Olive Oil Booster delivers top quality, high performance and sustainability for a family-owned producer in southern Italy

For Italian olive oil producer, Sacco Oliveti quality is paramount. The family-owned company has been producing extra virgin olive oil for decades from the distinctive Peranzana olives, grown across 6,500 hectares of ancient olive groves in Puglia.

DATE 2025-01-24

And this high focus on excellence was of utmost importance when the company decided to differentiate in the market by installing trailblazing production facilities to produce their top-quality extra virgin olive oil on a more industrial scale.

In the olive season of 2022, this new processing line increased oil yield by 15 percent – enabling the extraction of 1.5kg more oil from every 100kg of olives – with an accompanying increase in antioxidant phenol levels of 20 percent.

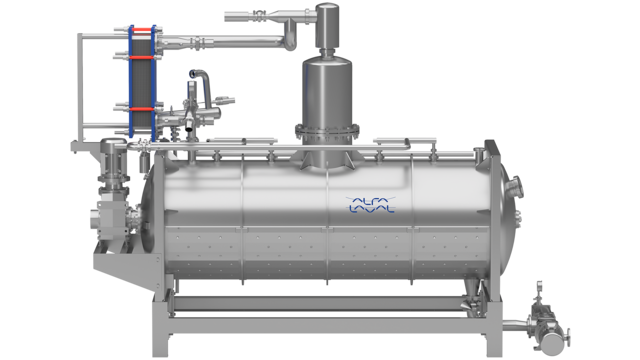

The turn-key extraction plant was supplied by Alfa Laval, who worked in close cooperation with Sacco Oliveti to ensure that the olive oil produced would be the best in terms of quality and quantity as had previously been extracted using more conventional methods.

A key element in the process is Alfa Laval’s new Olive Oil Booster, which uses vacuum technology to gently prepare the crushed and thermo-conditioned olives paste – heating and agitating at negative pressure until it is ready for the extraction process by the decanter.

“To achieve our unique quality objective in addition to ensuring the utmost care in the production of the olives, our project was looking for an extraction process that was equally unique,” explains Paolo Sacco from Sacco Oliveti. “We were looking for a technological solution capable of offering us process flexibility according to the characteristics of the olives at any time of maturation. A technological solution that was, at the same time, at the forefront of performance and sustainability.

“We found the right combination of technological competence, innovation and performance in Alfa Laval. The Olive Oil Booster technology, combined with the performance of the Sigma Decanter and the surrounding technologies, has represented, for our project, the perfect solution to producing the highest quality of oil with the maximum oil yield.

“After a year of experience, we can say that Alfa Laval has fully satisfied our expectations. In addition to confirming the results obtained in yield and quality, we can say that choosing Alfa Laval has also created a partnership – a competent and enthusiastic team that will travel together in the continuous search for the best performance.”

Since the first trials at customer sites in 2019, Alfa Laval’s Olive Oil Booster technology has been generating a high level of interest amongst Spanish and Italian processors keen to explore the benefits of higher yield and increased oil quality as well as the sustainable production gains of reduced water consumption and lower energy costs.

The advantages of using the Olive Oil Booster are very attractive, confirms Giacomo Costagli, Business Centre Manager Olive Oil in Alfa Laval’s Food & Water Division. Although it is a significant extra investment for customers, the payback time can be less than two years.

“With the application of the olive oil booster, the increased oil yield enables the extraction up to 1.5 kg more oil from every 100 kg of olives and in an industrial plant processing 3.5 tonnes of olives per hour, there is a specific energy (KJ) saving of 10 to 15 percent for Kg of oil produced, and a litres/hour saving in water consumption of between 5 and 10 percent,” he explains.

However, it is not only about an increase in the quantity of oil; Giacomo continues: “It is also about quality. With vacuum technology, more oil is extracted with the highest level of antioxidants and phenols up to 20 percent and full protection of aroma compound. As a result, we are helping customers produce more oil and higher quality oil – which is a significant win-win!”

Highlighted Technologies

Sacco Oliveti

Payback time

The payback time is typically 2 years.

Antioxidant phenols

20 percent higher content of antioxidant phenols.

Yield

Increased oil yield by 15 percent – enabling the extraction of 1.5kg more oil from every 100kg of olives.