The sun's advocate

A solution from Alfa Laval increases the electrical generation time in concentrated solar power plants by 50 percent, making the sun a power source to be reckoned with.

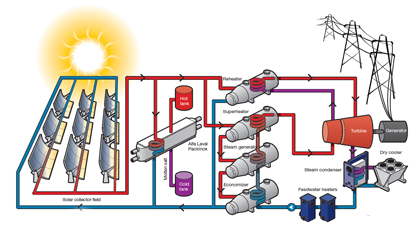

DATE 2025-12-17 AUTHOR Åsa LovellConcentrated solar power, or CSP, is one of the two main technologies to produce electricity from the sun’s energy. Until recently, CSP has been used to produce electricity only when the sun was up. This has been a problem, since the production does not fully match the typical demand curve for electricity. A solution to the problem is to add a thermal storage system based on molten salt, which allows the plant to generate electricity even when the sky is overcast and after the sun goes down without using a backup system powered by fossil fuels. This means the plant can operate for 18 hours straight instead of 12 hours – an increase of six hours or 50 percent. At the heart of the thermal storage system is an Alfa Laval Packinox heat exchanger specifically developed for this application.

Thanks to recent acquisitions, Alfa Laval can also supply other vital equipment to CSP plants, including a variety of heat exchangers, condensers and dry coolers.

1. Harnessing solar thermal energy

When the sun shines, it heats up thermal oil that goes through the solar panel array in a loop.

Each solar panel or mirror concentrates the heat onto the focal point of the mirror, through which the thermal oil passes.

A portion of the heated oil goes directly to power generation, where it is used to heat water into the steam that drives the steam turbine, which in turn drives the generator where the electricity is produced. The other portion of the hot oil goes to the thermal storage process.

2. Storing solar energy

The heat is stored in salt.

The salt is pumped out of the cold tank, through the Alfa Laval Packinox where it is heated by the oil, and into the hot storage tank.

When the sun is not available, like on cloudy days or after sunset, salt from the hot storage tank is pumped back through the Alfa Laval Packinox where it heats up the thermal oil. The heated oil is then sent to the power block to generate steam.

3. Stepwise steam production

In the steam cycle, water is turned into superheated steam in progressive steps to maximize energy efficiency.

These steps include preheat-ing, steam generation, superheating and reheating, with Alfa Laval Compabloc at the first, low pressure step, and Alfa Laval Olmi at all the other steps.

4. Closing the steam cycle

After the steam has delivered its energy to the turbine, it is back into water through Alfa Laval's condenser. The cold water that condenses the steam is cooled down with the help of Alfa Laval's air cooler. The condensed steam (water) goes back into the steam cycle to be reheated into steam.

The solar panel array can be used for heating thermal oil approximately 12 hours a day.

Thanks to the Alfa Laval Packinox heat exchanger that makes the thermal storage possible, the facility can instead generate electricity for up to 18 hours per day, representing a 50 percent increase in production time.