Rosneft Tuapse fuels up its energy recovery

Significant energy savings and reductions in emission from the heater

DATE 2023-11-28In 2006, the Rosneft Tuapse refinery in Southern Russia decided to improve energy recovery in one of its three crude preheat trains.

A total of three Compabloc heat exchangers with plates made of 254 SMO were installed. One, with a surface area of 100 m2, replaced two traditional shell-and-tube units with

a total surface area of 570 m2 that were unable to tackle the requirement for more effective energy recovery. The other two Compabloc units were installed to deal with new energy

recovery duties.

The Compablocs were brought on line in September 2006. Among the energy-saving objectives achieved was a 8–10°C increase in the furnace inlet temperature of the crude.

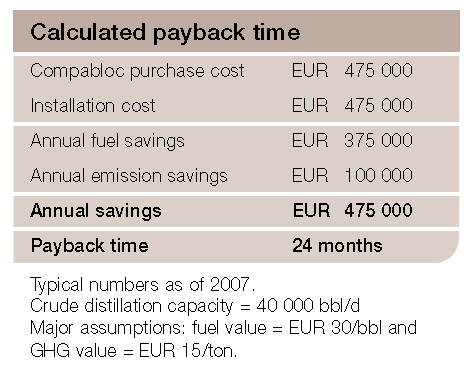

This resulted in both significant energy savings and reductions in emission from the heater.

Products

The Alfa Laval Compabloc welded heat exchanger is probably the most compact and efficient heavy-duty heat exchanger in the world.