Welded plate-and-shell heat exchangers

The Alfa Laval portfolio of welded plate-and-shell heat exchangers offer ultimate robustness for challenging high pressure process duties. They are designed for high temperatures and high pressures, primarily for clean process fluids. The units deliver efficient heat transfer with a small footprint, which makes them ideal where space is restricted.

Reliable efficiency

- Higher process yield thanks to a low pressure drop, optimal liquid/gas mixing, high operating flexibility and a fully customized design

- Lower OPEX – The high heat recovery leads to important energy savings

- Lower CAPEX – A single Packinox can replace several large shell-and-tubes

- Lower maintenance costs due to minimal fouling

- Real-time monitoring and continuous optimization by Alfa Laval experts

Due to its many advantages, Packinox has become the industry standard combined feed/effluent heat exchanger in catalytic reformers and paraxylene plants. The potential OPEX reduction in these applications is significant, and choosing the right heat exchanger has a great impact on energy costs.

Thanks to the innovative design of Packinox+, the latest addition to the Packinox family, you can now optimize for highly asymmetric flows, opening up for a wider range of demanding duties.

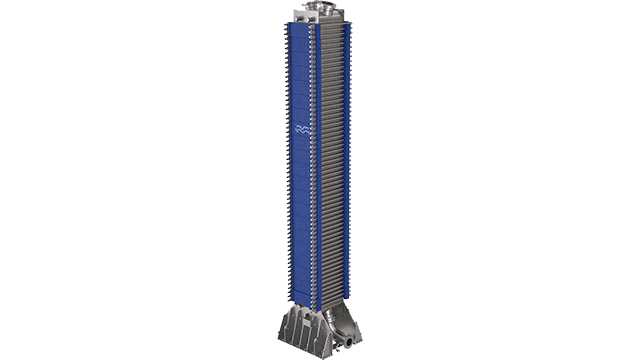

Packinox+

A Packinox+ heat exchanger is the optimal solution for large-scale heat recovery in industrial processes with high pressures and temperatures. The unique, welded plate design makes it possible to recover more heat in a single Packinox+ than in a system comprising multiple large shell-and-tube heat exchangers. The result is significant energy savings, reduced footprint, and lower CO2 emissions.

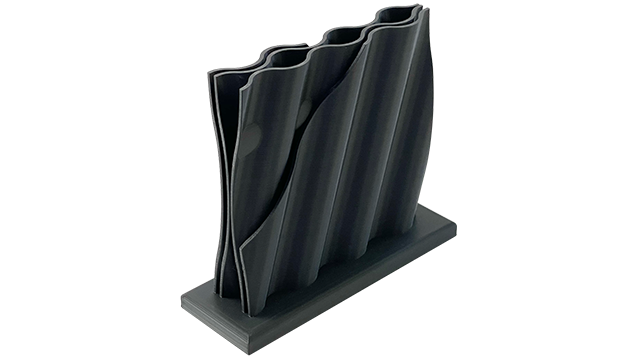

FlexFlow – for asymmetric flows

Until recently, Packinox heat exchangers were targeting duties with fairly symmetric flows. With the introduction of FlexFlow design the benefits of Packinox technology are now extended to a much wider range of applications and industries.

Packinox plate-and-frame heat exchanger

The plate-and-frame version of Alfa Laval Packinox has no pressure shell and no Spray Bar system. It is suitable for applications where the extra pressure and temperature resistance provided by the shell is not required, and where no separate liquid feed injection/flash evaporation takes place inside the heat exchanger. Applications include carbon capture and storage, energy storage, oil refining, petrochemicals and many more.