ThinkTop® V70

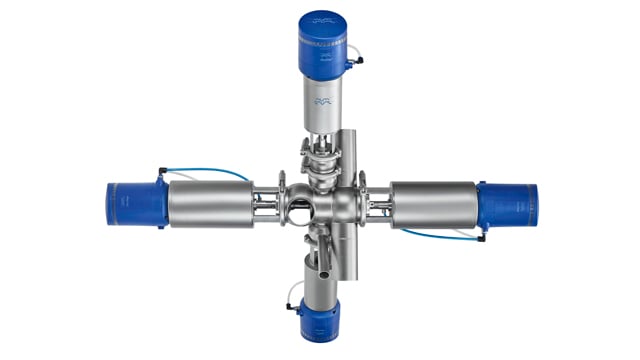

The compact Alfa Laval ThinkTop V70 is the second-generation of the leading sensing and control units for hygienic valves. It can be fitted with up to three solenoid valves and ensures unmatched control of all Alfa Laval valves used in the dairy, food, beverage, brewery and pharmaceutical industries.

Intuitive, intelligent hygienic valve control

- Fast, intuitive setup takes place in seconds

- Smart control with 24/7 self-diagnostics

- 360° LED visual status indication, visible from any direction

- Built-to-last: IP69K rating and vibration proof

- Fastest ever burst seat cleaning reduces water consumption by up to 90%

Maintain your peace of mind and control your hygienic valves effortlessly with the Alfa Laval ThinkTop V70 valve control units. Enjoy minimalist aesthetic housing made of composite material with a single sensor target control board to handle all valve functions and communication. No adapters, special tools or cover screws required. Non-crossing, colour-coded air hoses ensure straightforward connections.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Documents

Download

How it works

The Alfa Laval ThinkTop V70 valve control units offer a single-sensor solution for butterfly, single-seat and mixproof valves; a single control unit can be fitted with up to three solenoid valves. ThinkTop valve control unit converts the electrical PLC output signals into mechanical energy to energize or de-energize the air-operated valve, using the physical sensor target mounted on the valve stem.

Installation with auto setup is intuitive and fast. To initiate auto setup, simply press the “Select” button and then the “Enter” button to begin the setup sequence. The process is completed in accordance with the number of solenoid valves fitted to the control unit. Alternatively, the ThinkTop valve control unit can be set up without dismantling the control head using the built-in “Live setup” feature for remote configuration.

Alfa Laval ThinkTop®. Rethought.

Intuitive & Fast |

Smart & Adaptable |

Durable & Reliable |

Aesthetic Design |

Easy-to-access digital service and support

Access the service instruction manual and videos online or get the direct support you need using a convenient QR code located on the Alfa Laval ThinkTop housing.

The V-series fits all Alfa Laval hygienic valves. Select the right Alfa Laval ThinkTop valve control unit for your hygienic process needs based on the number of solenoid valves required. The ThinkTop V70 series fits on top of all of these valves plus the Alfa Laval double seat valves and special valves.

Exploit the power of IO-Link

Demand more from your valves with the Alfa Laval ThinkTop IO-Link. The ThinkTop IO-Link enhances communication between your hygienic valves and Industry 4.0 automation systems. The point-to-point IO-Link communication protocol connects sensors and actuators, regardless of fieldbus, to your automation systems. This makes meaningful real-time data easier to capture, store, analyze and act upon.

- Enhanced flexibility which lets you change data parameters and process data from a remote automation system

- More uptime and less cost due to 24/7 data monitoring and diagnostics

- Comprehensive overview of data for timely preventative maintenance and optimized performance

- Clearly visible LEDs with customizable colours and a 'wink' function that makes it easier to locate a valve from the factory floor

Burst seat clean: sustainable water savings for mixproof valve cleaning systems

Save up to 90% of the Cleaning-in-Place (CIP) liquid used for mixproof valve cleaning with the Alfa Laval ThinkTop burst seat clean. Unlike conventional PLC timer-based seat lift cleaning, burst seat cleaning uses minimal water and cleaning media. In less than a second, high-impact bursts of CIP liquid effectively clean your mixproof valves, removing all residuals from seat surfaces and safeguarding process hygiene.

Pulse seat clean: cut CIP liquid consumption on drain valve cleaning by up to 95%

Drain valves comprise 20% of all valves in typical process plants. Imagine the water savings you can realize by adding the Alfa Laval ThinkTop pulse seat clean to your drain valve cleaning process.

In less than a second, an intensive jet of CIP liquid pulses through the gap between the valve house and valve seat, creating high turbulent flow and leaving the valve spotless. The result? Quick and effective cleaning, more uptime, and increased end-product yields.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Find a partner

Please contact us with any queries or questions.

Part of a broad Sensing and control range

Alfa Laval offers a comprehensive range of Sensing and control intended for hygienic applications in the dairy, food, beverage, home care, personal care, biotechnology and pharmaceuticals.

Discover a new generation of ThinkTop® valve control units

Want to learn how the evolutionary Alfa Laval ThinkTop V50 and V70 can improve production on your hygienic process lines? Faster and more intuitive. Smart and adaptable. Durable and reliable. More compact yet with a highly functional design. The Alfa Laval ThinkTop. Rethought.

Cut Clean-in-Place liquid costs by 90% with optimized valve cleaning process

Are you interested to reduce consumption of CIP liquids? In this article, learn more about how you can achieve substantial water savings during the valve cleaning process – without compromising on product hygiene and safety.

You might also be interested in…

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.