Next-generation food

Alfa Laval works across all food industries and collaborates with customers to confidently introduce new food production processes to meet the requirement for the minimized environmental impact of future food processing

Our range of food-grade solutions enables both established food producers and start-ups to secure compliance with food safety regulations and introduce profitable new food products to market.

Next-generation food covers a range of food produced in different ways. Cultured meat as well as fermentation-derived foods, and new kinds of plant-based protein and food ingredients, are the focal points in Alfa Laval’s engagement in the field of next-gen food.

From Farm to Fork - or?

A significant aspect of the value chain for next-generation food is that the the role of the agricultural sector is either drastically reduced or completely taken out of the equation:

The big food transformation

The development of food production is marked by concerns over the impact on emissions, land-use, water-withdrawal and biodiversity.

Today, the agricultural sector consumes 70 percent of all withdrawn freshwater, while world food production accounts for almost a third of all greenhouse gas emissions. The agricultural sector is also believed to have the biggest impact on biodiversity, land degradation, freshwater resources and deforestation globally.

In less than a generation, we must produce up to 70 percent more food for a growing population – and not just any food. Demand is increasing for healthier and more nutritious food. And it must be produced with a reduced impact on the environment.

This is a dual challenge: we must reduce emissions to reverse global warming, while adapting to climate changes by optimizing the water footprint of food production and protecting land, water, soil and biodiversity.

This is the Big Food Transformation.

Cultured meat

Meat can be grown from animal cells. At the cellular level, this kind of meat is identical to conventionally produced meat. This is what is commonly known as cultured meat. Compared to conventional meat production, the process of growing cultured meat has a substantially smaller environmental footprint. It requires much less land and water and emits up to 90 percent less greenhouse gases (UN, 2019).

From a food safety perspective, cultured meat is the preferred choice. It will drastically reduce the risk of diseases being transmitted from animals to humans. Today, this comprises a large percentage of new and existing diseases in humans (WHO, 2020).

Cultured meat will likewise reduce the risks of drug and pesticide residues and microbial contamination of food. These can have acute or chronic health effects, while also leading to e.g., a resistance to the effects of antibiotics in the treatment of life-threatening diseases (WHO, 2022).

Fermentation-derived protein and food ingredients

Fermentation processes are rooted in ancient culinary traditions.

New ways of applying biomass and precision fermentation processes are key to radically changing the environmental impact of food production.

With biomass and precision fermentation, we can fill a widening gap in protein supplies by cultivating and harvesting proteins and other ingredients, which can be used to enrich a variety of food and beverage products.

Compared to conventional foods and ingredients, precision fermentation enables a reduction of GHG emissions and water consumption by approximately 90 percent (UNEP, 2023).

Plant-based protein

Giving preference to plant-based protein is a well-established measure to improve the environmental impact of an individual’s diet. The annual GHG footprint can improve by as much as 2.1 tonnes annually per person (UN, 2019).

Considering the future demand for food and the limitations of available and suitable farmland and freshwater, producing food and ingredients from plant-based raw materials play a critical role in the future food landscape. However, we also know that there is insufficient farmland for this to be a stand-alone solution.

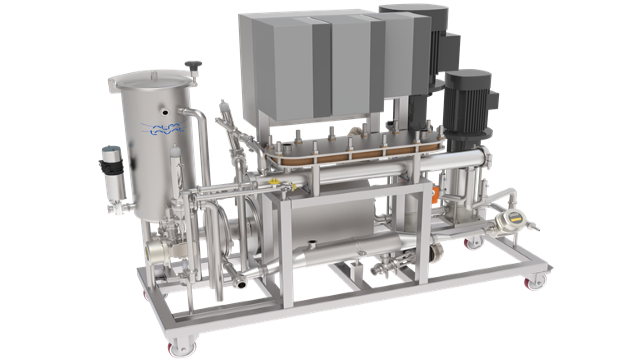

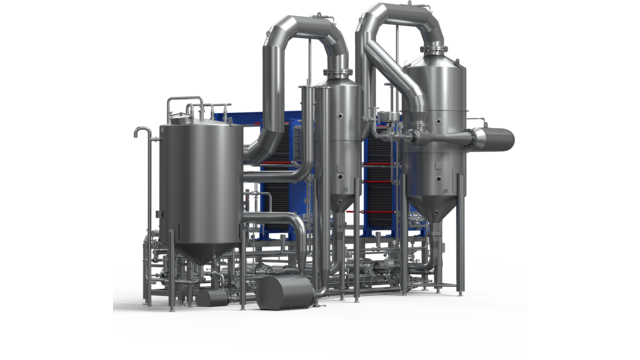

Here for the beer: upcycling sustainable protein from brewer’s spent grain

Sustainable sources of high-quality protein are essential in meeting the ever-increasing global demand for healthy, affordable, and nutritious food. Alfa Laval’s expertise within protein makes it an ideal technology and solutions partner in this field.

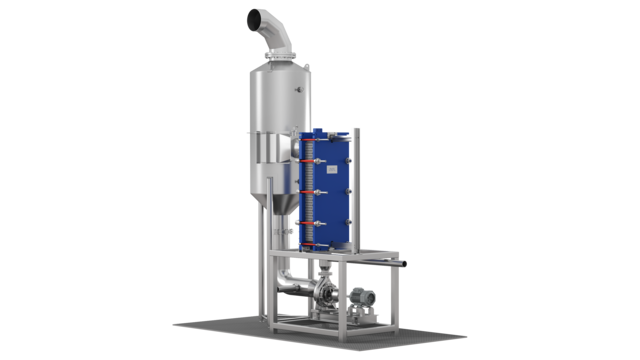

Introducing a new heat treatment technology for oat beverage

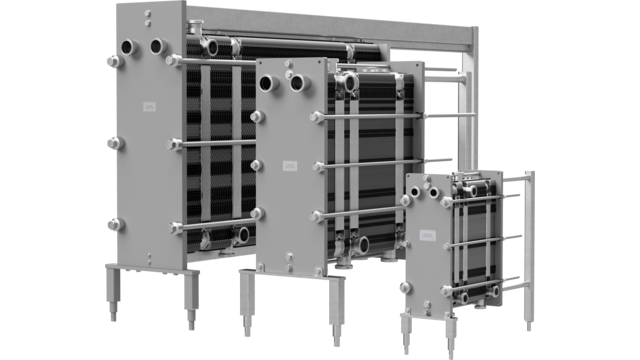

When a liquid food producer in northern Europe was looking to replace an existing heat exchanger which they used for heating up oat-base, they deviated from the conventional path by not choosing a shell & tube solution. Instead, they chose an HL8-WG from Alfa Laval’s Hygienic line.

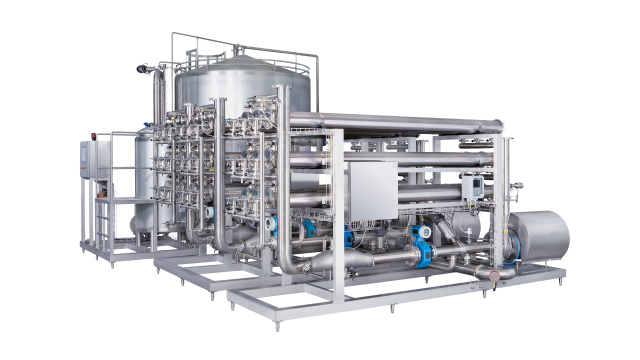

Setting the standard for water recovery and circular reuse in oat drink production

As plant-based drinks producers look to increase production in a global market predicted to rise to USD 71.46 billion by 2030 (Facts & Figures Research, 2023), innovative leaders in the industry are incorporating ‘sustainability as standard’ and building circularity into their expanding operations.