Modules

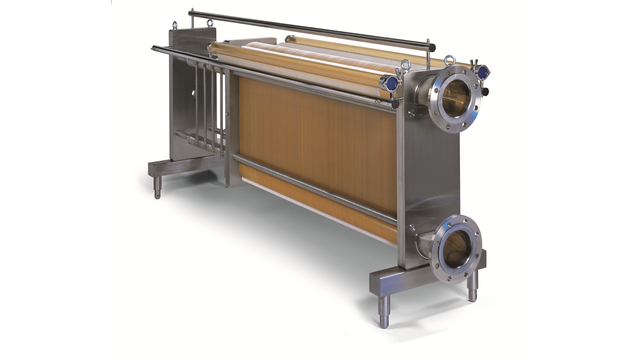

The unique open-channel design of Alfa Laval plate-and-frame membrane modules makes them suitable for virtually any viscosity, even for feeds containing suspended solids. These membrane modules are approved for sanitary operation and deliver significant advantages when product purity is critical and perfect cleaning and disinfection are essential.

Experience the benefits of Alfa Laval plate and frame membrane modules

- Open-channel design for highly viscous products

- Sanitary design ensures high product purity and easy cleaning

- Compatible membrane types for both plate-and-frame modules and spiral-wound elements

- Easy replacement of individual membranes

- Flexible modular design for customized solutions

Modular construction for easy cleaning, inspection and membrane replacement

The basic principles of membrane filtration remain the same whether the membrane is rolled into a spiral element or cut into flat sections for plate-and-frame units. Alfa Laval plate-and-frame modules use the same membrane types as our spiral-wound elements. The open-channel design makes them ideal for processes with viscous or particulate-laden feeds, or where frequent changeouts are required. Thanks to the modular design, individual membranes can be replaced without disturbing the rest of the module. Flexible configuration supports both small-scale trials and full-scale production.

What are the different Alfa Laval types of membrane modules?

Alfa Laval membrane equipment is designed on a modular basis, offering exceptional flexibility and scalability as your production grows: membranes are built into modules, modules are assembled into loops, and loops are integrated into complete systems. Our plate-and-frame module range includes the Alfa Laval M37, offering up to 27 m² of membrane area for ultrafiltration and microfiltration of highly viscous products; the Alfa Laval M38L/H, with up to 60 m² per module for low- to medium-viscosity applications; and the Alfa Laval M39L/H, also with up to 60 m² per module, designed for challenging feeds such as highly viscous products and fermentation broths.

Module M37

Engineered for ultrafiltration and microfiltration of high-viscosity products (50–250 cP) and fermentation broths, the Alfa Laval M37 module delivers reliable performance in biotech, pharmaceutical, food and beverage, and pulp and paper applications.

Module M38L/H

Developed for ultrafiltration and microfiltration of low- to medium-viscosity products (1–25 cP) and fermentation broths, the Alfa Laval M38L/H module is well suited for applications in biotechnology, pharmaceuticals, food and beverage processing, and the pulp and paper industry.

Module M39L/H

A proven favorite, the M39L/H plate-and-frame module is designed for efficient UF and MF of high-viscosity products (1–30 cP) and fermentation broths across biotech, pharma, and food and beverage sectors. Its optimized flow dynamics support low-energy and low-pressure operation for reliable performance.

How does Alfa Laval plate-and-frame membrane filtration module work?

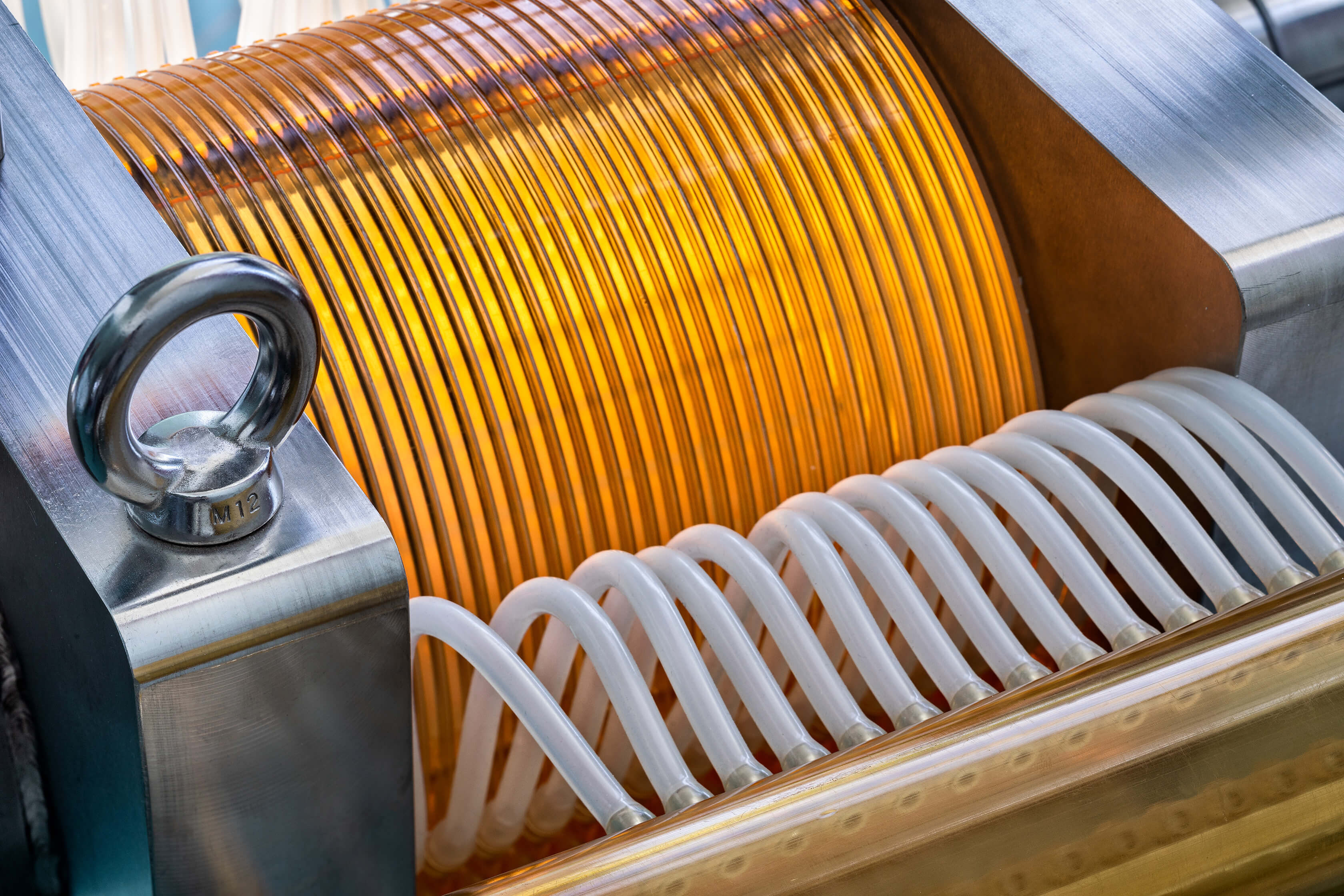

The plate-and-frame module from Alfa Laval is designed with open channels across the membrane surface. The feed stream/retentate flows through these.

The membrane itself is supported by hollow plates with numerous slots that allow the permeate to collect and be removed from the module via the permeate collecting tubes.

Plate-and-frame modules use the membrane itself, aided by lock rings or strips, to seal off the feed/retentate from mixing into the permeate channels. This also prevents any leaks from the plate stack itself.

Due to the design of the Alfa Laval modules, individual membranes can be replaced without affecting the other membranes of the module.

Plate-and-frame module M37

The Alfa Laval plate-and-frame M37 module is our high-concentration module for liquids of extremely high viscosity. Many products are non-Newtonian so tend to thin as flow velocity is increased. This effect is fully utilized in the extraordinary design of the thin-channel system of the module M37, making the modules usable for products untreatable by most other UF systems.

The module is available with membrane area sizes up to 27 m² and it can operate at temperatures up to 80°C, pressures up to 15 bar and pH between 1 and 14. It can be equipped with the entire range of flat sheet ultrafiltration and microfiltration membranes available from Alfa Laval.

Plate-and-frame module M38L/H

The Alfa Laval plate-and-frame module M38L/H is an energy-efficient module for the biotech and pharma industries where it ís used for the processing of antibiotics, amino/organic acids, dextrans etc. Also for food and beverage applications such as dairy, gums, sugar etc. the module is a popular choice.

The M38L/H module is available with plates having low (L) or high (H) channels and in various standard sizes defined by a membrane area up to max. 60 m² .

The module can operate at temperatures up to 80°C, pressures up to max 10 bar and pH between 1 and 14. It can be equipped with the entire range of flat sheet membranes available from Alfa Laval for ultrafiltration and microfiltration.

Plate-and-frame module M39L/H

The M39L/H module from Alfa Laval is a popular choice within the biotech and pharma industries, where it is used with great success for the processing of antibiotics, amino acids/organic acid, dextranes and industrial fermentation. Also for food and beverage applications such as dairy, gums, sugar etc. the module is widely used.

The M39L/H module is developed to meet the future demands for optimized flow dynamics, low energy consumption and low pressure operation. It is available with plates having low (L) or high (H) channels and in various standard sizes defined by a membrane area up to max. 60 m².

The module operates at temperatures up to 80°C, pressures up to max. 8 bar and pH between 1-14 bar. It can be equipped with the entire range of flat sheet ultrafiltration and microfiltration membranes available from Alfa Laval.

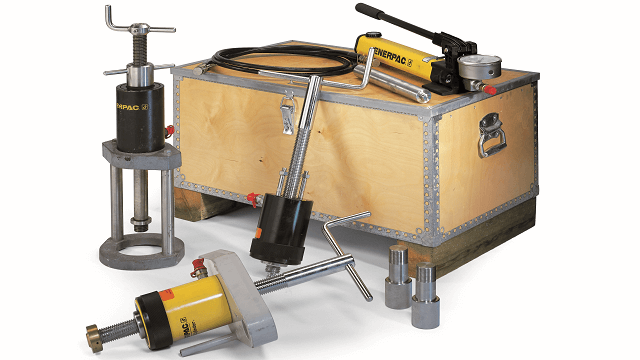

Alfa Laval auxiliary membrane equipment

Available in three versions for all Alfa Laval plate-and-frame modules, our hydraulic tools simplify the compression and decompression of the stack of flat-sheet membranes, plates, and flanges within the modules. Each hydraulic tool set includes a built-in hydraulic cylinder and a lever-operated hydraulic pump for efficient operation.

Powered by pressurized oil, these hydraulic tools deliver significantly higher operating pressures than comparably sized pneumatic tools. Additional benefits include greater force and optimized control for safe, reliable handling.

High permeate capacity

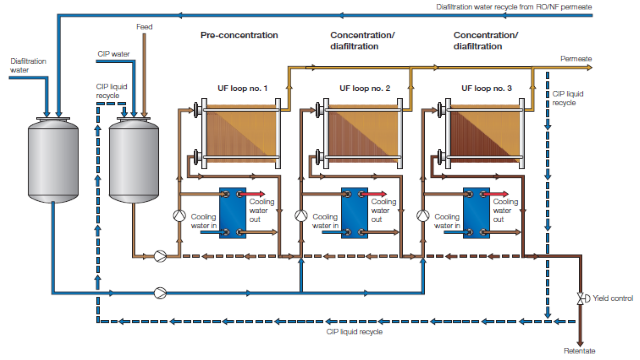

A plate-and-frame installation normally has a higher permeate capacity per unit of membrane area compared with what can be achieved using spiral-wound membrane elements. Industrial scale plate-and-frame modules have active membrane surface areas that range from 1.65 m² to 60 m². These can in turn be combined into larger systems using several modules placed either in series or parallel to achieve the required capacity.

The above illustration shows an Alfa Laval plate-and-frame system incorporating diafiltration, which is often used to process high suspended solids and viscous feed solutions.

Typical applications include the recovery of antibiotics from whole broth, concentration of enzymes and dextrans as well as clarification of juice.

The plate-and-frame process illustrated can be also be combined with for example an Alfa Laval spiral process, which gives the advantage of using permeate from the spiral process as diafiltration water in the plate-and-frame process. This significantly reduces the need for process water.

Need help with your module membrane?

Our dedicated Global Service Network supports you with parts and expertise in cross-flow membrane filtration, including nanofiltration, microfiltration, ultrafiltration and reverse osmosis. Because every plant is unique, we’re ready to hear your specific needs.