Cryogenic reciprocating pumps

Cryogenic reciprocating pumps transfer liquefied gases at high, medium, and low pressure, with medium and low flow rates. They are used in liquefied natural gas (LNG), liquid hydrogen (LH2), marine, air separation units, and other cryogenic applications. With a century of experience in the heat transfer industry, Alfa Laval Cryomec® reciprocating pumps maximize reliability and performance, while minimizing unwanted downtime.

The benefits of Cryomec® reciprocating pumps

- Less maintenance thanks to a long mean time between failure (MTBF)

- Suitable for LNG, LOX, LIN, LAR, LCO2, LN2O and LH2

- Available in simplex, duplex and triplex, configurations

The versatile reciprocating pump is ideal for the high-pressure capabilities of demanding cryogenic applications, offering reliable, energy efficient performance.

A cost and energy efficient solution

Alfa Laval’s high-performance reciprocating pumps deliver a cost-effective solution for demanding high-pressure applications. Thanks to lower maintenance needs and more reliable performance, you can minimize costs alongside waste product.

- Supercharger technology for optimal NPSHR ( Net Positive Suction Head Required ) performance

- Marine class certification available

- Vacuum-insulated cold-end to minimize product loss

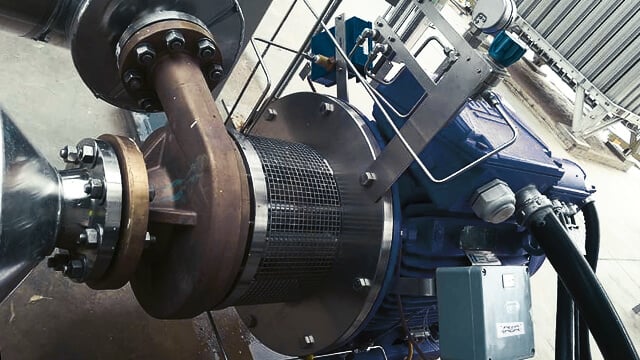

How reciprocating pump technology works

Cryogenic reciprocating pumps use a piston mechanism to transfer cryogenic fluids at high pressure. Their design ensures minimal wear and high efficiency, making them ideal for intermittent and continuous operation in demanding environments.

Our cryogenic reciprocating pump offering

Cryomec® DeltaN pump: the cost compressor

Widely used in cylinder-filling applications and air separation unit (ASU) projects.

Known as a cost-compressor pump, the Cryomec® DeltaN integrates a number of technical innovations that enable it to reduce pump downtime and overall cost of ownership.

The pump’s patented Cryomec® Supercharger technology improves efficiency, leading to very low Net Positive Suction Head Required (NPSHR). The perfect match for strict requirements.

Available for all cryogenic liquids, it offers flow rates of 2 to 85 L/min (0.42 to 22.5 gal/min).

Cryomec® KPS pump: proven technology

With a 40-year track record, the Cryomec® KPS high pressure pump is especially designed for CO2 and N2O filling stations.

Low operating costs, flow rates from 1 to 30 L/min (.21 to 6.6 gal/min), and pressures from 15 to 110 barG (217.56 to 1,595.42 psiG).

It is available with a variety of control systems, automizing operation and reducing any human intervention.

Cryomec® THOR pump: the most reliable on the market

Perfect for high-pressure liquefied gas processes in heavy-duty industries.

Initially developed for LNG, Cryomec® THOR pumps also suit the specific needs of air gas applications, maximizing flow rates, efficiency, and reliability.

Cryomec® LPRP pump: medium pressure, high performance

Dedicated to low/medium-pressure processes with low/medium flow rates, the Cryomec® LPRP pump is widely used by industrial players in the gas supply chain—from processing to distribution, at excellent safety levels.

Hy-Filling 450 and 900

High-performance and cost-effective high-pressure pumps for road and off-road vehicles, heavy mobility, trains, and captive mobility (forklifts) for LH2 applications

Related products

Service

Alfa Laval offers global service support including commissioning, maintenance, and spare parts. Digital solutions are available for remote diagnostics and urgent interventions.