Recycle pulp mill cuts energy costs by one-third; uses spiral heat exchangers to efficiently capture heat from white water

As one of the five top energy consumers in the state of Mississippiand with energy costs at an all-time high. the Mississippi RiverCorporation (MRC) needed to cut energy costs. MRC, a recycle pulp mill which produces pulp for large paper companies, started to investigate ways to minimize energy usage and increase profitability. The most obvious solution was to utilize a heat exchanger to recover heat from a hot white water stream. The fouling nature of the media ruled out shell-and-tube heat exchangers, which are difficult and time-consuming to clean. Plant operators finally selected three spiral heat exchangers based on their high efficiency and ability to handle fluids with fibers/particles such as those found in white water. This heat recovery system incorporating the spiral heat exchangers has cut MRC’s energy costs by one-third.

DATE 2025-12-09The spiral heat exchangers are being used to exchange heat between white water and mill water. As hot white water flows through the heat exchangers, it preheats the colder mill water. This mill water will eventually be used as a heating source in other parts of the plant. Therefore, by using the “free” white water as a heating source, MRC is able to reduce the amount (and cost) of steam required to further heat the mill water to a final desired temperature. The simultaneous cooling of the white water is also beneficial to the pulping process. The cooler temperature allows for easier removal of contaminates from the raw pulp in the subsequent de-inking stages.

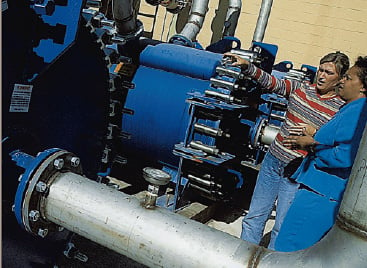

MRC has a total of three spiral heat exchangers in their heat recovery system. Two 426 m2 (1,400 ft2) units were installed and put in service in January 2001, while a third identical unit was installed in October 2001. Normally, two spiral heat exchangers operate in parallel, with the third unit as a standby. The purpose of the stand-by unit is to allow MRC to operate at full capacity, whenever any one of the three spiral heat exchangers needs to be taken off-line for cleaning. To date, however, more than a year later, the third stand-by unit has not been used as the two units in operation have not required opening or cleaning. Tanya Richardson, Process Manager at MRC reports, “These spiral heat exchangers are fantastic! They just continue to run without any decline in thermal and hydraulic performance! We started the original two units over a year ago and have not had to perform any type of maintenance on them. As a result of the increased heat recovery with these spirals, our company has been able to reduce energy usage by one-third. We have also realized significant savings in operating costs since the spiral heat exchangers have not required any maintenance or downtime. We are completely satisfied with the performance of these units.”

Products

Benefits

- A deep temperature cross is possible due to the long thermal length and the fully counter-current flow pattern.

- The single channel design maximizes fluid velocity and turbulence, which, in turn, minimizes fouling.

- The single channel design also prevents fluid bypassing eliminating the possible loss of heat transfer area.

- The hot and cold channel spacing can be varied independently to suit the concentration and size of fibers/particles in the fluid.

- The “self-scrubbing effect” occurs as a result of any accumulation of solids in the channel, which reduces cross-sectional area and thereby increases fluid velocity. This localized increase in velocity creates a scrubbing effect

- Cleaning-in-place (CIP) can be effective since the single channel design ensures that the active chemical agent reaches any fouled surface. Experience has shown that CIP can even replace mechanical cleaning, depending on the severity and type of the fouling.

- The compact but open channel design simplifies mechanical cleaning, should chemical cleaning prove ineffective. Unbolting and removing the cover provides full access to the hot or cold channel, which can be efficiently cleaned by a high-pressure water jet.

Customer's voice

These spiral heat exchangers are fantastic! They just continue to run without any decline in thermal and hydraulic performance! We started the original two units over a year ago and have not had to perform any type of maintenance on them

Tanya Richardson,

Process Manager