Veramaris’s algae oil revolution boosted by Alfa Laval’s evaporation technology

One of the world’s leading producers of next generation alternative feed ingredients for aquaculture has turned to Alfa Laval technology to harness the power of natural marine microalgae and deliver a product that helps to reshape how the world is nourished with Omega-3.

DATE 2025-12-01

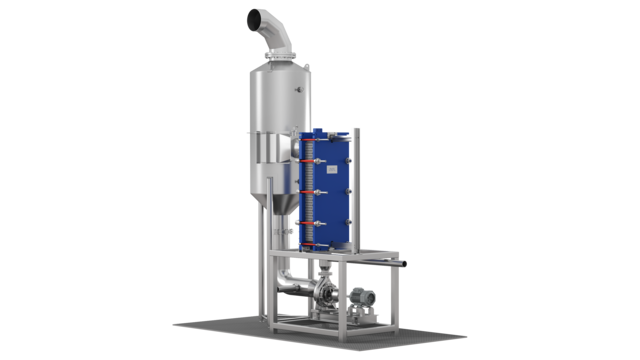

The AlfaFlash evaporation system with MVR (Mechanical Vapour Recompression) technology is a key part of the production line at Veramaris’s facility in Blair, Nebraska, in the USA, which produces Omega-3 EPA and DHA from natural marine algae. Whilst fish oil has traditionally been used as a primary source of Omega-3 in aquaculture diets, there just isn’t enough to support the growth of aquaculture, so Veramaris is helping the industry to grow sustainably with their certified, science-driven supplement that supports animal health and empowers seafood farmers to fully control the nutrition of their farmed fish and shrimp.

Algea oil is produced by precision fermenting of the microalgae to yield a nutrient-rich product that is 65% Omega-3 EPA and DHA fatty acids – making it four times richer than traditional fish oil and well suited as a feed ingredient.

The microalgae is mixed with water and nutrients in the lab fermenter and continues to grow as a broth before it arrives at the production fermenter, where cultivation is completed and the algal oil is harvested. The resulting product is the world’s first ASC-MSC-certified microalgae oil for fish and shrimp feed.

When Veramaris began planning the novel facility, they worked with Alfa Laval to ensure that energy efficiency in the evaporation phase was optimized alongside an overall lowering of CO2 emissions.

By providing an alternative, scalable source of Omega-3, we’re helping the industry achieve sustainable growth.

Gertjan de Koning, CEO at Veramaris

“This was a totally new process for the team at Veramaris, so at the outset, we ran tests with the product at our test facility in Denmark,” explains Anders Gidner, Head of Evaporations Systems at Alfa Laval. “They decided early on to optimize energy efficiency by running the evaporator with MVR (mechanical vapour recompression) using electricity from 100% renewable sources such as wind or solar power.” The MVR greatly reduces the need for natural gas demand from steam-generating boilers.

The testing process also enabled Alfa Laval to demonstrate how the AlfaFlash evaporation system is designed to maximize uptime and optimize intervals between CIP (cleaning in place). The volume of water and chemicals required during cleaning is reduced due to the smaller hold-up volume compared to tubular evaporators, and this compact design has the additional benefit of lowering the steel requirement for equipment and support structures by approximately 50%.

All of these factors contributed to Veramaris’s reduction of their absolute GHG emissions by 5.6% versus 2021 baseline, even as Veramaris scaled up: increasing their production by 61%.

This innovative approach is set to have a growing impact as more than half of the global seafood production to help feed the world’s growing population already comes from aquaculture. The adoption of algae oil as a feed ingredient supports growth of healthy seafood supply, without increasing the pressure on wild-caught fish for feed.

Highlighted Technologies

Even as Veramaris scaled up, increasing their production by 61%, they reduced their absolute GHG emissions by 5.6% versus their 2021 baseline.