Efficient DIABON® plate heat exchangers give Belgium fertilizer plant "license to operate"

An old-fashioned open cooling system threatened to leave Tessenderlo Chemie’s potassium sulphate fertilizer plant in Ham, Belgium with hydrochloride-acid-contaminated waste streams that would put the facility’s profitability at risk. Alfa Laval had the solution.

DATE 2025-12-18An old-fashioned open cooling system threatened to leave Tessenderlo Chemie’s potassium sulphate fertilizer plant in Ham, Belgium with hydrochloride-acid-contaminated waste streams that would put the facility’s profitability at risk. Alfa Laval had the solution.

A valuable by-product – with a downside

Until 2011, the flue gas exiting a number of Tessenderlo Chemie’s potassium sulphate furnaces was cooled in four absorption towers by running water over graphite-coated tubes to produce a commercially viable concentration of hydrochloric acid (HCI). However, the inefficient system left waste streams containing traces of HCI as well as air and other flue gases. The company was able to reuse these waste streams at their other facilities until a reorganization plan promised to put an end to the practice within four years.

One crucial goal: eliminate waste streams

“There are other benefits. But first and foremost, installing Alfa Laval’s DIABON heat exchangers quite literally gave us a license to continuing operating,” says Ben Bettens, process engineer, Tessenderlo Chemie. “We needed an efficient system in order to eliminate the waste stream from our absorption towers. Otherwise the high cost of disposing of them would threaten the very existence of the plant. The problem was complicated by the highly corrosive nature of hydrochloric acid – only Alfa Laval had the material we needed.”

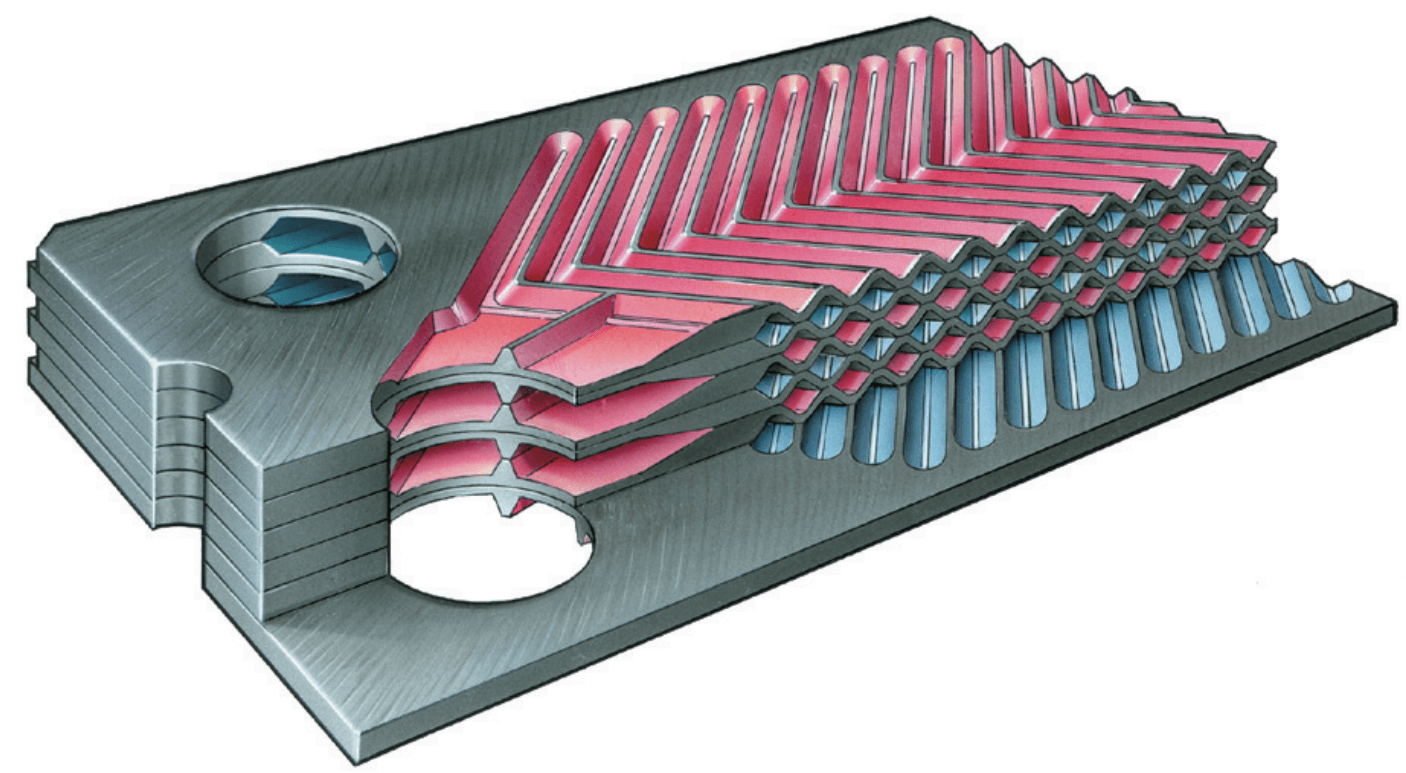

One of the DIABON® heat exchangers in operation at Tessenderlo Chemie.

DIABON plate heat exchangers – a unique solution for corrosive environments

Alfa Laval’s DIABON plate heat exchangers combine the high-efficiency heat transfer benefits of conventional plate heat exchangers with the exceptional corrosion resistance of unique DIABON graphite material. Tessenderlo Chemie ordered a total of 16 DIABON graphite plate heat exchangers to replace open coolers producing high-concentration HCI and an additional 5 to upgrade waste streams.

Mission accomplished – and more

The DIABON plate heat exchangers offer the cooling capacity needed to produce high-quality HCI without leaving an expensive-to-dispose-of waste stream. And they have been doing that successfully for Tessenderlo Chemie since the first one was commissioned in 2011. They have also eliminated the need to replace 20 graphite tubes per year at cost of 5,000 euros each, maintenance is a non-issue and they can be cleaned with CIP (Cleaning-In-Place).

Maximum heat recovery

A combination of high turbulence and counter-current flow offers maximum heat recovery. The principle is simple. Two media flow through channels between corrugated plates, creating a high degree of turbulence in the media. This results in better heat transfer. And counter-current flow allows close temperature approaches, which results in better heat recovery.

“Maintenance is much easier now”

“The DIABON heat exchangers are never opened and we have never needed to replace a plate,” says Bettens. “It’s only cleaning, and we can do that at a low cost with CIP. I estimate it takes half a day per year for each heat exchanger to be cleaned – in the past cleaning took 46 hours. In many cases, we can take one heat exchanger out of service without interrupting production.”

Alfa Laval has “good stuff”

“For manufacturers facing similar operating conditions to ours, I would tell them that Alfa Laval has good stuff,” continues Bettens. “Technically it is a very good solution. And we have a very good relationship with Alfa Laval.”

Fast facts

The customer

Tessenderlo Chemie is an international speciality group that provides solutions for global needs in food, agriculture, water management and efficient re-use of natural resources. Headquartered in Belgium, the group operates at more than 100 locations in 21 countries.

The challenge

A company reorganization meant that hydrochloride-acid-laden waste streams from a potassium sulphate plant in Ham, Belgium would no longer be reusable at other facilities. So the plant needed an efficient, corrosive-resistant cooling solution to eliminate waste streams.

The solution

- Total of 6 x 2 (12) DIABON heat exchangers S10 F100 with 130pl replace 6 x 2 (12) open coolers.

- 4 DIABON heat exchangers S10 F100 with 30pl replace 4 open coolers.

- 5 new DIABON heat exchangers S10 F100 with 30p

Alfa Laval DIABON® heat exchanger

Alfa Laval and SGL Group Germany, worked together to develop DIABON graphite plate heat exchangers. This collaborative effort combines Alfa Laval’s plate heat exchanger know-how with SGL Group’s expertise in graphite process equipment. The resulting product combines the high-efficiency heat transfer benefits of conventional plate heat exchangers with the exceptional corrosion resistance of graphite material.

This makes Alfa Laval DIABON plate heat exchangers ideal for duties in which metallic plates with low corrosion resistance cannot live up to service life requirements, and where the heat transfer efficiency of heat exchangers that use materials such as glass and Teflon® is unacceptably low. Compared with other graphite solutions, such as graphite blocks, Alfa Laval DIABON plate heat exchangers provide the additional advantages of reduced fouling and full access to the heat transfer surface.

Customer's voice

The problem was complicated by the highly corrosive nature of hydro-chloric acid – only Alfa Laval had the material we needed.

Ben Bettens

Process Engineer

The benefits

- No HCI waste streams, so no crippling disposal costs

- Higher thermal performance

- Environment protection: no open system

- Less downtime: fewer cleaning hours and in many cases one heat exchanger can be taken out of service for cleaning without interrupting production

- OPEX decrease: old coolers consisted of 100 graphite tubes, 20% had to be replaced every year = 5,000 euros per tube

- Easy cleaning with CIP