MIB

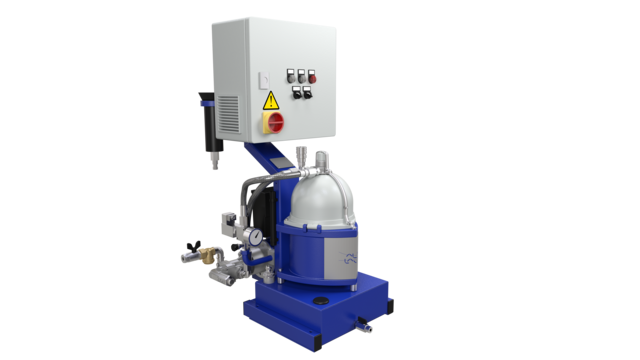

Cut maintenance time and costs with the Alfa Laval MIB series. Rely on advanced centrifugal separation for effective lubricating oil cleaning, soot and water reduction, and less engine wear. This lubrication oil purifier (LO Purifier) is smaller and lighter than traditional models, thanks to innovative design and drive technology. Keeping your engines cleaner and your operations stronger.

Efficient LO Purifier with lasting strength and minimal footprint

- New design allows you to clean the bowl with the disc stack still in place

- Direct drive with motor speed controlled by a frequency converter, eliminating gears and belts

- No lubrication required

- Small footprint allows installation in narrow spaces

- Biofuel ready – compatible with HVO (EN15940) and with FAME (EN14214 or ASTM D6751) blends comprising distillate

Installing, operating, and maintaining solid-bowl separators is now simpler than ever. The Alfa Laval MIB 303 and 503 systems feature innovative designs and materials to boost performance and make every task easier. Cut maintenance hours and enhance oil system reliability—perfect for low-contamination applications needing continuous treatment. Let’s make every day smoother, together!

Features that simplify separation

Easy installation

Require little in terms of utilities for operation – a power supply and heating are all that is required for the separator to work.

Easy operation

Designed to simplify operation and maintenance, reducing downtime and maintenance intensity and costs.

Direct drive system

The MIB LO purifier stands out with its innovative design, small footprint, and a direct drive system that eliminates the need for lubrication.

Collecting solids in the bowl

Designed to continuously separate liquids while collecting solids in the bowl provides a significant advantage by eliminating the need for a sludge tank.

Proven durability and performance

Built to optimize engine performance and enhance durability of the engine keeping the lube oil clean.

Biofuel ready

Compatible with HVO (EN15940) and FAME (EN14214 or ASTM D6751) blends, making them ready for biofuel applications.

How it works

Separation takes place in a rotating solid-wall bowl. Centrifugal force pushes water and solid particles outwards. Water collects in the seal, which drains into a channel underneath. Solids accumulate on the bowl wall and are easy to remove by hand.

Clean oil flows inwards and up to the paring disc. Since the clean oil is rotating, the stationary disc acts as a pump, forcing it through the outlet.

Real-life oil cleaning experience with Alfa Laval MIB separators

Achieving more with less effort

On many workboats and leisure vessels, reliability, time and money are in focus on the Dutch fishing vessel Prins Maurits. Using an Alfa Laval MIB 503 separator, Chief Engineer Auke van Slooten has doubled the life expectancy of his main engine’s lube oil, saving 1400 litres of oil a year and nearly two hours of cleaning time per week. Such results – and Alfa Laval’s close support – are the basis for a long history of cooperation.

Choose the ideal system for your application

The MIB 503 separator consists of a solids-retaining bowl which can operate both as a purifier and a clarifier. Because of the flexible design, it can be used to clean various oils

Distillate fuels (MGO/MDO) / Lubricating oils

MIB503 separators clean distillates and lubricating oils with densities up to 920 kg/m3 at 15°C and viscosities up to 150 cSt at 40°C.

Biofuels

The separator can treat distillate fuels according to ISO 8217 comprising FAME or HVO in any blend ratio,

- where FAME at the time of blending shall be in accordance with the requirements of EN 14214 or ASTM D6751.

- where HVO at the time of blending shall be in accordance with the requirements of EN 15940.

Other types of biofuels, such as vegetable oils or blends of FAME and HVO components outside the above-mentioned standards, should be evaluated on a case-by-case basis.

For these types of fuels please consult your local Alfa Laval office

Expert corner - get detailed insights on lube oil cleaning

Impact of IMO 2020 on marine engine lubrication

With changes in marine fuel types, lubricant requirements need to be reassessed. To remove insolubles and water from the lube oil, centrifugal separators are ideal to promote engine longevity and efficiency, regardless of the fuel type used.

How to reel in operational cost and extend equipment life

Efficient cleaning of fuel and lube oil is essential on a fishing vessel, just as on other vessels. Fuel and lube oil quality means smooth and trouble-free operations, which increase equipment lifetime and productivity. Centrifugal separation is not only the most reliable treatment technology, but also the most cost-effective.

Alfa Laval Marine Service

Worldwide and 24/7, Alfa Laval Marine Service is your path to greater uptime, optimized performance and true peace of mind. Our network is always on call, and our service offering brings reliability, efficiency and compliance throughout your equipment's lifetime.

24/7 Service & Support

Contact us anywhere, anytime:

+46 4636 7700

marine.service@alfalaval.com

Our global network of service centres centres, distribution centres and field service engineers is always ready at assist you.