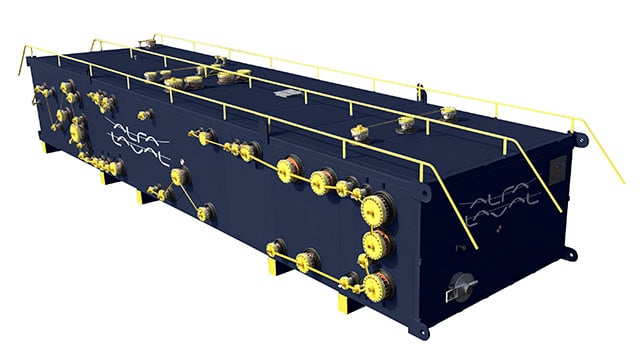

Brazed aluminium heat exchangers

Brazed aluminium heat exchanger (BAHX) technology offers a reliable and energy efficient heat transfer solution to the cryogenic industry, as it optimizes heat exchange at extremely low temperatures. Alfa Laval provides high-performance brazed aluminium heat exchangers, maximizing thermal efficiency. Ideal for demanding applications in gas processing and liquefaction, they are widely used in olefin, liquefied natural gas (LNG) processing applications as well as production of industrial gases.

The benefits of brazed aluminium heat exchangers

- 2,000 m²/m³ surface area — 4 to 5 times more efficient than conventional exchangers.

- Can operate at down to at 2–3°C temperature differences, reducing energy consumption.

- Reduces downtime to less than 0.01%.

The low-footprint heat exchanger is perfect in the cryogenic industry, saving customers on costly downtime and maintenance costs.

Brazed aluminium heat exchangers stand the test of time

With a century of experience in the cryogenic industry and over 16,000 units in operation, we have the expertise to fit any specification.

- In-house simulation software based on 25+ years of R&D and tests.

- Developed for reliable performance in the most complex installations.

- Customizable designs with pressures up to 140 bar and various fin types.

How the brazed aluminium heat exchanger technology works

The BAHX units transfer heat by passing cryogenic fluids through a compact aluminium core. The brazed construction maximizes thermal efficiency and mechanical integrity, making them ideal for demanding applications in gas processing and liquefaction.

Related products

Service

Alfa Laval offers local and remote services via a global network of expert technicians. With over 100 sites in 30 countries, support includes commissioning, revamping, spare parts, and maintenance. Digital service solutions are available for urgent or remote needs.