Recovering lost belt press performance

For decades, two Alfa Laval ASH belt filter presses had supported a major refinery in the southern United States. Built in 1987 and 1992, the 2.0-meter-wide units delivered reliable performance in a demanding environment. However, after years of exposure to harsh refinery conditions, the equipment began to show its age, prompting discussions about replacement. Instead, Alfa Laval identified a way to restore performance at a much lower cost.

DATE 2026-02-17A refinery environment can be tough on equipment, as operations place continuous mechanical stress on belt press dewatering systems. One of the two presses, originally a Klampress Mark II, had been upgraded to a Type 85 during its lifetime to increase performance without full replacement. The second press was built as a Type 85 from the start. Wear and tear on both machines had begun to take its toll, as the belt presses were no longer able to handle the desired feed rate or consistently maintain the required cake dryness. In the prior months, the facility had also been required to make unplanned repairs to the machines.

At large facilities, components such as rollers, hydraulic seals, wear strips and steering systems naturally degrade over time. Even small deviations, such as belt misalignment, worn bearings, or weakened frames can impact how well a belt filter press performs. This can result in thousands of additional pounds of sludge per day and rising operational costs, especially when sludge requires special handling or transport to a distant landfill.

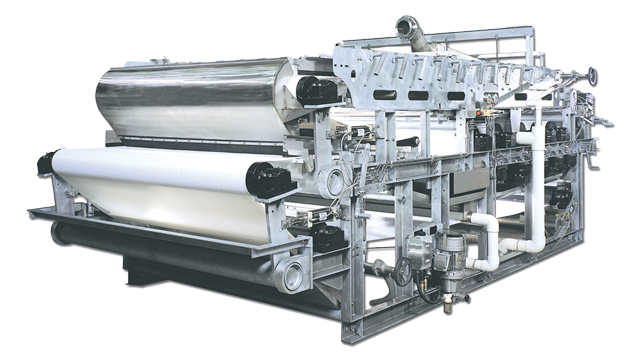

Example of an Alfa Laval ASH belt filter press prior to rebuild at the service center

When the refinery decided to call Alfa Laval, the solution initially under consideration was to replace the two machines. The belt filter presses had served the facility well, but 30 years is a long service life for equipment operating in this application. However, before committing capital to completely new machines, Alfa Laval’s water and wastewater specialist identified an opportunity to achieve the same performance goals at a fraction of the cost.

Rather than replacing the equipment, Alfa Laval recommended a partial onsite rebuild combined with hands-on operator training. This approach addressed both underlying mechanical issues and process-operational factors on the existing sludge dewatering presses that influence long-term efficiency. It also aligned with Alfa Laval’s commitment to helping customers optimize resources and extend equipment life.

Example of an Alfa Laval ASH belt filter press after rebuild at the service center

Executing the rebuild

An Alfa Laval certified field service technician conducted a detailed inspection, working through a prepared list of itemized repairs and adjustment on site. Key component replacements included:

- Multiple rollers and bearings

- All support wear strips under the filter belts

- Rubber seals

- Hydraulic motor

- Tensioning and steering cylinders

- Tracking valves and steering paddles

Each component was installed, aligned and tuned to restore optimal belt tracking, pressure and flow conditions. At the same time, operators received hands‑on training focused on identifying early signs of mechanical or process deviation, empowering them to keep the belt presses running at peak performance.

By choosing the rebuild option provided by Alfa Laval instead of replacing the equipment, the refinery saved over USD 200,000 in expense. The presses returned to stable, high‑quality operation with consistent cake dryness and reduced operator intervention. Just as importantly, the refinery benefited from fewer process interruptions and gained confidence that all parts used were genuine OEM components.

Highlighted Technologies

Rebuild Service

Belt Press retrofit with OEM-quality parts, advanced upgrades and complete service handled by Alfa Laval certified field service technicians

Cost savings

The refinery realized more than USD 200,000 in cost savings

Hands-on operator training

Operators were trained to recognize key process indicators and operating conditions that signal when adjustments should be made