Reduced maintenance costs

The Kakogawa coke plant is a technically advanced production facility. The computerized system used in the plant's production line features state-of-the-art information technology that enables the companyto achieve a high level of automation, continuous operation and great efficiency.

DATE 2025-12-16The Kakogawa plant has also implemented the latest developments in environmental technology. The plant was granted ISO 14001 certification in 1998 and achieved OHSAS 18001 status in 2003.

The Kakogawa plant produces 2.5 million tons of coke per year in addition to a number of products related to coke production. The plant is owned by the Kansai Coke and Chemicals Co. Ltd, whose major shareholders are Mitsubishi Chemical and Kobe Steel. These two companies are also the main end users of the plant’s products. The plant is actually located on the same premises as Kobe Steel, and most of the coke oven gas produced here is supplied to Kobe Steel for use in the company’s two blast furnaces.

Cost-effective replacement

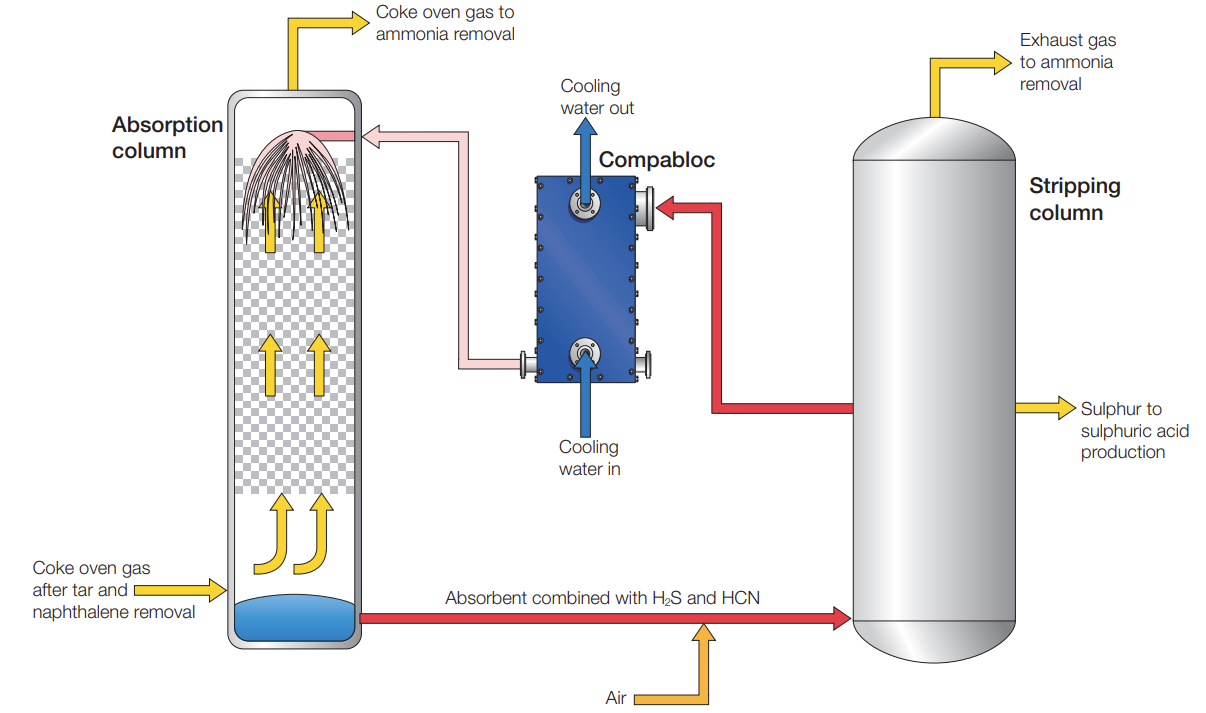

Until 2000, Kakogawa used four shell-and-tube heat exchangers with a total shell area of 2400 m2 as absorbent coolers in the sulphur removal section of its plant. However, these were prone to heavy fouling as the absorbent contains sulphur particles. They required cleaning twice a year using water jets, which proved to be a very time-consuming and costly process.

In 2000, corrosion in the four shell-and-tube heat exchangers had reached such a serious state that they all needed replacing. The Kakogawa management therefore decided to investigate more modern process equipment. However, replacement with a standard plate heat exchanger was a problem, as it was difficult to find a gasket rubber that could withstand the effects of the absorbent chemicals. A gasket-free, all-welded plate heat exchanger could only be used if it was possible to regularly open and clean the unit. This made Alfa Laval Compabloc heat exchangers the only logical solution.

Kakogawa purchased Compabloc heat exchangers with a total surface area of around 500 m2, thus providing the plant with a significantly less expensive solution in terms of initial investment and installation. These Compabloc units subsequently also proved to be much less expensive in terms of maintenance. Four Alfa Laval Compabloc heat exchangers are now installed in the desulphurization and decyanization part of the process resulted in performance that was described as being just like new. To date, the two Compablocs installed in 2002 have not required service at all, and were still operating without any problems in September 2004.

Mr T. Iwanaga, the assistant manager in the gas refining section says, “The staff at the Kakogawa coke plant are very satisfied with their decision to replace the shell-and-tube heat exchangers with the four Compablocs. Compared with the shell-and-tube heat exchangers, the Compablocs have required significantly less service. Over a period of three years, they’ve only required backflushing. We’re considering using Compablocs for other duties in our COG plant, not only because they are more compact, but also because they involve lower investment costs.”

Meeting different needs

Over the years, the Kakogawa coke plant has also used Alfa Laval equipment for a number of other purposes, as part of a long-standing process of collaboration. Eight Alfa Laval spiral heat exchangers were installed in the early 1980s as benzolized/debenzolized oil interchangers in the light oil recovery section of the plant. Another five spiral heat exchangers are used for different duties in the sulphuric acid section. A standard gasketed Alfa Laval plate heat exchanger is used to recover heat for pre-heating the boiler feed water by means of ammonia liquor. Five semi-welded Alfa Laval plate heat exchangers have been used as final coolers in the coke oven gas refining line since 1987.

The compact, fully welded Compabloc heat exchanger is designed to operate with a wide range of aggressive media and at high temperatures and pressures.

Benefits

- lower investment costs

- less maintenance cost and time

- compact design

- less fowling