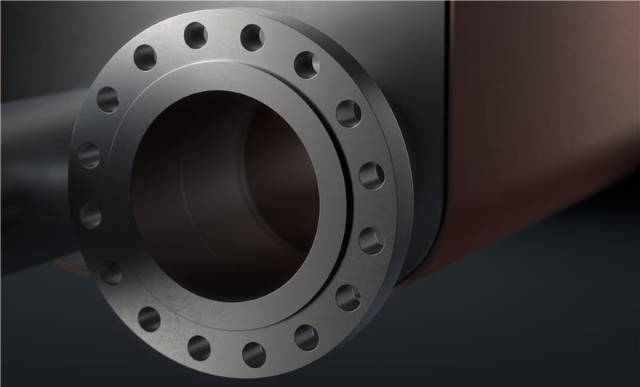

Brazed plate-and-fin heat exchangers

Brazed plate-and-fin heat exchangers are part of Alfa Laval’s next-generation solutions for efficient, compact heat transfer. These innovative heat exchangers are specifically engineered for mid- to large-scale cyclic gas-to-gas and gas-to-liquid applications, delivering excellent thermal performance, minimal pressure drop, and high operational reliability. Contact us to learn how this new technology can enhance performance and efficiency in your operations.

Benefits

- Excellent reliability under cyclic operation at pressures up to 100 bar (1,450 psi) and temperatures up to 200°C (392°F)

- Outstanding heat transfer efficiency with very low approach temperatures and even crossing temperatures

- Optimized for highly asymmetric gas-to-gas and gas-to-liquid duties, offering minimal pressure drop and high thermal performance

- Very high surface-to-volume ratio results in exceptional thermal capacity in a very compact format

- Available as standardized models with fast delivery, or as tailored designs for maximum performance flexibility

Unique features

SuperFin

Unique geometry for maximum efficiency and reliability in gas applications

The SuperFin design provides an extremely high surface-to-volume ratio, maximizing heat transfer in a highly compact unit. It also minimizes pressure drop and delivers exceptional structural strength and flexibility, making it ideal for cyclic gas applications involving high pressures and temperatures.

SigmaCore

High-strength materials for robust performance

Leveraging high-performance materials like stainless steel ensures exceptional strength, corrosion resistance, and structural integrity under high pressures and temperatures, enabling reliable, trouble-free operation in demanding duties.

VariFlow

Optimized for asymmetric flows

VariFlow enables full flexibility in handling asymmetric flows in gas-to-gas, gas-to-liquid, and liquid-to-liquid duties. This allows heat exchangers to be precisely optimized for applications with large flow imbalances, maximizing efficiency and performance without oversizing, or compromising pressure drop.

Meeting the challenges of gas-based processes

As many industries shift towards gas-based processes, the demands on heat exchangers are evolving. Gases have much lower thermal conductivity than liquids, making efficient heat transfer significantly more challenging. Conventional technologies often require oversized units to compensate, driving up CAPEX, increasing installation complexity, and limiting scalability. Another key challenge is maintaining a low pressure drop, especially in low-pressure systems.

Alfa Laval’s new brazed plate-and-fin heat exchangers are engineered to address these challenges. With a high surface-to-volume ratio, they combine compact dimensions with excellent thermal efficiency and minimal pressure drop. They are specifically designed to withstand cyclic operation, ensuring robust and reliable performance.

Optimized for gas-to-gas and gas-to-liquid duties at moderate pressures and temperatures, Alfa Laval’s brazed plate-and-fin heat exchangers are the ideal solution for energy storage systems, compressor cooling, industrial heat pumps, and refrigeration applications.

Ideal for all types of compressor duties

Compressor cooling

With high thermal efficiency and low pressure drop, plate-and-fin heat exchangers are perfectly suited for compressor cooling in multi-stage gas compression systems, where they improve compressor efficiency or throughput.

Industrial heat pumps

Their low refrigerant charge, tight temperature approaches, and ability to handle cyclic operation under high pressures make plate-and-fin heat exchangers ideal for boosting the energy efficiency of large-scale industrial heat pump systems.

Energy storage

Plate-and-fin heat exchangers enable efficient heat recovery in thermal energy storage applications – including molten salt systems – ensuring high roundtrip efficiency.

Refrigeration systems

The compact footprint, low refrigerant charge, absence of gaskets, and excellent reliability make plate-and-fin heat exchangers a smart choice for large-scale refrigeration systems.

How it works

Just like a traditional plate heat exchanger, a plate-and-fin unit distributes the hot and cold streams across multiple channels separated by plates.

The key difference compared to a traditional plate heat exchanger is that numerous small fins connect the plates in each channel. These fins form a network of channels and increase the surface area dramatically. As a result, plate-and-fin heat exchangers achieve excellent thermal performance while keeping unit size to a minimum. The large number of channels also results in an exceptionally low pressure drop.

The unique combination of compact size, minimal pressure drop, and high thermal performance makes plate-and-fin heat exchangers particularly well suited for gas-to-gas and gas-to-liquid duties. These applications are often challenging due to the low thermal conductivity of gases, but the extremely large surface area in a plate-and-fin unit effectively overcomes this limitation.

With a brazed, fully sealed construction reinforced by the fin structure, Alfa Laval’s brazed plate-and-fin heat exchangers offer robust, reliable performance for cyclic duties at moderate pressures and temperatures.