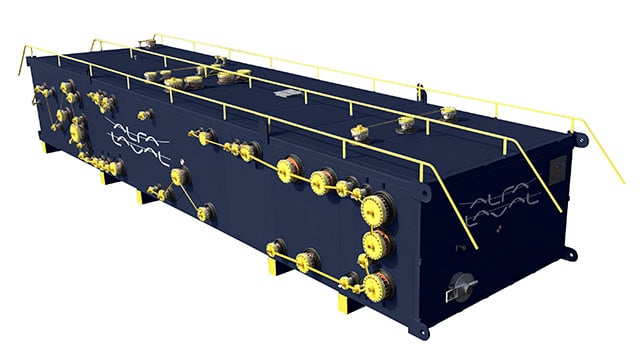

Core-in-drum

Core-in-drums are leak-free industrial heat exchanger assemblies developed for complex installations. Built to the highest industry quality standard, they consist of one or more cores of brazed aluminium heat exchangers (BAHX) enclosed in a carbon or stainless-steel pressure vessel. One fluid is in the drum. The others are internal to the core. This, to provide energy efficient heat transfer while the core is protected from external mechanical mechanical stresses and environmental conditions.

Experience the benefits of Core-in-drum heat exchangers

- Compact and integrated design

- Enhanced mechanical protection

- Simplified installation

Alfa Laval Core-in-drums are ideal in for harsh cryogenic environments thanks to their compact and integrated design, enhanced mechanical protection and simplified installation.

What makes Core-in-drum heat exchangers unique

Core-in-drums are a single unit solution that combines an energy efficient heat exchanger core inside a pressure vessel.

• Designed for high-performance cryogenic processes

• Reduces installation complexity and footprint

• Offers robust protection for internal components

How the Core-in-drum heat exchanger technology works

Core-in-drums work as a two-part configuration within a single unit. The BAHX core fitted inside a Core-in-drum is specifically designed to cope with more complex installations, while the stainless or carbon steel casing fits the highest quality standards, making it the perfect partner in demanding cryogenic processes.

Related products

Service

Alfa Laval offers global service support for commissioning, maintenance, and spare parts. Digital service options are also available for remote assistance.