stands out as one of the pioneering companies in Finland already delivering recovered data center heat to local district heating networks in Finland, utilizing advanced Alfa Laval AlfaQ heat exchangers.

Maintaining high temperatures with minimal energy loss - the key to efficient waste-heat recovery

Transferring waste heat from a typical data center to district heating networks is rarely straightforward. In most cases, the low-grade heat (often 25–50 °C) requires energy-intensive heat pumps to boost temperatures to the 70–90+ °C needed for an effective district heating supply.

HeatChain takes a smarter approach. By utilising their advanced liquid cooling technology and HPC computers as the heat source, they can deliver significantly higher-grade waste heat and maintain an optimal 75–80 °C temperature. In other words, HeatChain’s system is the ideal temperature for direct heat transfer to local district heating networks and provides energy efficient server cooling at the same time. The best part is that it consumes substantially less energy and is much more cost efficient than the conventional solutions that rely on heat pumps.

To transfer this high-grade heat to district heating networks with minimal temperature degradation, the system is engineered to operate with a very small logarithmic mean temperature difference (LMTD) in the heat exchangers. This approach maximizes thermal efficiency, preserves valuable heat quality close to the source temperature, and allows HeatChain’s modular data boilers to deliver reliable, low-loss heat supply.

Partnership and trust pave the way

When it came to choosing the right heat transfer partner, HeatChain were looking for superior product performance as well as strong collaboration and expert support. The balance between cost and quality needed to be right, and thanks to their strong relationship with Afa Laval technical sales, HeatChain could rely on us to get the job done.

An AHRI certified solution for highly efficient heat transfer

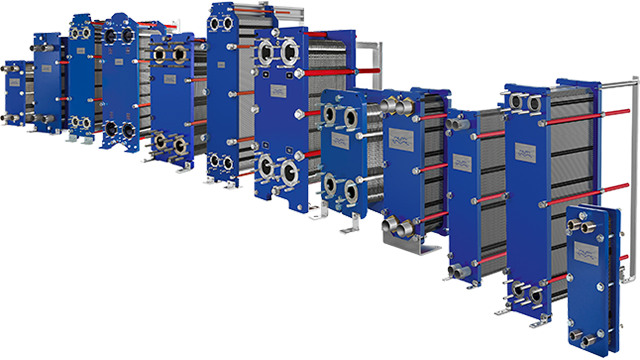

They have three main sizes for the units in their modular data boilers (1 MW, 2 MW and 5 MW units), and Alfa Laval was able to supply standardised solutions for all. This made planning and implementation straightforward, making sure they were up and running in no time. And, since all the heat exchangers are AHRI certified, HeatChain knew that they didn’t have to just take our word for it. They had a solution that could walk the talk.

Alfa Laval is a well-known and trusted partner for HeatChain. The heat exchangers aren’t just impressive on paper—they deliver reliable per - formance in real life, which is crucial for minimizing energy losses. “ says Petteri Hajanti, CEO.

Alfa Laval has delivered two kinds of AlfaQ heat exchangers to 10 HeatChain data centers across Finland so far, with larger standard sized heat exchangers on the way. The selected heat exchangers operate in pairs, with one in place for backup cooling.

These small, modular, and fully prefabricated facilities can be set up quickly, with new facilities historically going live roughly every 2 months. And, thanks to the support of AlfaQ plate heat exchanger, we can make sure no possibility to utilize data center excess heat in district heating is wasted.

Petteri Hajanti, CEO, HeatChain

Walking the talk

As they operate the data boiler facilities themselves, HeatChain has been able to collect lots of measured data from the process in real time and corroborate the success of the project. We are thrilled to announces that the AlfaQ results matched the performance we promise on paper.

In 2025 HeatChain owned or operated data boiler facilities delivered 50 GWh clean district heating energy with the support of Alfa Laval heat transfer technology. That’s a significant achievement, considering how new and fast the technology is. In addition, these facilities achieved 3,650 tons of CO₂ emission reductions in district heating production, with an impressive average annualized PUE of 1.04 and an annualized Energy Reuse Factor (ERF) of 64%, demonstrating both high energy efficiency and substantial environmental benefits. More results in the link.

Why data center heat reuse is so in demand

As the world continues to embrace digitalisation and AI, the new capacity demands need a home. The real challenge isn’t just about adding more servers, it’s about building sustainable infrastructure to support them. One innovative solution is heat reuse from data centers.

By collaborating with companies like HeatChain, IT firms can channel the excess heat generated by their data centers directly into local district heating networks. The best part is that it is mutually beneficial. IT companies get the crucial support they need to manage data center cooling, while district heating providers gain a reliable source of high-quality heat.

Download the story

About HeatChain

HeatChain is an energy-tech company that designs, builds, and operates modular ‘data boilers’ along with industrial-scale electric boiler systems. They also deliver customized liquid-cooling solutions that can be tailored to even the most demanding AI and HPC workloads.

HeatChain partners with data center operators, energy companies, and cities to provide high-performance AI and HPC computing, while also capturing and repurposing data center waste heat into clean, carbon-free district heating.