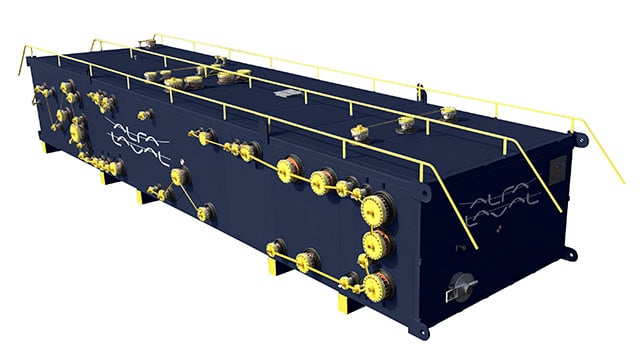

Cold boxes

Cold boxes are fully assembled collections of cryogenic heat exchangers, piping, valves, etc., insulated and protected from external elements like rain, snow, and wind. The steel casings act as an envelope for plug-and-play installation, protecting the brazed plate-fin heat exchangers, distillation columns, piping, valves, and instrumentation.

Experience the benefits of Cold boxes

- Easy installation and heat exchanger integration.

- Welded carbon-steel sheets that protects from the elements.

- Custom solutions to boost efficiency and extend Cold Box lifecycle in your specific application.

The durable carbon steel structures are the ideal partner for any cryogenic installation thanks to the easy installation, welded carbon-steel box, and the custom solutions we offer.

World-leading Cold box design

With over 65 years of expertise in cold box design, production, installation, and maintenance, we have made-to-measure solutions in operation all over the world.

- Suitable for easy onsite installation both on and offshore.

- Fitted with a nitrogen purge system containing stainless steel beams

- From 100-1,000 metric ton weights and temporary support materials for safe transport and vertical installation.

How Cold boxes work

The unique, customizable design allows for horizontal transport and vertical operation, with built-in structural and thermal protections. This consists of a nitrogen purge system and stainless-steel beams that support the enclosed equipment, optimizing efficiency and the lifecycle of your equipment.

Related products

Service

Alfa Laval’s CryoSens analytics software is a simple way to boost energy efficiency and improve operations. It evaluates the key elements of a heat exchanger, predicting any maintenance issues and offering easy solutions to avoid costly downtime.