Brew series

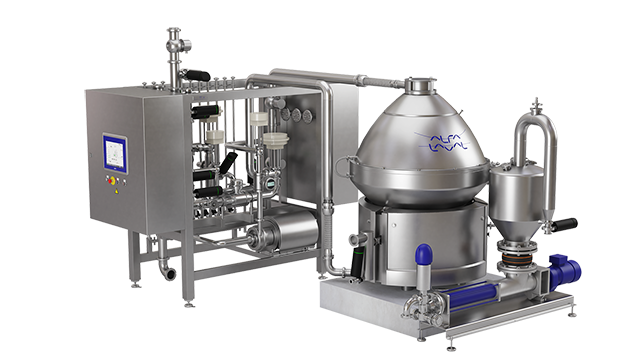

Alfa Laval beer centrifuges and separators have a long history of enabling breweries around the world to achieve higher yields, meet shifts in demand and maintain profitability. Used in pre-clarification, green beer separation, hot wort separation and beer recovery, they ensure minimal levels of oxygen pick up during passage through the separator and the highest standards of hygiene.

High beer separation efficiency combined with energy efficient operation

- Centrifugation provides breweries with swift beer clarification with no loss of aroma

- Increased clarification capacity: reduced fouling of filters with preclarification

- High efficiency beer separation enables quicker turnover of fermentation tanks

- Reduced product losses: beer centrifugation results in more concentrated solids compared to gravity settling

- Patented beer brewing equipment and hermetic design leads to low to zero oxygen pick up

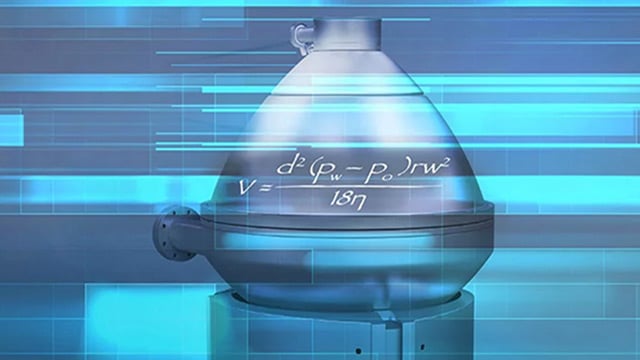

Clarification through separation helps increase the stability of the final beer. Our beer brewing equipment ensures gentle product handling through the utilization of a unique hermetic design. Turbidity measurement system and bowl speed adjustment functionality allows to achieve solids free crystal clear beers as well as hazy beers.

Stay upgraded

You can keep improving your Alfa Laval brew centrifuge's efficiency, sustainability, and hygiene with continuous upgrades. We inform you directly when an upgrade is available for your equipment. Visit our page to see all upgrades available.

Brew range

Our beer centrifuges have proved crucial in enabling breweries around the world to achieve higher yields and greater efficiency. They ensure minimal levels of oxygen pick-up during passage through the separator, which is a major quality requirement for brewers. Hygiene is also a prime focus of the design of our brewery centrifuges.

Brew 20

Multi-purpose centrifuge for craft brewers and microbreweries

- Up to 15 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Simple to operate

- Plug & Play skid

- Low maintenance costs

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Turbidity triggering of solids discharge (included in upgraded Plus version)

- Capacity control by inlet turbidity (included in upgraded Plus version)

Brew 250

Polisher for small breweries and сraft brewers

- Up to 180 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity (included in upgraded Plus version)

- Siemens or Allen Bradley Automation (included in upgraded Plus version)

Learn more about Brew 250 Plus

Want to know more about our smallest beer brewing centrifuge? Read more centrifuges for craft breweries.

Brew 301

Multi-purpose centrifuge for small breweries

- Up to 200 hl/h

- Low oxygen pick-up – OxyStop seal

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Siemens Automation

Brew 350

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic design for close to zero oxygen pick-up

- Low power consumption

- Complete system with full flexibility

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 350 Skid

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic design for close to zero oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 450

Pre-clarification and polishing duties in medium size breweries

- Up to 550 hl/h

- Hermetic design for close to zero oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Siemens or Allen Bradley Automation

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

Brew 600

Multi purpose for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 600e

Multi purpose for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 750

Pre-clarification and polishing duties in large breweries

- Up to 1000 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Brew 750e

Pre-clarification and polishing duties in large breweries

- Up to 1000 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Extremely low power consumption with eDrive (direct drive) and eMotion (reduced air friction)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Plug-and-play with complete associated system

The advanced technology of the Brew series goes far beyond the beer centrifuge itself. To make sure you get the best performance, Alfa Laval can deliver the entire system scope, complete with everything you need to ensure reliable and efficient separation. This includes automation solutions as well as all piping, valves and other relevant process components.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

Happy customers

Introducing Alfa Laval ConditionAlert™

The new Alfa Laval ConditionAlert gives you an eagle eye’s view of your brewery separator’s performance at all times. ConditionAlert proactively monitors separator condition and sends immediate alerts if actions are needed. Combined with Alfa Laval’s expert analysis, you have the vital information you need to ensure outstanding performance for your separator throughout its long lifetime.

A new top-of-the-line in beer separation

The Alfa Laval Brew 450 and 750 brewery centrifuges take our leading disc stack separation technology to the next level. Built with our unique, bottom-fed Hermetic Design, they deliver an unmatched combination of efficient separation and energy savings. That means increased yield and product quality together with enhanced flavour and aroma possibilities.

Take advantage of Alfa Laval features

All Brew models are developed with the benefit of Alfa Laval’s more than 130 years of experience with disc stack separation technology and our deep knowledge of customer processes. Find out how all that expertise has gone into unique features for improved separation performance.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.