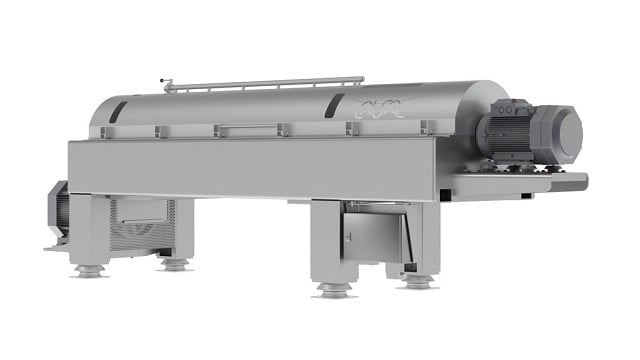

Foodec

Alfa Laval Foodec decanter centrifuges are ideal for industries where delicate food and beverage products are processed – and where easy cleaning is crucial. The Foodec decanter centrifuges for food processing are specially designed for use in food and beverage processing applications. In industrial food processing, hygiene standards are particularly important in order to comply with strict sanitary regulations.

Benefits of using Foodec decanter centrifuge for beverage and food processing

- Higher extraction yield, drier cake and clearer liquid

- Minimize separation costs while delivering a high quality end product

- Easy and fast cleaning with CIP thanks to AL cleaning technology and innovative control system software

- High operational flexibility to adapt to different processes or raw materials

- The drive system offers much lower power consumption than alternative technologies

Foodec decanters are ideal for use in food industry applications in which the material being processed has to be separated into a liquid and a solid phase.

Foodec units are available with two-phase gravity liquid discharge or with pressurized liquid discharge (paring disc). Foodec decanter centrifuges for food processing deliver a high extraction yield and a very low solids content in the liquid.

For uses where levels of cleanability has a higher demand, the special Foodec Hygiene Plus units are available, with additional features that make cleaning easier, faster and even more straightforward. Foodec decanter centrifuges feature a consistent focus on reliability, cleanability, continuous operation and easy maintenance. Ideal for industrial food and beverage processing.

Case Stories - Using Alfa Laval´s decanter centrifuges in food processing

Pond depth regulation made easy

Alfa Laval’s PondCtrl system makes it easy to control the amount of liquid in your decanter centrifuge during operation. This gives you benefits such as:

- Easier and quicker starts and stops

- Optimized cleaning

- Increased uptime and yield

- Easy process adjustment to compensate for feedstock variations

- Higher product quality

PondCtrl is available on new decanters, and as an upgrade for existing units.

How does the Foodec decanter centrifuge work

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. A stationary inlet tube introduces the product into the bowl, and a distributor gradually accelerates it. Centrifugal forces separate solids from the liquid. The solids are collected and compacted on the bowl wall.

A conveyor rotates inside the bowl at a slightly different speed. This transports the settled solids on the bowl wall towards the conical end. Foodec's design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl, and the clarified liquid leaves through a paring disc (internal centripetal pump).

All wetted parts in Foodec decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.

Optional features

Alfa Laval Foodec decanter centrifuges for food processing are available with other options based on your specific operating requirements.

- Energy-saving power tubes can reduce the overall energy footprint. for applications where low energy consumption is important,

- A paring disc configuration, featuring a pressurized outlet if oxidation or foaming are a concern.

- For higher levels of hygiene, the Foodec Hygiene Plus model contains all the most advanced features for outstanding drainability and cleanability on the inside as well as the outside of the centrifuge bowl, including smooth surfaces, to help maintain optimal hygiene. Foodec Hygiene Plus units are also available with additional TrueStainless and SaniRibs options:

Watch the video on upgrading food decanter centrifuge with Hygiene Plus features for outstanding drainability and cleanability to maintain optimal hygiene for your processing.

TrueStainless™

Designed for long-lasting and unmatched hygiene.

TrueStainlessTM ensures solid stainless steel is used for the frame and other key parts that may be in contact with corrosive atmospheres, leading to optimal hygiene and longer equipment life.

SaniRibs®

The cleaner, more efficient way to transport solids.

Our unique seal welded ribs create optimal friction which offers better, more efficient solids transportation. This innovative technology also eliminates pathogen hot spots and allows for easy cleaning, meaning longer production runs, less manual maintenance, and improved profits.

Applications

Service

Maintenance of Foodec decanters is key for ensuring optimum process performance and best possible hygienic conditions.

Depending on process conditions (running time, type of raw, process temperature, number of CIP cycles etc.), Alfa Laval recommends having:

- a decanter inspection at least every 4-6 months

- a major service at least every year.

Qualified Alfa Laval field service engineers can perform inspection and service either on site or in an Alfa Laval service center.

Maintaining bowl and conveyor in good condition is essential for hygienic process conditions and process performance. Bowl and/or conveyor repair is done at an Alfa Laval service center.

With connected services such as remote support and monitoring maintenance intervals can be extended. Maintenance, repairs, condition and remote monitoring can be bundled in a Service Agreement, tailor to your particular needs.

Alfa Laval also offers trainings for on-site maintenance staff.

Contact our dedicated service expert for a Service Agreement offer that is specially tailored to your needs.