Alfa Laval SBR and Iso-Disc® tertiary filtration optimizes effluent quality and reduces operating costs

Owned by Agri Beef Co., the Washington Beef processing plant focuses intensively on sustainability. In its water reclamation facility, the plant has installed an Alfa Laval AS-H Sequencing Batch Reactor (SBR) for biological wastewater treatment and an AS-H Iso-Disc Cloth Media Filter for tertiary treatment. This solution helps ensure that the effluent water quality objectives are consistently achieved and offers the plant substantial cost savings in the areas of energy and maintenance. Biogas capture from the overall process now covers 20% of the plant’s natural gas demand.

DATE 2023-11-28With a history stretching back 45 years, Agri Beef Co. is involved in every step of the beef lifecycle, including cattle ranching and feeding, cattle nutrition, and beef processing, while striving to preserve natural resources through a range of sustainable practices. The company’s processing plant produces high quality boxed beef and byproducts, and is committed to preserving the pristine Northwest environment.

Wastewater treatment upgraded with an SBR

Previously, Washington Beef’s wastewater treatment process consisted only of dissolved air flotation (DAF) for separation of oil and grease and anaerobic lagoons for conversion of organic materials to methane gas.

Aiming to raise the efficiency of the process and to ensure compliance with the latest environmental legislation, Agri Beef decided to install a sequencing batch reactor (SBR) and a tertiary filtration system as the final steps. Alfa Laval was chosen as the partner for the project based on their technical evaluation and cost-competitive solution.

In 2010 Alfa Laval delivered a two-reactor AS-H Sequencing Batch Reactor System, with each reactor utilizing a 9 foot diameter, v-notch weir floating decanter. The Alfa Laval AS-H SBR system is an advanced technology for biological treatment of variable wastewater flows by means of activated sludge. It is particularly suitable for applications where influent flow and organic loads can vary and where effluent requirements are stringent.

Alfa Laval’s scope of supply also included turbo blowers supplying air to a high efficiency SBR diffused aeration system, SBR floating mixers, waste sludge pumps, valves and actuators for automatic operation plus multiparameter analyzers and sensors with dissolved oxygen (DO) and oxidation-reduction potential (ORP) probes for optimum control of the aeration system. Other deliveries were motor control center, instrumentation, PLC, and controls to achieve automatic and reliable performance plus start-up service and instruction on operation and maintenance of the system.

Iso-Disc chosen for tertiary filtration

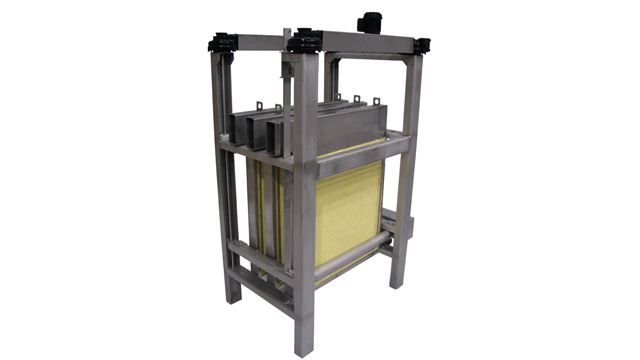

The tertiary filtration system delivered by Alfa Laval comprises the gravity driven AS-H Iso-Disc Cloth Media Filter technology. The fully submerged filter is capable of solids capture down to 10 microns and is highly efficient with a 100% utilisation of the filtration area.

New treatment process fulfils effluent discharge criteria Agri Beef’s upgraded facility treats the wastewater generated from the processing plant to effluent water quality levels which meet or exceed the American National Pollutant Discharge Elimination System (NPDES) permit to ensure safe discharge back to the environment.

After pre-treatment using DAF and anaerobic lagoons, the next step is the Alfa Laval SBR. This provides aerobic treatment of organic material, nitrification for oxidation of organic nitrogen and ammonia, and anoxic mix only sequences to achieve denitrification for the conversion of nitrates to harmless nitrogen gas and release to the atmosphere. Final effluent polishing prior to safe release back to the environment is accomplished by tertiary filtration using the Iso-Disc Cloth Media Filter.

The combined Alfa Laval solution helps ensure that effluent water quality objectives are consistently and efficiently achieved. The water reclamation facility achieves target values of BOD5 <20 mg/L, TSS <20 mg/L, and a TN of <20 mg/L.

Biogas from wastewater treatment saves costs

With the new SBR and tertiary filter processes online and consistently ensuring compliance with the NPDES permit, Agri Beef was able to move forward with additional improvements and upgrades. Within the first year of operation, the anaerobic lagoon was taken offline to begin the process of retrofitting to enable the capture of biogas, one of a number of sustainable practices implemented by Washington Beef.

With support from the Alfa Laval process engineering team, the plant operations team at Washington Beef was able to modify the operations of the wastewater treatment plant to remain in compliance while the modifications to the anaerobic lagoon were made.

These efforts have positively impacted overall plant sustainability as the biogas generated from the new process meets 20% of the processing plant’s natural gas demand, thus reducing costs and limiting the overall carbon footprint.

System benefits, savings and sustainability The Alfa Laval AS-H SBR’s floating decanter uses adjustable v-notch weir technology to decant at constant rates from top water level to bottom water, which facilitates optimum sludge settling and the lowest level of suspended solids in the decant flow. This provides the best quality effluent from the secondary process to ensure that the downstream filtration process is optimized.

The Alfa Laval AS-H Iso-Disc Cloth Media Filter provides continuous filtration even during backwash and maintenance. Individual filter elements can be individually monitored for throughput and quality, and can be removed for service without disrupting the filtration process. This ensures reliable and consistent effluent of reuse quality, and significantly reduces long-term maintenance costs.

The combination of robust, high efficiency turbo blowers with Alfa Laval diffusers, provides optimum oxygen transfer efficiency and reliability. Iso-Disc tertiary filtration minimizes the volume of backwash water required, which saves costs of pumping recycle streams and improves the overall hydraulics of the treatment facility.

The optimized process design has resulted in low power consumption for the system. All these benefits help Agri Beef achieve sustainable and efficient operation.