Alfa Laval compact plate evaporators allow plant expansion in middle of city

The Absolut Company produces the world’s number one premium vodka in the picturesque fishing village of Åhus, Sweden. Every one of the 50 million litres of Absolut Vodka sold annually is distilled and bottled right in the centre of town in the midst of the shopping district. However, during the 1990s as production expanded to keep up with worldwide demand, the company faced the problem of increasing capacity without disturbing the unique architecture of the 850-year old town.

DATE 2025-12-11

The Absolut Company produces the world’s number one premium vodka in the picturesque fishing village of Åhus, Sweden. Every one of the 50 million litres of Absolut Vodka sold annually is distilled and bottled right in the centre of town in the midst of the shopping district. However, during the 1990s as production expanded to keep up with worldwide demand, the company faced the problem of increasing capacity without disturbing the unique architecture of the 850-year-old town.

This meant fitting all the process equipment into one plant that could be built on an empty lot on the premises and, at the same time, maintaining the historic look of the red brick buildings. One vital component in the distillation process is the heat exchangers and the heat transfer equipment for the new plant had to fit the strict requirements for compactness and energy efficiency. After extensive investigations, the Absolut Company chose Alfa Laval’s plate condensers and reboilers for all four distillation columns and could fit them into a fraction of the space needed for shell-and-tube heat exchangers.

We investigated falling-film shell-and-tube heat exchangers first but they were enormous and we had height limitations. We were sceptical of the plate evaporator but a visit to a reference plant in France and laboratory tests convinced us,” adds Agne. “The plate evaporators have performed excellently since they were installed in the autumn 1995 and, in fact, we haven’t opened them since we bought them."

- Agne Axelsson, plant distillation manager.

Energy-efficient steam generation

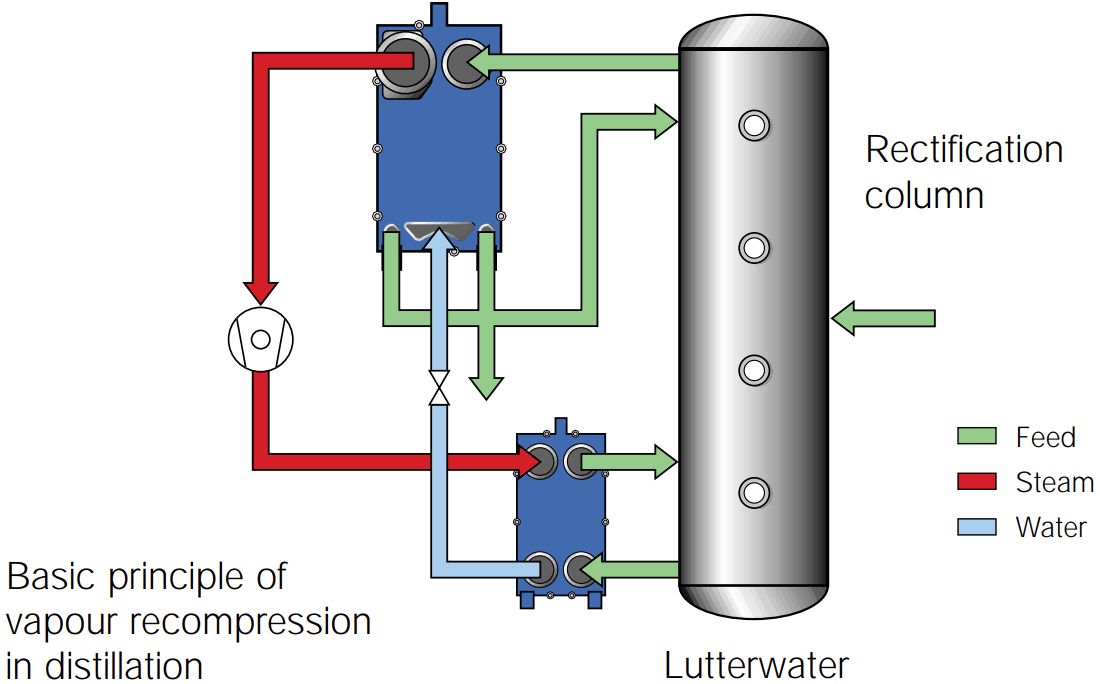

The Absolut Company’s state-of the-art plant in Åhus utilises a high-efficiency steam generation process in which heat from the condensing ethanol vapour is not wasted but used to produce the steam needed to feed the reboilers. This closed loop system minimises energy costs.

Vapour from the top of the columns is condensed in plate evaporators on the welded side of the semi-welded cassette. Low-temperature steam is produced on the gasketed side of the cassette by using hot sub-atmospheric water at the saturation temperature as a cooling medium. The plate evaporator’s large portholes and small condensate ports makes it perfectly suited for efficient handling of high-volume two-phase flows in both channels. The Åhus installation makes maximum use of this feature.

The steam temperature is increased by mechanical vapour recompression and then used as heating medium in Alfa Laval plate reboilers. The condensed steam is throttled to sub-atmospheric pressure and pumped to the plate evaporator/condenser to be used once again as a cooling medium before the loop is completed.

“Compactness and successful reference installations were the two most convincing features for the plate evaporator but the availability of service was another weighty argument. We also chose Alfa Laval because they can offer quick and competent service. Service is crucial for since we operate around-the-clock 11 months a year,” comments Agne.

“Another valuable feature of the plate heat exchanger design is its flexibility,” says Mikael Runeson, production director.

“We appreciate the fact that we can add or remove plates as processes and capacities change. When we discovered that the methanol content was much lower than expected, we simply removed plates from the plate reboiler serving the methanol stripper and added plates to the plate reboiler serving the rectifying column.”

The plate evaporator

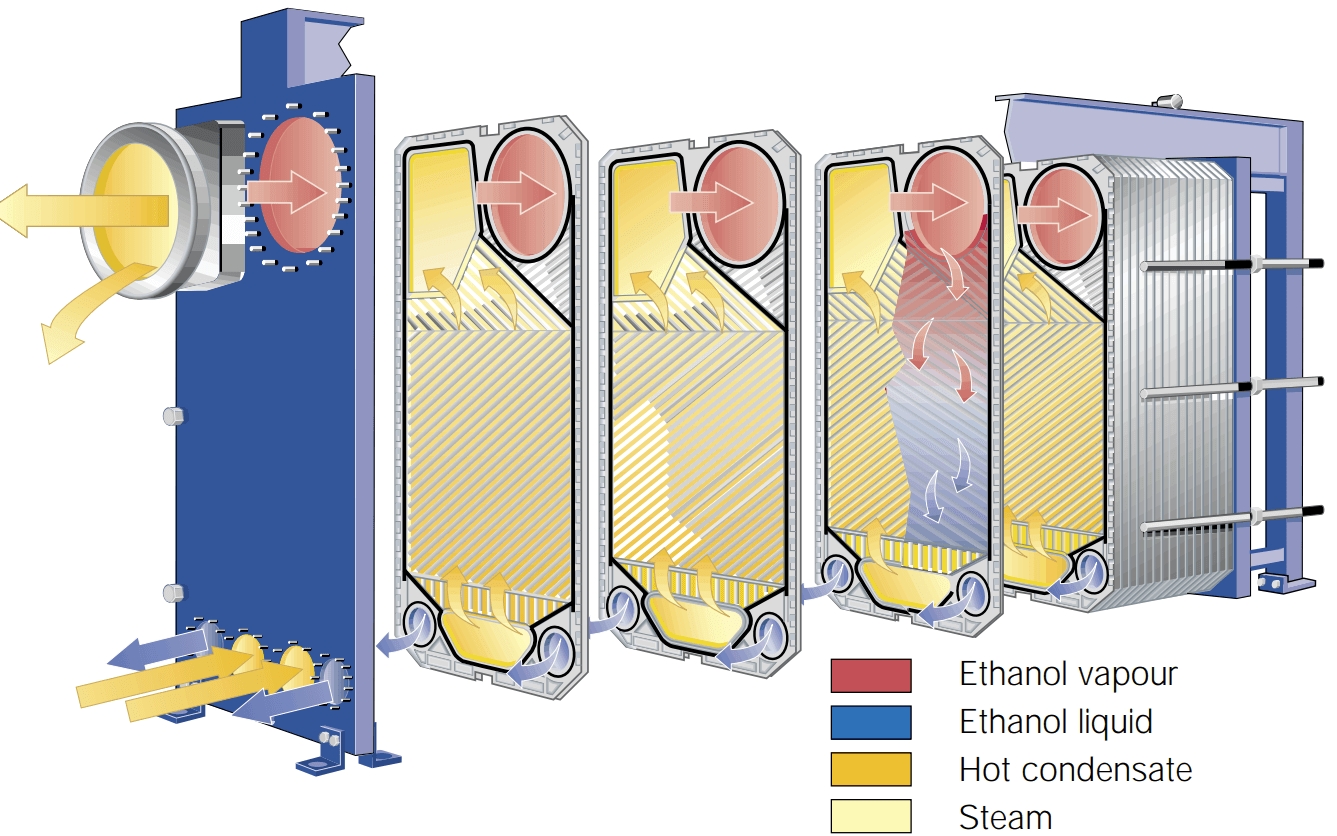

The plate evaporator consists of a plate pack assembled between a frame plate and a pressure plate and compressed by tightening bolts. The plates are welded together in pairs to form cassettes and gaskets seal the channels between cassettes.

The plate evaporator performs on the rising-film principle with the inlet for the medium to be evaporated located at the bottom. The vapour formed is discharged via the large upper connection. The standard plate material is AISI 316 but plates are available in any pressable material such as titanium, palladium-titanium and Hastelloy. The standard gasket material is EPDM or Nitrile but other elastomers are available on request. The plate evaporator’s large vapour ports and small condensate ports were developed to handle two-phase flows on both sides of the plate. The special plate pattern, which has a preheating area and an evaporation area, is designed with different herringbone angles across the plate in order to promote even flow distribution. The plate pattern also induces turbulence which, in turn, promotes heat transfer and minimises fouling.

Since its introduction in 1990, more than 700 plate evaporators have been sold to various processes in the cane and beet sugar industry, starch industry, food industry, distilleries and chemical processing industries.

Alfa Laval - an innovator in compact heat exchangers

The plate evaporator is just one heat exchanger innovation developed by Alfa Laval during the 70 years the company has been in the heat exchanger business. Alfa Laval is the world’s leading supplier of compact heat exchangers with a broad range of plate heat exchangers, brazed heat exchangers, spiral heat exchangers, reboilers, condensers and evaporators. A worldwide network of service centres on all continents on the globe offer customers additional operating security. Alfa Laval is a member of the Alfa Laval Group, an international organisation with its core businesses in heat exchange, separation technology and flow technology.

Products

AlfaVap reboiler works magic on any company's evaporation and condensation costs. AlfaVap units take up much less expensive space, thus greatly reducing the investment cost.

Benefits

- Save money

- Easier installation

- Lower temperature difference possible

- Easy to increase capacity

- Easy maintenance

Customer's voice

The plate evaporators have performed excellently since they were installed in the autumn 1995 and, in fact, we haven’t opened them since we bought them.

Agne Axelsson

Plant distillation manager