LabUnit M10

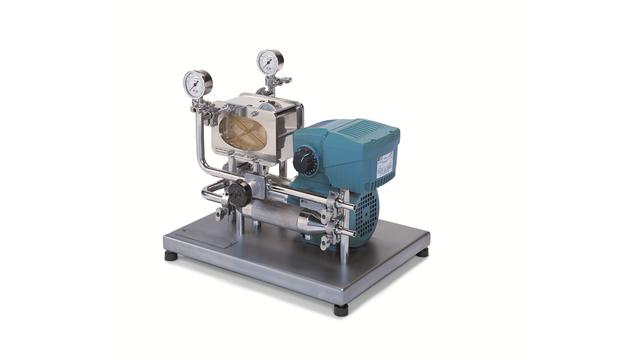

With a membrane area of only 336 cm², the Alfa Laval LabUnit M10 is our smallest and most compact cross-flow membrane filtration equipment. Fully integrated and easy-to-use, it is versatile enough for membrane screening, research, process development and training. It can be used with the complete Alfa Laval range of MF and UF flat sheet membranes and can test 2 different membrane types simultaneously, making it an effective tool for initial microfiltration or ultrafiltration membrane selection.

Fully integrated, easy-to-use laboratory equipment for membrane filtration

- Flexible and fully integrated –with LabStakTM M10 module, pump, pipework, valves, heat exchanger & instrumentation

- Easy to use – small test media volume, simple exchange of membranes and transparent plate for observation of cross-flow

- High operating temperature (80°C)

- Suitable for food and pharmaceutical processing applications – components comply with FDA and EEC regulations

Alfa Laval LabStak® M10

The Alfa Laval LabStak® M10 unit installed in the Alfa Laval LabUnit M10 is also available as a separate test unit for the same applications as the Alfa Laval LabUnit M10, and with the same distinct properties.

Product details

See technical data, components, connections, dimensions and further details of Alfa Laval LabStak M10 and Alfa Laval LabUnit M10.

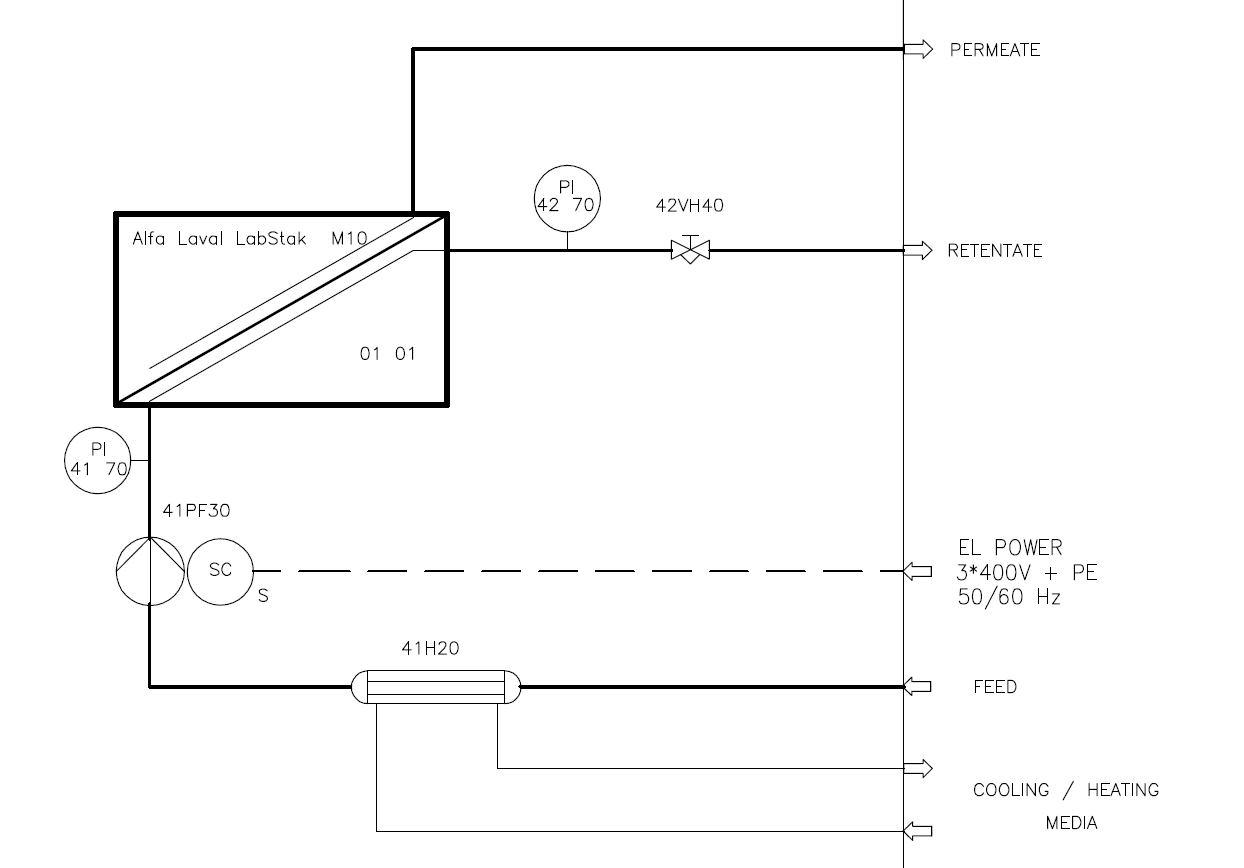

How it works

The feed stream/retentate flows through the open channels across the membrane surface in the plate-and-frame unit called LabStakTM M10 module.

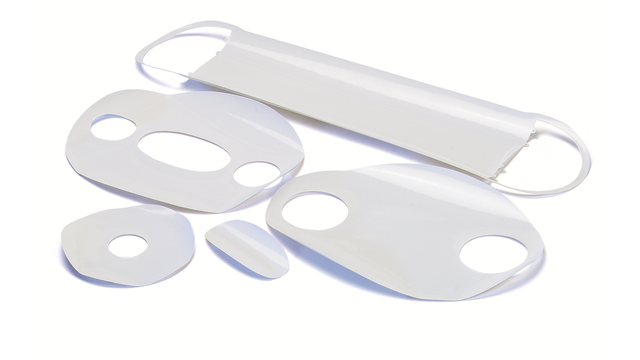

The membrane is supported by hollow plates with numerous slots that allow the permeate to be collected and removed from the unit via the permeate collecting tubes.

Plate-and-frame units use the membrane itself, aided by lock rings or strips, to seal off the feed/retentate and prevent any mixing with the permeate. This also prevents leaks from the plate stak itself.