Exclusive air-conditioning

A Mexican resort hotel stays cool thanks to heat exchanger technology.

DATE 2025-12-11Flanked by the Caribbean Sea and the Nichupté Lagoon, the exquisite Cancún Palace all-inclusive resort on the Yucatán Peninsula in Mexico has been running an air-conditioning and swimming pool-heating system based on Alfa Laval heat exchangers since late 2006.

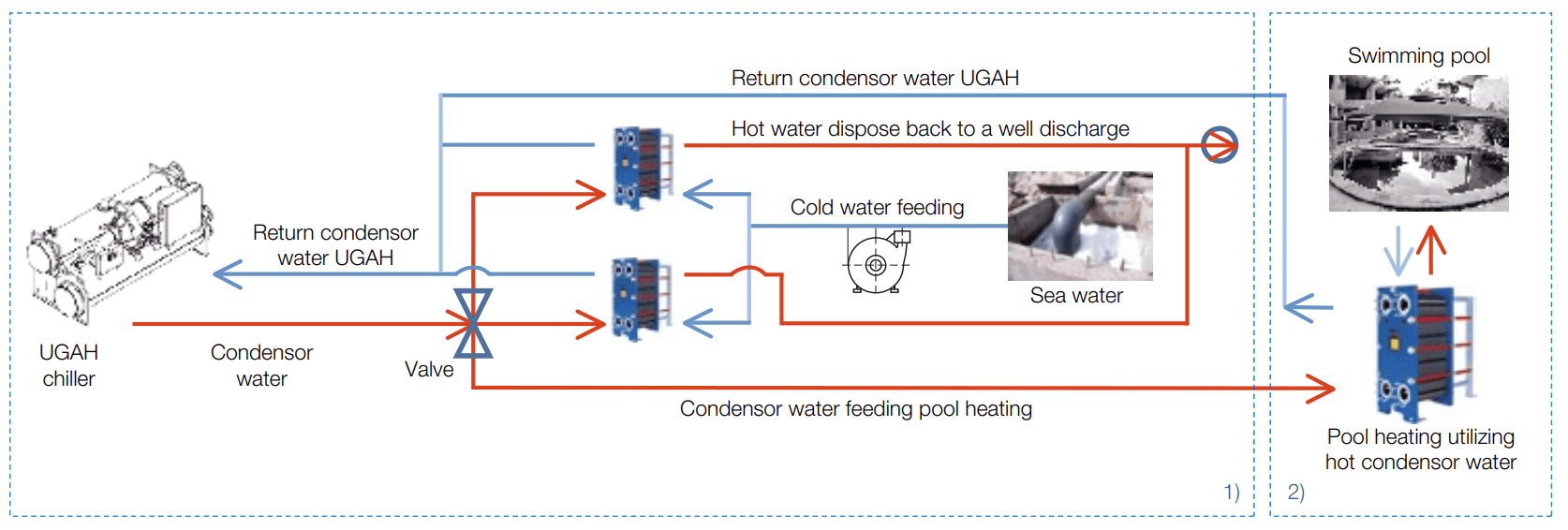

The cooling system uses three Trane-branded water-cooled chillers with centrifugal compressors (each with 887 tons of refrigeration capacity) that are chilled by bountiful, free sea-water obtained from a well close to the ocean. The condensers on each of these chillers/compressors are cooled by two Alfa Laval M10 titanium-plated heat exchangers, meaning that a total of six heat exchangers are used for the condensers. This provides a much cheaper solution than other possible alternatives. Titanium is used to prevent corrosion from the seawater.

The cooling system uses three Trane-branded water-cooled chillers with centrifugal compressors (each with 887 tons of refrigeration capacity) that are chilled by bountiful, free sea-water obtained from a well close to the ocean. The condensers on each of these chillers/compressors are cooled by two Alfa Laval M10 titanium-plated heat exchangers, meaning that a total of six heat exchangers are used for the condensers. This provides a much cheaper solution than other possible alternatives. Titanium is used to prevent corrosion from the seawater.

An additional two M15 titanium-plated heat exchangers are used to heat the hotel’s pools using the condensers’ warm-water discharge as a heating agent.

Proven technology

For local contractor Tecnoterma, which has worked with Alfa Laval equipment for many years, the system’s reliability and its comparatively small footprint laid the groundwork for similar air-conditioning installations at four other resorts on the Riviera Maya in Cancún. The latest of these was built in 2007.

Easy exchange

During the planning stage of the original installation at Cancún Palace Resorts, a more traditional cooling-tower system was considered instead of using air-cooled condensers. The main reason for the decision to use the latter system was the risk that the aggressive ambient seawater climate would cause the fins to corrode. It soon became clear that a plate heat exchanger system had strong advantages over a cooling-tower system.

These advantages include no evaporation, a closed loop system (important in a freshwater-deprived area such as Cancún), no cost for the cooling seawater, no need for water treatment, no fan belts and minimal maintenance.

Energy savings

Trane water-cooled condensers have an efficiency of 0.436 kW/TR, while Trane air-cooled condensers have an efficiency of 1.16 kW/TR. This results in a 62 percent savings in power consumption when only the water-cooled chiller is used. It should also be considered that the condensers discharge heat for domestic hot-water pools, recover at least -6,67 °C (20 °F) in this system.

In addition, the water-temperature setting of an air-conditioning system based on plate heat exchangers and seawater cooling is 5 °C (41 °F), compared to 12 °C (53,5 °F) for a cooling-tower system. A general estimate of the chiller’s electricity consumption is that, for every degree Celsius that the condenser’s water temperature is lowered, a 1-1.5 percent reduction in consumption is achieved.

Symbolic system flow chart. Cut-out of chiller/condensor side of system 1) in reality cocists of three identical connected systems. Cut-out of pool heating side 2) in reality consists of two identical connected systems.

Products

The following plate heat exchanger models was installed:

- M10 titanium-plated heat exchangers

- M15 titanium-plated heat exchangers

The plate heat exchangers use the condensers' warm water discharge as a heating agent.

Customer facts

- Cancún Palace Resorts with 601 rooms

- Located on the Yucatán Peninsula in Mexico

- Contractor: Tecnoterma

Solution

- Air-conditioning system based on a central chilled seawater system that supplies cold freshwater to cool the condenser of each chiller.

- Cooling-tower technology was originally considered, but it was soon determined to be more expensive and more maintenance intensive.

- Cooling effect: 21-25°C

- (70-77°F) inside and outside temperatures of 36 °C (97°C)

- Extensive energy savings: 62% savings when using water-cooled chiller instead of air-cooled chiller, plus the opportunity to heat pools at no additional cost.

- Additional 7-10,5% savings achieved by using seawater-cooled condensers instead of cooling-tower system.