Industrial fluids management: from operations to environment

Alfa Laval centrifugal disc stack separators are extremely efficient in removing fine solid particles and liquid contaminants from different kinds of utility fluids. Investing in a separator from Alfa Laval for cleaning your contaminated fluids, secures an outstanding three phase separation of water, oil, and particulates in one continuous operation. This allows you to reduce your operating costs and create a healthier working environment. As original inventors of the disc stack centrifuge, Alfa Laval’s 130 years of experience ensures we not only have the knowhow to deliver the best equipment to meet your needs, but also the latest advances in separation technology making your operations environmentally sound and intrinsically safer.

Explore our product selection for cleaning water-based industrial fluids

Explore our product selection for cleaning oil-based industrial fluids

Water-based industrial fluids in metal working industries

Coolants

Water-based coolants, or coolant emulsion, are typically used in metal working industries and its operation. Important factors for the lifetime of the liquid and tool quality is to keep them clean. Alfa Laval have a range of separators that effectively recycle coolants by cleaning both tramp oil and smaller particles from the fluid.

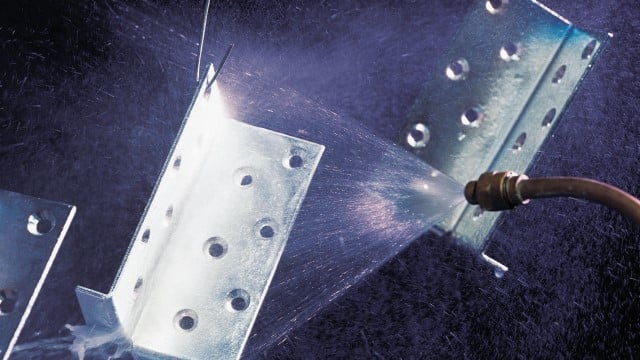

Cutting fluids

Alfa Laval supplies a broad range of fluid cleaning solutions for the metalworking industry. All metalworking processes, from cutting to forming, benefit from efficient cleaning of the service fluid. Consistent quality of the fluid is essential for end-product quality.

Wash liquids

Replacing wash fluids is expensive due to ever increasing disposal costs and production downtime. Efficient separation of harmful components from the wash fluid reduces disposal cost, provides higher quality end-products, better work environment and more sustainable production.

Oil-based utility fluids in machinery and manufacturing

Lube and mineral oil

The quality of lubricants such as mineral and synthetic oils, determines equipment lifetime and level of productivity. Clean lube oil maintains its quality over time and is essential to a healthy, trouble-free process. We offer many options for cleaning lube oil from water and particles in order to prolong oil lifetime.

Cutting oil

High quality cutting oil emulsion improves performance and extends tools lifetime in many cutting and drilling operations. With a disc stack separator from Alfa Laval, you can efficiently recycle your cutting oil and reduce replacement costs, by cleaning the fluids from liquid and particle contaminants in one single operation.

Hydraulic oil

The lifetime of the oil is dependent on conditions like temperature, particles and water content. If the oil remains clean, operation runs according to plan. We offer a range of separators to efficiently clean the hydraulic fluids from particles and water contamination, keeping production costs low whilst maintaining the oils valuable properties.

Separator service kits and spare parts

An Alfa Laval centrifugal separator will perform for decades if you look after it properly. We offer high-quality separator service kits and durable parts, designed to simplify maintenance, boost productivity and maximize uptime. Our service kits include what is required for every specific service as described in your manual, with genuine spare parts and a comprehensive package of detailed service instructions. Explore our service offering for our industrial fluids cleaning separators and visit our webshop to order your kit today!

Visit webshop

The Alfa Laval webshop help you to filter, select and quote the best solution for effective cleaning of coolants, wash liquids and lube oil. Enter the online catalogue and find your selected products and parts now. If the products are not visible for your country, please fill out the contact form.

Get in touch to find out what is best for you!

Centrifuges easily outperform other technologies for cleaning industrial fluids. The investment depends heavily on your process and demands. Let our expertise guide you to the right technology for your operation.