Sludge treatment

Alfa Laval supplies wastewater treatment equipment that cover the entire sludge treatment process, including sludge dewatering, sludge thickening, heating, cooling, heat recovery, digestion and pasteurization, as well as advanced control systems for optimizing dewatering and reducing manpower requirements, whilst reducing sewage disposal costs by effectively decreasing the liquid content of sludge.

Benefits of our circular economy solutions for sludge treatment

- Reduce the waste disposal amount by up to 90%, saving transportation, effluent disposal, storage and drying costs

- New income streams from recovered resources

- Reduce environmental impacts

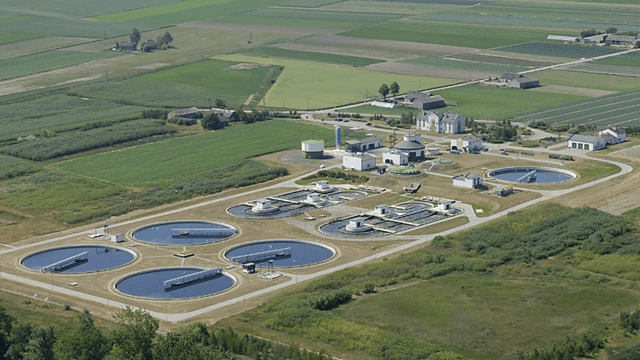

On-site sludge thickening and sludge dewatering is a fundamental part of all current wastewater treatment processes to reduce sludge volume, waste disposal cost and meet sustainability requirements. It is also highly relevant for sludge to be used as digester feed for biogas production, thermal processes and composting. To meet every need, Alfa Laval offers robust, well-proven technologies that effectively separate off the liquid phases and achieve a high level of dry solids content.

Sludge Thickening Methods

In primary or secondary treatment of wastewater, mechanical sludge thickening of sludge from clarifiers has become the industry norm prior to digestion or dewatering.

Alfa Laval’s sludge thickening machines all have enclosed designs plus very low maintenance and odour control requirements:

Gravity belt thickeners

Flocculation sludge thickening, suitable for all municipal or industrial flocculated sludges AS-H Belt Thickeners are integrated with polymer mixing for small to medium capacity.

Decanter centrifuges

Aldec, Aldec G3 or Aldec G3 VecFlow sludge decanters for high performance centrifugal separation and sludge thickening and dewatering with high cake dryness.

Sludge Dewatering Methods

For efficient sludge dewatering and separation of liquid and products from other waste streams you can choose between several Alfa Laval technologies, depending on the level of dry solids content desired, space available and other requirements:

Belt presses

AS-H belt presses for high volume and solids loading with low polymer and power use.

Filter presses

AS-H plate presses for smaller batches where very high dry cake solids (up to 40%) and solids capture over 99% is required.

Decanter centrifuges

ALDEC G3 and ALDEC G3 VecFlow for very high capacities with very small footprint and low energy consumption. It has up to 5x capacity on the same footprint as a conventional belt press. These are Alfa Laval’s latest generation of sludge dewatering equipment for municipal and industrial wastewater treatment.

Some of these can also be used for mud dewatering, mine tailings, pond clean-up and dredging.

Introducing the new Alfa Laval Aldec G3 VecFlow™

Get unmatched efficiency for dewatering and thickening of wastewater sludge.

Thermal sludge treatment

A short cut to cost saving, heat recovery, Class A compost and biogas

Pre-heating of wastewater sludge using Alfa Laval spiral heat exchangers prior to sludge dewatering can also cut costs and provide an opportunity for heat recovery.

Our thermal equipment can also be used for sludge digestion to produce biogas and for sludge hydrolysis and pasteurization to meet even the most stringent environmental legislation and obtain class A or B sludge quality suitable for reuse as compost or fertilizer.

For some types of industrial waste, e.g. pharmaceutical, pasteurization of wastewater sludge is a must. Spiral heat exchangers can also be used for final effluent cooling to recover heat and, if it is to be discharged into the sea, river or stream, to protect the biology of the water body.

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

Service

Extending the performance of your wastewater treatment equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Please contact us with any queries or questions.

Performance audit for Decanter Centrifuges

Get decanter centrifuge optimization and cost-savings throughout the sludge thickening and dewatering process with Alfa Laval Performance Audit as our global service and support experts help make the most out of your equipment.

Minimize operating cost with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services aiming to reduce operating costs and maximize operating reliability in wastewater plants. Our Connectivity Solutions taking advantages of Industrial Internet of Things (IIoTs) technologies help us serve you better in domains such as predictive preventive maintenance, remote control, optimisation and more.