Embrace bag in box packaging to meet the increasing demand from consumers

Over the next five years, demand for food and beverage bag-in-box (BIB) packaging will increase exponentially. To meet the food industry demand, manufacturers need smart bag-in-box packaging and filling solutions.

DATE 2023-11-28There are many good reasons to use environmentally friendly bag-in-box packaging. Among them:

- BIBs reduce the carbon footprint of packaging by eight times compared to glass bottles,

- BIBs use 85% less plastic than rigid containers

- BIBs cut transport emissions and logistics costs

- BIBs reduce the water and energy required to produce packaging compared to other packaging types

- One truck transporting BIBs carries the same product volumes as seven trucks carrying 75 cl bottles

- More than 75% of the corrugated cardboard used for BIB packaging is fully recyclable, renewable and biodegradable

- Recyclability minimizes waste going to landfills and ending up in our waterways and oceans

Advantages of BIB packagingBesides being a more sustainable packaging alternative, BIBs offer hermetically sealed packaging engineered to contain a specific type of product. Airtight packaging improves hygiene, safeguards product integrity, and extends product shelf life by preventing the ingress of air, oxygen, or other gases.

BIB filling equipment portfolio that is convenient and flexible

Alfa Laval provides both aseptic and non-aseptic filling equipment for bag-in-boxes, ranging from consumer packaging in three-litre cartons to industrial packaging in drums and containers from 200 to 1,000 litres in size.

Alfa Laval aseptic fillers. These are used to fill dairy products, such as ultra-high temperature or UHT milk, ice cream mix, whipping cream, and cream with high-fat content, among other products.

- The Alfa Laval Pilot aseptic filler is an entry-level aseptic filler for BIB (3-20 litres), 200-litre drums, and larger volume bags with a trunk using different filling valves.

- By far, our most popular model is the Alfa Laval Compact aseptic filler for heavy-duty industrial requirements. Competitively priced, it works well on multi-format lines, filling viscous fluids at 20°C into 3/20L and 200L/1000L bags and containers on the same line. Easy-to-configure to customers’ exact requirements, these tested, pre-assembled, plug-and-play modules can fill a broad range of food and beverage products, operating either automatic or semi-automatic mode, into 200-litre and 1000-litre bags.

- The Alfa Laval High speed low acid (HS-LA) aseptic filler is a versatile aseptic bag-in-box filling system for use with juices, beverages, purées and dairy products. It meets FDA regulations and operates at higher speeds with higher precision and higher reliability because it is driven by brushless electric servomotors.

Alfa Laval non-aseptic fillers. These are typically used when the product is: hot-filled enabling pasteurization to take place in the container; stable at ambient temperature; or, filled cold and kept in a cold chain such as orange juice, fresh milk or extended shelf life or ESL milk.

- Alfa Laval Piccolo filler is a compact, semi-automated, entry-level module that is easy to operate and easy to maintain.

- Alfa Laval Grande filler is an automated, high-speed, high-capacity system for shelf-stable liquid products, such as wine, water, mayonnaise, tomato ketchup, post-mix products, syrups and vegetable oils.

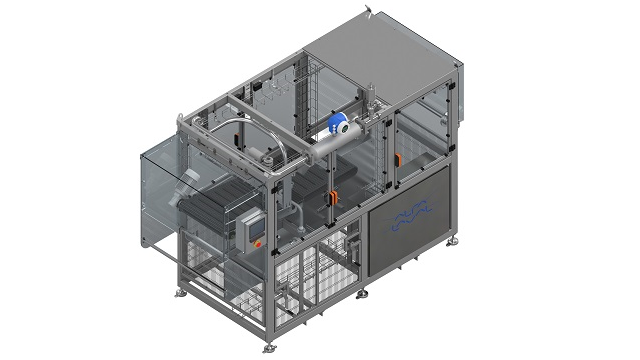

- Alfa Laval Combibox is a mono-block cartoning system that forms the carton, inserts the bag inside, and closes and seals the carton, using tape or hot melt glue. The Combibox is the result of cooperation with a major Italian packaging machinery company.

Learn more about the Alfa Laval bag-in-box portfolio here. Or your local Alfa Laval representive.