Circular olive oil processing extracts valuable pomace olive oil from leftovers for producers in Spain

The olive oil producer, San Miguel Arcangel SA, in Spain uses evaporation systems and decanter separation technology to get much more from their olives – harvesting valuable antioxidants and pomace olive oil from the leftovers of the olive oil extraction process, as well as cleaning wastewater for re-use.

DATE 2024-03-21Located in southern Spain, San Miguel Arcangel SA is among the world’s largest olive oil refineries. Each year it processes 600,000 tonnes of wet husk or olive oil pomace – the stones, pulp, skin, and water that remain once the oil has been removed – from 40 olive mills in the province. This area alone produces a fifth of all the olive oil in the world and is known as ‘the sea of olive trees’.

“Olive oil pomace contains a small percentage of oil that cannot be extracted mechanically at the olive oil mills,” explains Alvaro del Rio of Alfa Laval, Spain. “However, it can be further processed to extract the pomace olive oil, and this, after further refining, has a market price that can compete with other refined edible seed oils.”

Before the residual pomace olive oil can be extracted from the wet husk, the olive oil pomace needs to be dried. This is traditionally done in trommel-type driers, which have a high energy and environmental cost.

“These driers use combustion gases at high temperatures to dry the wet husk,” says Alvaro. “However, this system has low thermal efficiency because the gases and water vapour are released into the air outside. In addition, the gas purification system to clean the particles in suspension from the smoke is very expensive.”

Alvaro Rio at the customer site in front of the evaporation equipment delivered by Alfa Laval.

“We proposed a partial dewatering of the olive oil pomace using the high-capacity three-phase X11 decanter, which has been recently developed for this application,” says Alvaro. “With this technology, we could remove approximately 50 percent of the total water and thereby double the capacity of the existing driers. Additionally, this decanter mechanically extracts the pomace olive oil, which has a higher value than pomace olive oil obtained through chemical extraction. As a result, the customer invested in three decanter lines that can process more than 1,000 tonnes daily.”

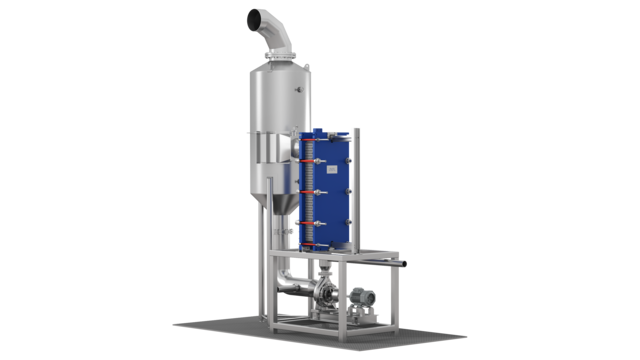

The San Miguel Arcangel also opted to invest in AlfaFlash evaporators, which concentrate the liquid discharge from the decanters at half the energy cost, since they consume 50 percent less thermal energy and 20 percent less electrical energy than traditional trommel drying. In addition, the forced recirculation ensures low fouling of the heat exchangers enabling continuous processing and minimizing downtime for cleaning.

“The resulting concentrate contains high levels of antioxidants, potassium salts and fulvic acids, which the pharmaceutical and cosmetic industries are very interested in for use in food supplements or skin cosmetics,” Alvaro says, adding that these oil-refining by-products are also a raw material base for the liquid fertilizer industry since both potassium and fulvic acids are key elements in fertilizers for a great variety of crops.

“Therefore, a product is obtained that couldn't be produced through traditional methods, and, when valorized, this greatly compensates for the processing costs,” Alvaro concludes. “And in addition, AlfaFlash produces distilled water that can be used in cooling systems, thus avoiding the consumption of well or mains water, and obtaining a very high environmental benefit.”

The AlfaFlash uses 50 percent less thermal energy than trommel-type driers. This enables an hourly saving of some 2.2 MW of thermal energy. This equates to an emissions reduction in the neighbourhood of 440 CO2-equivalent an hour.

Upcycling

By upcycling 600,000 tonnes of pomace from 40 olive mills, the customer produces 12,000 litres of olive pomace oil, typically sold at around 30 percent of the price of Extra Virgin Olive Oil.

Sustainable Food

Olive pomace oil is a well-known alternative to other edible oils, which in some cooking is preferable to extra-virgin and refined olive oils. The oil has a higher boiling point than other olive oils and is rich in antioxidants and vitamin E while neutral in taste. This makes it an ideal alternative to other oils for deep-frying. It is also a great alternative to ghee, made from clarified butter and the traditional choice of cooking oil in Indian cuisine. Cow ghee is notorious for its very high content of harmful trans-fatty acids, with a content of 4 g for every 100 g of ghee.

In 2018, the World Health Organization, WHO, cracked down on trans-fats and recommended that total trans-fat intake be limited to 1 percent of a person’s total energy intake. According to WHO, trans-fat intake leads to more than 0.5 mil deaths from cardiovascular diseases annually. Denmark was a pioneer in the field and introduced a ban on trans-fats in 2003. (source)

There is a natural content of trans-fats in animal fats, while a content of trans-fats in vegetable oils is an unfortunate side effect of the processing method. Alfa Laval plays a key role in the overall development of food safety worldwide, given that regulations tend to be largely driven by what is technically possible, i.e., by the best available technology.