Beer concentrate, a new generation of beer

Great-tasting draft beer from beer concentrate? You bet! Beer concentrate is a new generation of beer and is every bit as good as fresh draft beer on tap – that’s what taste tests reveal about rehydrated beer from concentrate.

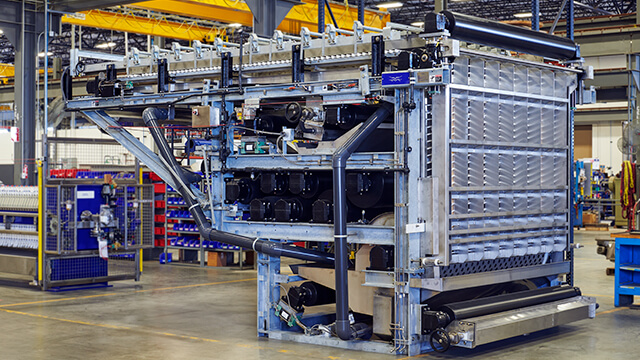

DATE 2024-08-13Great-tasting draft beer from beer concentrate? You bet! Beer concentrate is a new generation of beer and is every bit as good as fresh draft beer on tap – that’s what taste tests reveal about rehydrated beer from concentrate. The Alfa Laval RevosTM draft dispense system delivers the same great-tasting beer and beverages from concentrate while, at the same time, reducing emissions, water consumption and energy costs related to beer production and distribution.

Choose between Revos draft dispense systems for bar cellars, and Revos draft dispense mobile systems for cafés and temporary or crowded venues, such as concerts or sporting events. Both come with integrated monitoring systems to ensure the quality of every pour (temperature, carbonation, alcohol by volume, flow rate).

Brewery taste tests

Experts subjected reconstituted European lager from a Revos-produced concentrate to an in-depth sensory evaluation with taste, aroma, and mouthfeel among the criteria. Test results revealed a taste match between an original beer and a rehydrated beer.

Up to six times more efficient than regular bulk transport

Hauling kegs and other bulk containers to bars, cafés and restaurants are fossil-fuel intensive. Minimizing bulk transport costs and carbon footprint is a logical way to reduce beer makers’ and beer lovers’ impact on the environment.

Transporting concentrate is up to six times more efficient than transporting regular beer and beverages. Using Revos draft dispense with the Alfa Laval Revos concentration system helps beer manufacturers, as well as bars, cafés and restaurants, cut transport costs. It also boosts their sustainability credentials while reducing costs and emissions related to packaging, storage, shipping and refrigeration.

Why use Revos draft dispense?

Serving alcoholic and non-alcoholic concentrates directly from the tap with the Revos draft dispense system:

- Can save more than €20 per hl on keg transport

- Reduces the CO2 footprint of breweries, beverage manufacturing facilities and serving establishments while contributing to meeting sustainability goals

- Ensures pour quality using the Alfa Laval Revos draft dispense monitoring system

Quality management of beverages on tap

The Revos draft dispense monitoring system ensures the quality of every pour. When using the Revos draft dispense cellar and mobile systems, the monitoring system provides an overview of the alcoholic and non-alcoholic concentrates on draft. A wireless network connects the Revos draft dispense units to the control system and relays quality information to both bar and brand owners.

Alfa Laval Revos portfolio

The Revos draft dispense system is part of the Alfa Laval Revos beer and beverage concentration portfolio, which includes the Revos concentration system and the Revos concentration system with dealcoholization and dearomatization.