Two-in-one solution for BASF

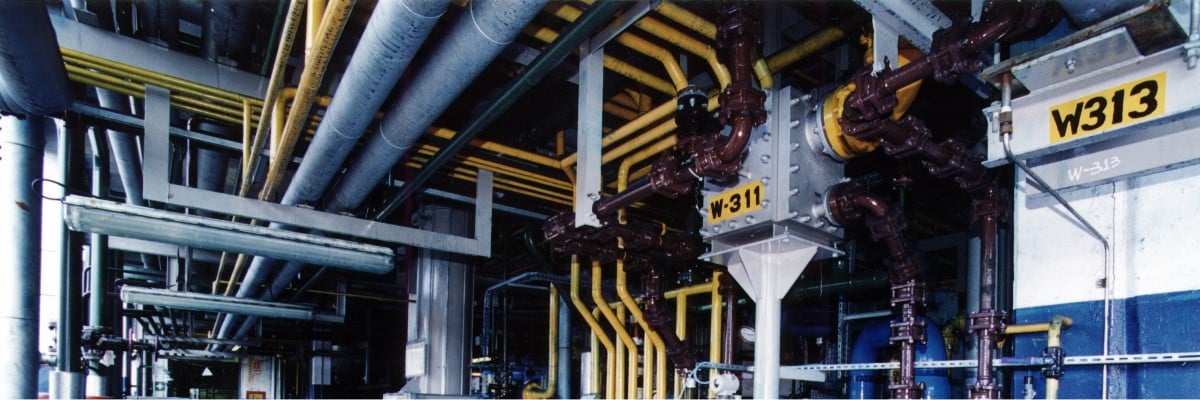

The largest BASF production facility in Latin America is the Guaratinguetá Chemical Complex, strategically located between the cities of Rio de Janeiro and São Paulo. The Guaratinguetá site consists of a total of thirteen plants that extend over an area of more than 1.6 million square metres. These provide hundreds of products, including expandable polystyrene, plastic dispersions, pigments, dyes, vitamin mixtures and products for use in agriculture.

DATE 2023-11-28In the pigment factory, however, BASF had a capacity problem. Two batch reactors shared the same shell-and-tube unit for condensing organic solvent, resulting in a bottleneck in production.

To solve this, BASF decided to link the existing shell-and-tube condenser to one reactor and purchase a new condenser for the other. The choice lay between an identical unit, a vertical shell-and-tube condenser with a carbon steel shell and graphite tubes, or a new Compabloc condenser in Hastelloy C-22 from Alfa Laval.

The compact, fully welded Compabloc heat exchanger is designed to operate with a wide range of aggressive media and at high temperatures and pressures.

I was really surprised when this little Compabloc unit, which is only a quarter of the size of the existing shell-and-tube condenser, proved to have almost double the capacity. To me, it seems almost like a miracle.”

Walter Misfeld, Production manager