Maximizing hygiene unlocking energy savings

A leading beverage producer explored energy savings potential when recovering heat from the cooling process. By upgrading to Alfa Laval H8 hygienic heat exchangers, the company achieved annual savings of EUR 137,000 without compromising hygiene standards.

DATE 2026-02-17

How to cut energy consumption and operational costs?

In the food and beverage industry, hygiene is non-negotiable. But today’s manufacturers also face growing pressure to optimize operations, reduce energy use and lower their carbon footprint. That was also the case at a leading beverage producer in China.

The company was challenged by high energy consumption during the cooling phase of tea production. After boiling and centrifugation, the tea was cooled directly using tower water in a process without heat recovery. This meant wasted energy and unnecessary costs.

The solution: Efficient heat recovery

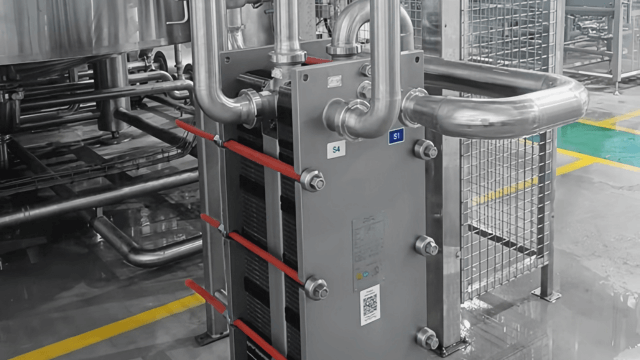

In collaboration with the beverage producer, the local Alfa Laval partner and Alfa Laval application specialists, process line upgrades were identified and documented to achieve substantial energy savings.

Before the upgrade, tea was cooled from 90°C to 40°C using

tower water only – no heat recovery.

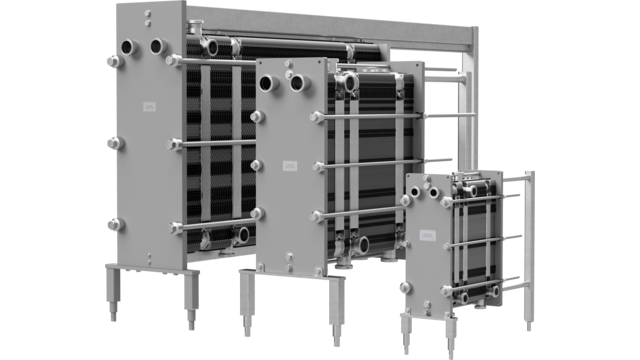

After the upgrade, an Alfa Laval H8 plate heat exchanger cooled tea to 45°C using RO water (reverse osmosis water), reducing tower water use to only the final cooling step from 45°C to 40°C. The heated RO water was then reused in the mixing section, cutting steam consumption significantly

Our goal is to help customers optimize operations today while supporting long-term sustainability ambitions. This upgrade delivered significant savings without compromising hygiene.

Edward Deng, Business Unit Manager at Alfa Laval China

Substantial savings obtained

The simple, yet effective process upgrade enabled the beverage producer to recover and reuse thermal energy. The calculated annual steam savings amount to approx. 3,700 tons, corresponding to annual savings of more than EUR 137,000.

“This upgrade project is a great example of how we can help food and beverage producers upgrade inefficient heat exchanger technology, achieve optimum plate configurations, change cleaning and maintenance programmes and reuse waste energy in other applications,” said Edward Deng