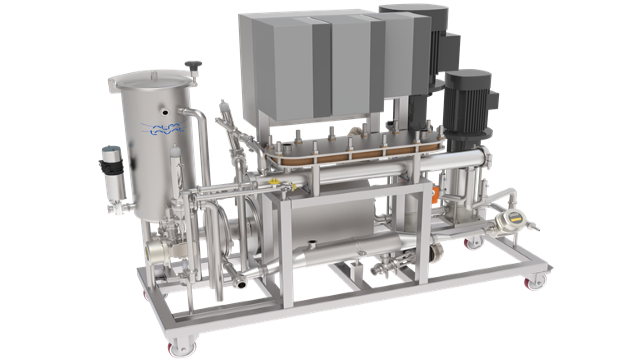

Standalone pilot plants

Alfa Laval membrane filtration lab units and membrane pilot plants deliver precise on-site testing to prove feasibility, validate membrane performance, optimize existing production lines and accelerate scale-up. With a broad range of membrane filtration equipment and deep industry know-how, our application experts support your process from first trial to full-scale operation with efficient service and smooth project execution.

Market leading laboratory and pilot membrane filtration equipment for testwork

- Get reliable answers to vital questions early on in your development cycle with membrane filtration pilot units

- Same design for both small-scale and industrial equipment allows seamless development of new processes and products

- Unlock cost-effective, data-driven full-scale system designs with expert support from Alfa Laval’s membrane specialists

- Fully integrated, compact and robust design that features low hold-up volume and flexible pump systems capable of handling a wide range of viscosities

- Compatibility with all feed spacers and pHt™ membranes, along with intuitive operation supported by built-in data logging

Testing membrane technology at your site or at our pilot facilities

We provide small-scale modules, units and membrane pilot plants for testing membrane filtration equipment and solutions on-site (rental or purchase) in connection with other process equipment. Our range of small-scale units and pilot plants is based on the unique plate-and-frame modules or the full-fit sanitary spiral elements or a combination of both. Sizes vary from only a few liters of test media volume in our LabUnits up to 1,000 liters in our PilotUnits. Designed for rapid delivery and long-term reliability, Alfa Laval's test equipment includes all key components – tank, pump, heat exchanger, valves, instrumentation and control.

We also do testing at our own state-of-the-art Membrane and Application Development Test Centre in Nakskov, Denmark. In both cases, we provide highly skilled process consultancy services.

Alfa Laval fully integrated membrane filtration equipment

The best membrane filtration solutions begin with curiosity. During early-stage trials, the seeds of innovation are sown: you test, measure and refine until a process reveals its potential. Then, big questions emerge: Can this process work? What data do we need to scale it up? How can we improve what we already have at our membrane pilot plant?

At Alfa Laval, our experience with membrane technology began nearly as long ago as the technology itself and spans all common types of membrane filtration. Today, we develop, manufacture, install and service reverse osmosis, nanofiltration, ultrafiltration and microfiltration membrane solutions and systems ourselves. That means, from your very first small-scale experiment to a full-blown production line, a team of guides who understand every step and every possibility will care for and dedicate themselves to every step forward in your unique journey.

Alfa Laval LabUnit M10

Alfa Laval TestUnit M20

How does Alfa Laval membrane PilotUnit Multi system work?

The Alfa Laval PilotUnit Multi comes as a skid-mounted unit and includes all necessary instruments, equipment and prefabricated piping ready for operation. All you need to do is to install and connect to the product feed, utilities and the power supply.

The product enters the tank via the feed valve (with level control). It is then pumped to the membrane filtration stage where the system automatically adjusts the pump speed and maintains the required cross-flow rate to reduce fouling and ensure the smooth concentration of your product.

The operator can adjust the controllers from the MemProC® PLC-based control system which includes a data logging system for the unit transmitters. The data can be downloaded to a USB.

Alfa Laval PilotUnit Multi has a flexible membrane area (3–15 m²) and can handle volumes between 50 and 1000 l. The basic unit is available with a number of options, including online monitoring and data collection, to enhance the performance of your membrane filtration process. You can double the spiral membrane area by adding another housing, while the addition of an Alfa Laval LabStak™ M39H module enables you to simultaneously test different MF/UF flat sheet membranes (up to 2 m²).

If you want to test our membrane filtration products for nanofiltration and reverse osmosis, you will find an option for this as well.

Alfa Laval LabUnit M20

The Alfa Laval TestUnit M20 offers a fully integrated system mounted on a wheeled stainless-steel table that includes the LabStak™ M20 module and all essential components – providing a mobile, professional setup perfectly suited for universities, technical institutes, pilot environments and advanced research facilities where flexibility and rapid experimentation are essential.

For the Alfa Laval LabStak™ M20 module, a unique combination of plate-and-frame and spiral-wound technologies in a single unit is possible. For a versatile system, the module can be equipped with a specially designed M20-2.5" housing, which fits easily between the module flanges and converts it into a spiral membrane test unit for sanitary full-fit 2.5" spiral membranes. This makes it an ideal tool for initial spiral element testing before screening on flat sheet membranes.

Watch the video on how to assemble an Alfa Laval TestUnit M20 in a 2.5-inch spiral configuration.

How to find the right membrane filtration equipment for your testing needs?

Whether you’re exploring early-stage trials, optimizing existing processes, or planning scale-up, the choices can be overwhelming. Let our Alfa Laval membrane experts guide you in identifying the most suitable membrane pilot equipment for your specific application.