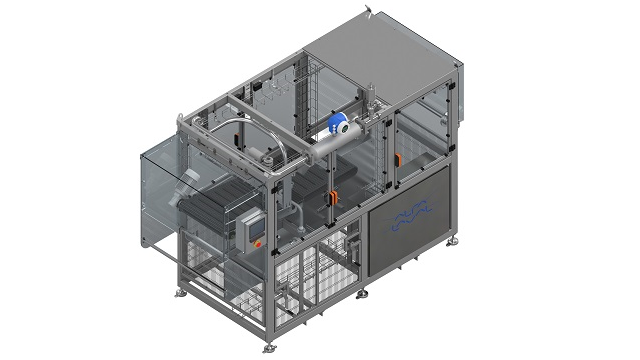

Bag-in-box fillers

Improve overall product quality and shelf-life while reducing the carbon footprint of your company’s packaging with Alfa Laval bag-in-box fillers. Compact, preassembled and pretested, these BIB filling machines handle high output speeds as well as quick changeovers between formats and production phases. Customize these bag-in-box fillers to your exact requirements for pilot- to commercial-scale production of food and non-food products.

A compatibility that no one else can match with our bag-in-box fillers

- Unmatched flexibility no matter the bag size, cap type or packaging design

- Safeguard product quality and shelf life with hot-fill capabilities and no oxygen pickup

- Increase productivity and yield thanks to higher output speeds

- Global expertise and service network with local service centres

- Reduced carbon footprint and more flexible, sustainable packaging compared with rigid alternatives

Lift productivity, quality and shelf life while reducing the total cost of ownership with Alfa Laval bag-in-box filling machines. these compact, scalable, high-speed filling machines range from pilot- to commercial-scale systems. Preassembled and pretested, they are fully customizable.

Take advantage of greater flexibility, no matter the bag size, cap type or packing design. Choose from stand-alone units or systems integrated with cartoning units, pasteurization tanks and modules. Then select the automation, alarm and diagnostics systems to meet your requirements. Behind all Alfa Laval bag-in-box equipment stand a global organization and vast processing experience.

Bag-in-box filler selection guide

Astepo Piccolo filler |

|

Astepo Clean filler |

|

|

Number of heads |

1 |

1-2 |

1-2 |

|

2" filling head for particles |

✔ |

- |

- |

|

Low acid products |

- |

- |

- |

|

Ultra Clean Kit |

✔ |

✔ |

✔ |

|

Automatic bag feeding system (1") |

✔ |

✔ |

✔ |

|

3-20 litre bags- consumer use/catering |

✔ |

✔ |

✔ |

|

200 litre bags- industrial use |

✔ |

- |

✔ |

|

1000 litre bags- industrial use |

- |

- |

✔ |

|

Max. speed (bags per hour) |

200 |

700 |

350 |

|

Stainless steel totes filling option |

- |

- |

- |

|

Filling with flow/mass meter |

✔ |

✔ |

✔ |

|

Filling with loading cells |

✔ |

- |

✔ |

|

Hot filling version |

✔ |

✔ |

- |

|

US Food and Drug administration (FDA) |

- |

- |

- |

|

European Hygienic Engineering & Design Group (EHEDG) |

- |

- |

Compliant |